Electroplating effluent treatment method

A technology for electroplating wastewater and treatment method, which is applied in the fields of metallurgical wastewater treatment, heating water/sewage treatment, combustion methods, etc., can solve the problems of high engineering cost and treatment cost, poor adaptability, unsuitable for wastewater treatment, and simplify the operation steps. , the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

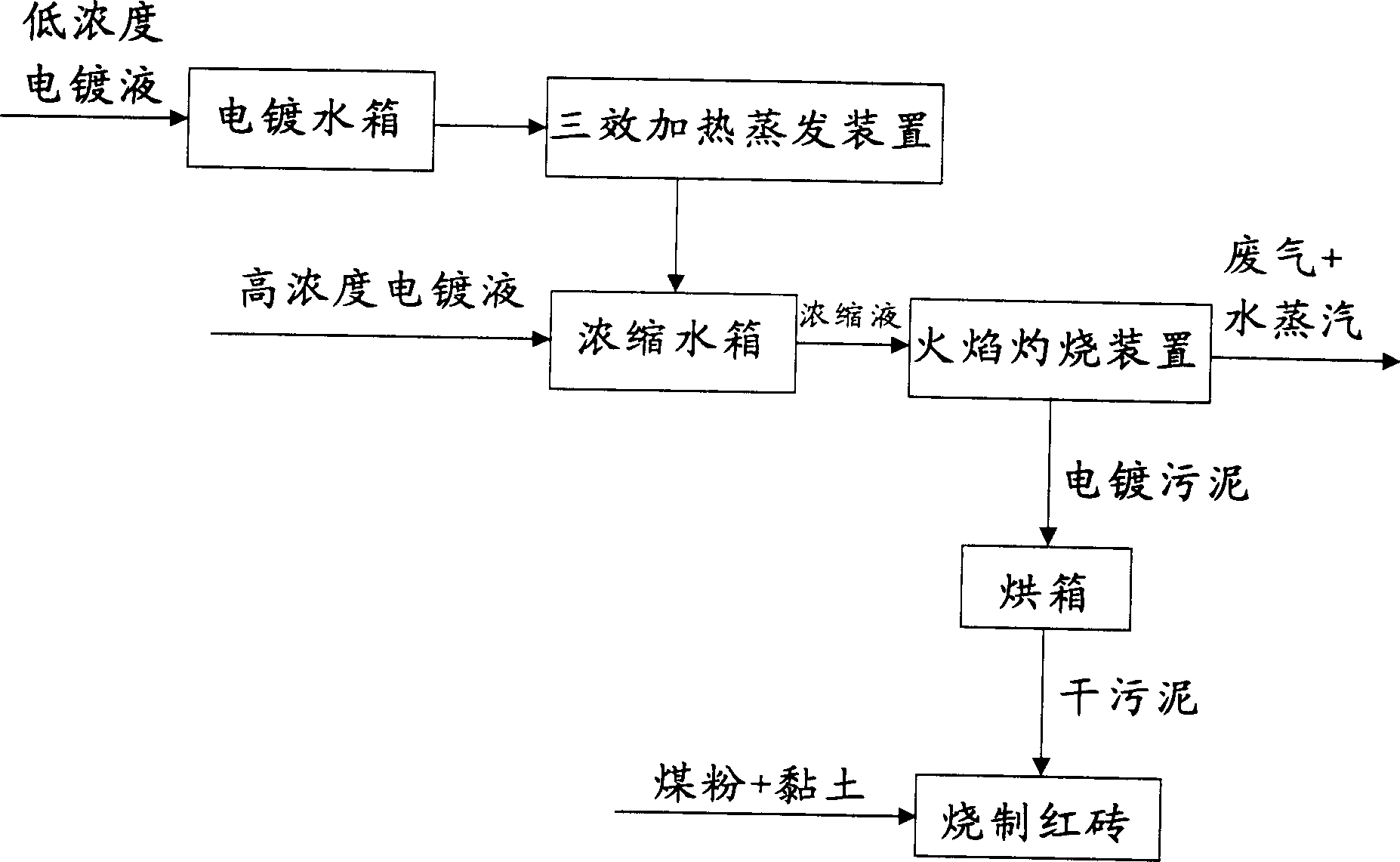

Image

Examples

Embodiment 1

[0050] Cr in automobile manufacturing electroplating wastewater 6+ The concentration was 78 mg / l and the organic matter concentration was 810 mg / l. The electroplating wastewater was sent to an evaporation tank for evaporation and concentration at 90° C. for 3 hours to obtain a concentrated solution with a water content of 35%.

[0051] The concentrated solution is directly sprayed into a high-temperature flame in the form of water mist through a nozzle for combustion to obtain electroplating sludge with a moisture content of 8%. Among them, the flame burning device uses natural gas as the heat source, the volume ratio of natural gas and air is 3.5:7, the calorific value of natural gas is 8700 kcal / m3, the pressure of natural gas is 0.2MPa, the pressure of air is 0.65MPa, and the flame temperature is 950°C . The exhaust gas is shown in Table 1.

[0052] The electroplating sludge was sent to an oven, and dried at 400° C. for three and a half hours to obtain dry sludge with a ...

Embodiment 2

[0054] Cr in galvanized rinse solution 6+ The concentration of the organic matter is 91mg / l, the concentration of the organic matter is 740mg / l, the Cr in the deplating solution 6+ The concentration of organic matter is 167mg / l, and the concentration of organic matter is 940mg / l.

[0055] The rinsing solution is recovered to the electroplating water tank, and then evaporated and concentrated by using a three-effect heating evaporation device to obtain a concentrated solution with a water content of 40%. The temperature of the three-effect heating and evaporating device is: 90°C for the first effect, 80°C for the second effect, and 70°C for the third effect; the vacuum degree is: 0.04 atmosphere for the first effect, 0.05 atmosphere for the second effect, and 0.06 atmosphere for the third effect.

[0056] The concentrated solution and the deplating solution are sent to the concentrated water tank, and then directly sprayed into the high-temperature flame through the nozzle in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com