Solid-state imaging device and its manufacturing method

A technology of a solid-state imaging device and a manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, image communication, etc., and can solve problems such as defects and difficulty in miniaturizing the imaging area 107

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

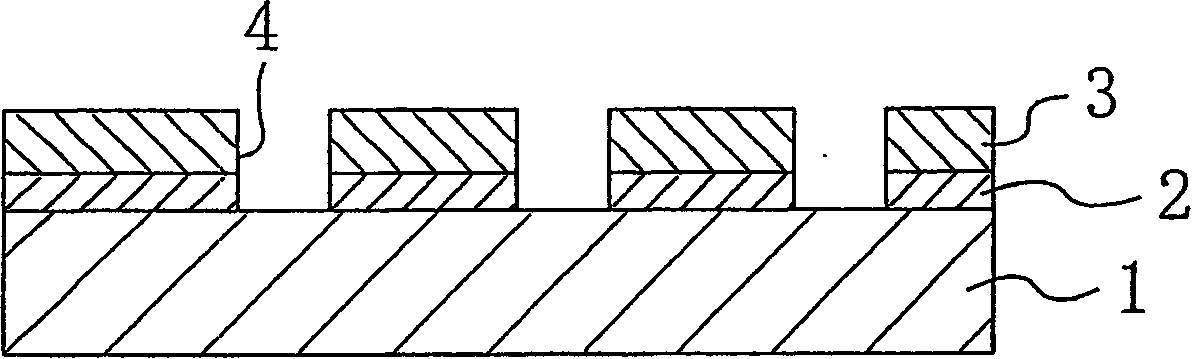

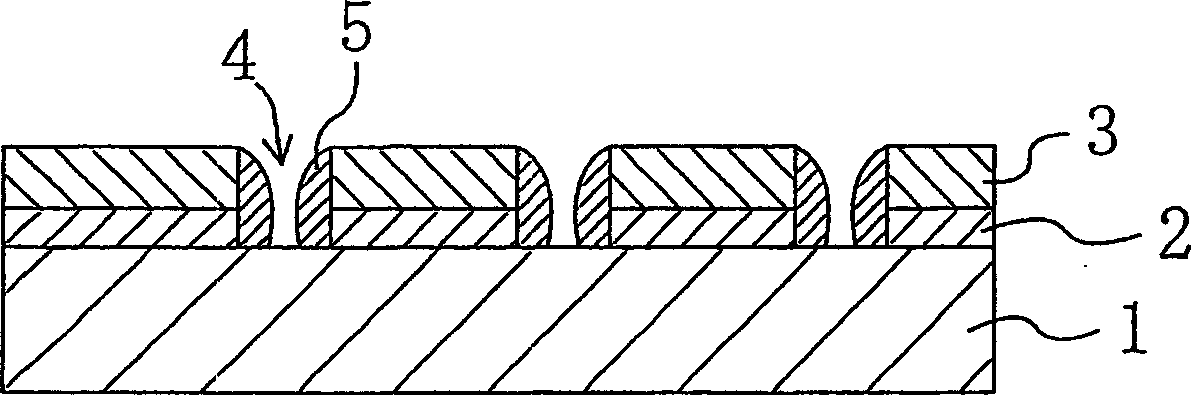

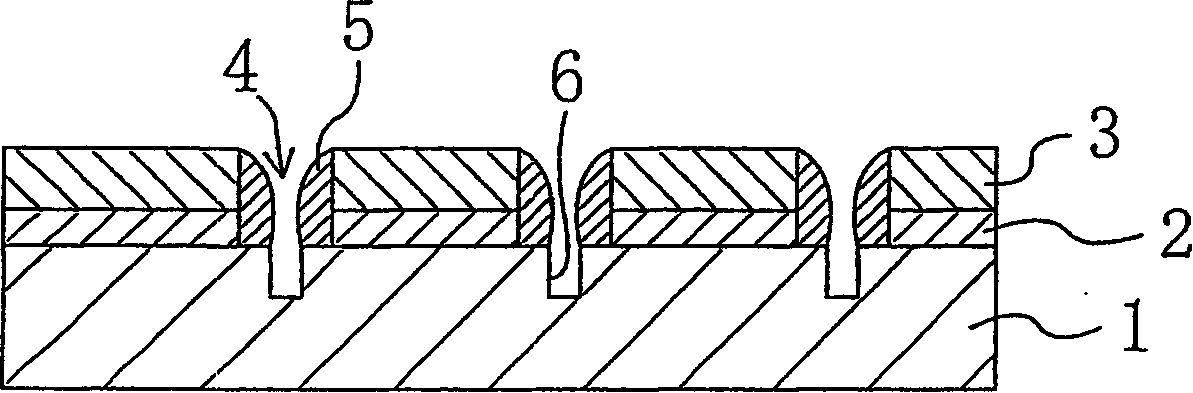

[0118] Figure 1A ~ Figure 1F It is a cross-sectional view showing a step of forming an element isolation region in the manufacturing process of the solid-state imaging device according to the first embodiment.

[0119] In the manufacturing process of the solid-state imaging device of this embodiment, first, in Figure 1A In the shown steps, a liner insulating film 2 made of a silicon oxide film with a thickness of about 1 to 50 nm is formed on a semiconductor substrate 1 . On the liner insulating film 2, an oxidation resistant film 3 made of a silicon nitride film or the like with a thickness of about 50 to 400 nm is formed. Furthermore, on the oxidation-resistant film 3, a resist (not shown) having openings in predetermined regions is formed.

[0120] Then, by etching using the resist as a mask, opening 4 penetrating liner insulating film 2 and oxidation resistant film 3 and exposing a predetermined region in the upper surface of semiconductor substrate 1 is formed. After...

no. 2 Embodiment approach

[0134] Figure 2A ˜ FIG. 2F are cross-sectional views showing a step of forming an element isolation region in the manufacturing process of the solid-state imaging device according to the second embodiment.

[0135] In the manufacturing process of the solid-state imaging device of this embodiment, first, in Figure 2A In the shown steps, a liner insulating film 2 made of a silicon oxide film with a thickness of about 1 to 50 nm is formed on a semiconductor substrate 1 . On the liner insulating film 2, an oxidation resistant film 3 made of a silicon nitride film or the like with a thickness of about 50 to 400 nm is formed. Furthermore, on the oxidation-resistant film 3, a resist (not shown) having openings in predetermined regions is formed.

[0136] Then, by etching using the resist as a mask, opening 4 penetrating liner insulating film 2 and oxidation resistant film 3 and exposing a predetermined region in the upper surface of semiconductor substrate 1 is formed. After tha...

no. 3 Embodiment approach

[0151] Figure 3A ~ Figure 3D It is a cross-sectional view showing a step of forming an element isolation region in the manufacturing process of the solid-state imaging device according to the third embodiment.

[0152] In the method of manufacturing the solid-state imaging device of this embodiment, first, in Figure 3A In the shown steps, a liner insulating film 2 made of a silicon oxide film with a thickness of about 1 to 50 nm is formed on a semiconductor substrate 1 . On the liner insulating film 2, an oxidation resistant film 3 made of a silicon nitride film or the like with a thickness of about 50 to 400 nm is formed. Furthermore, on the oxidation-resistant film 3, a resist (not shown) having openings in predetermined regions is formed.

[0153] Then, by etching using the resist as a mask, opening 4 penetrating liner insulating film 2 and oxidation resistant film 3 and exposing a predetermined region in the upper surface of semiconductor substrate 1 is formed. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com