Microsystem optical fiber gas sensor, sensing system and sensing method

A gas sensor and micro-system technology, which is applied in the fields of instruments, scientific instruments, color/spectral characteristic measurement, etc., and can solve the problems of complex system structure, high requirements for sensing environment and difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Further illustrate the present invention below in conjunction with accompanying drawing:

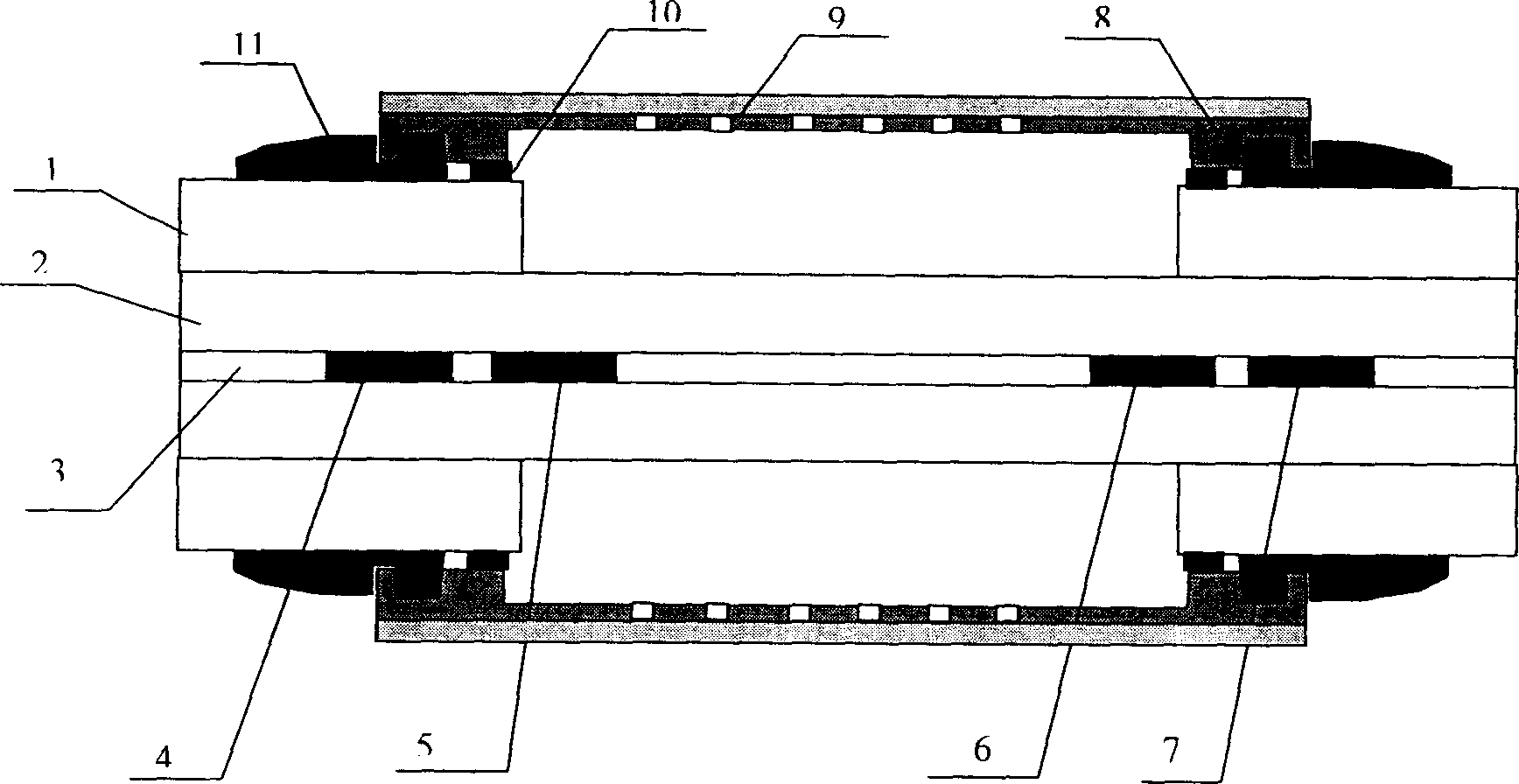

[0032] see figure 2 , The structure of the sensor includes: fiber coating 1, fiber cladding 2, fiber core 3, short period fiber grating 4, long period fiber grating LPFG15, long period fiber grating LPFG26, short period fiber grating 7, protective cover 8 , dust filter thin layer 9, curing glue 10, transitional buffer sleeve 11. Among them, the optical fiber material is quartz, and two long-period fiber gratings with a length of about 20 mm are arranged on a section of optical fiber that has removed the plastic protective coating; the two long-period fiber gratings are 10 cm apart, and their coupling center wavelengths are both 1160 nm. Its 3dB bandwidth is 10nm, its coupling efficiency at the central wavelength is 99.7%, and its wavelength bandwidth at which the coupling efficiency is greater than 99% is 3.5nm; there are two short-period optical fibers outside the two long-peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com