Water filtering device with double-layer filter material,modified filtering material and its preparation method

A double-layer filter material and water filtration technology, applied to loose filter material filters, filter separation, separation methods, etc., can solve the problems of high cost of enhanced filtration methods, difficult algae adsorption, and short filtration cycle, etc., to achieve easy application and popularization, the effect of simple preparation method and long filtration period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

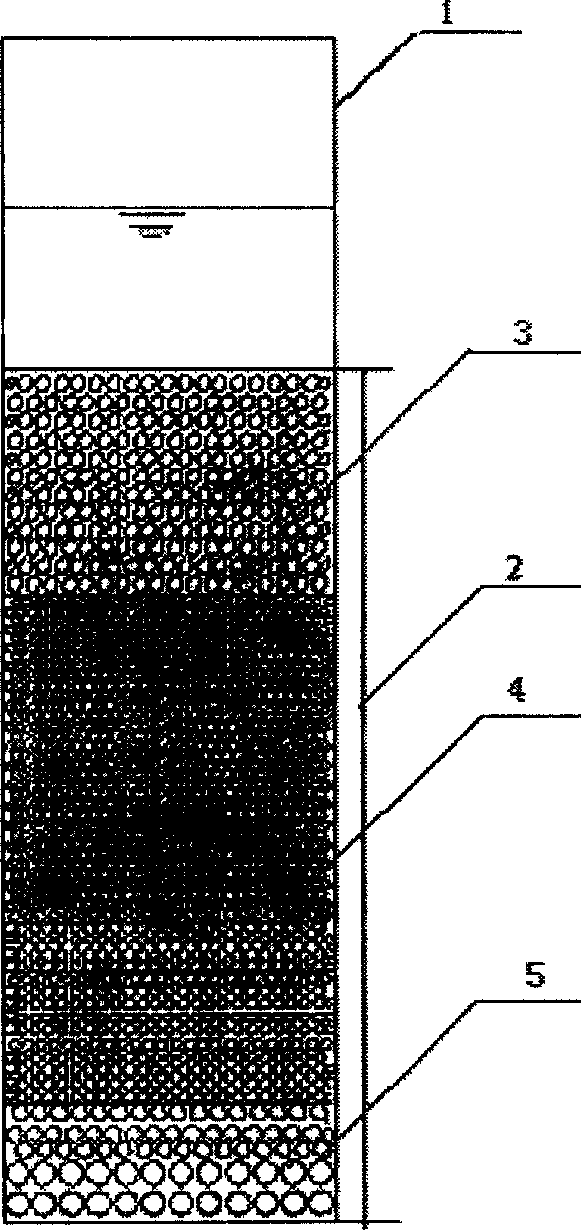

[0006] Specific implementation mode one: refer to figure 1 , the present embodiment is a water filtration device with double-layer filter material, which includes a water treatment reactor 1 and a filter material 2 installed in the water treatment reactor 1; the upper layer of the filter material 2 is anthracite with a thickness of 200 mm to 400 mm The filter material layer 3, the lower layer of the filter material 2 is a modified filter material layer 4 with a thickness of 500mm-800mm, wherein the particle size of the anthracite filter material is 0.8mm-1.8mm, and the particle size of the modified filter material is 0.5mm-2.0mm .

[0007] The upper anthracite filter material layer 3 of the filter material 2 of the present embodiment can remove some impurities in the water body, improve the dirt-holding capacity of the filter device, help to improve the water quality passing through the modified filter material layer 4, and prolong the modified filter material layer 4. Filtra...

specific Embodiment approach 2

[0008] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the modified filter material layer 4 and the anthracite filter material layer 3 are all graded with different particle sizes, and the coefficient of inhomogeneity K 80 are less than 2.0.

specific Embodiment approach 3

[0009] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the supporting layer 5 is laid below the modified filter material layer 4, and the supporting layer 5 is made of natural pebbles or gravel materials; the supporting layer Layer 5 is at least one layer, and the thickness of each layer is 50-110 mm, and the particle size of natural pebbles or gravel materials increases layer by layer from top to bottom.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com