Nano coating process for metal surface

A nano-coating and metal surface technology, which is applied to the surface strengthening and repair of metal materials, worn and scrapped parts, key parts of mechanical equipment and areas prone to corrosion, can solve the problems of poor coating performance, inconvenient operation, and bonding strength. Insufficient and other problems, to achieve the effect of performance improvement, enhanced bonding force, and improved metal surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

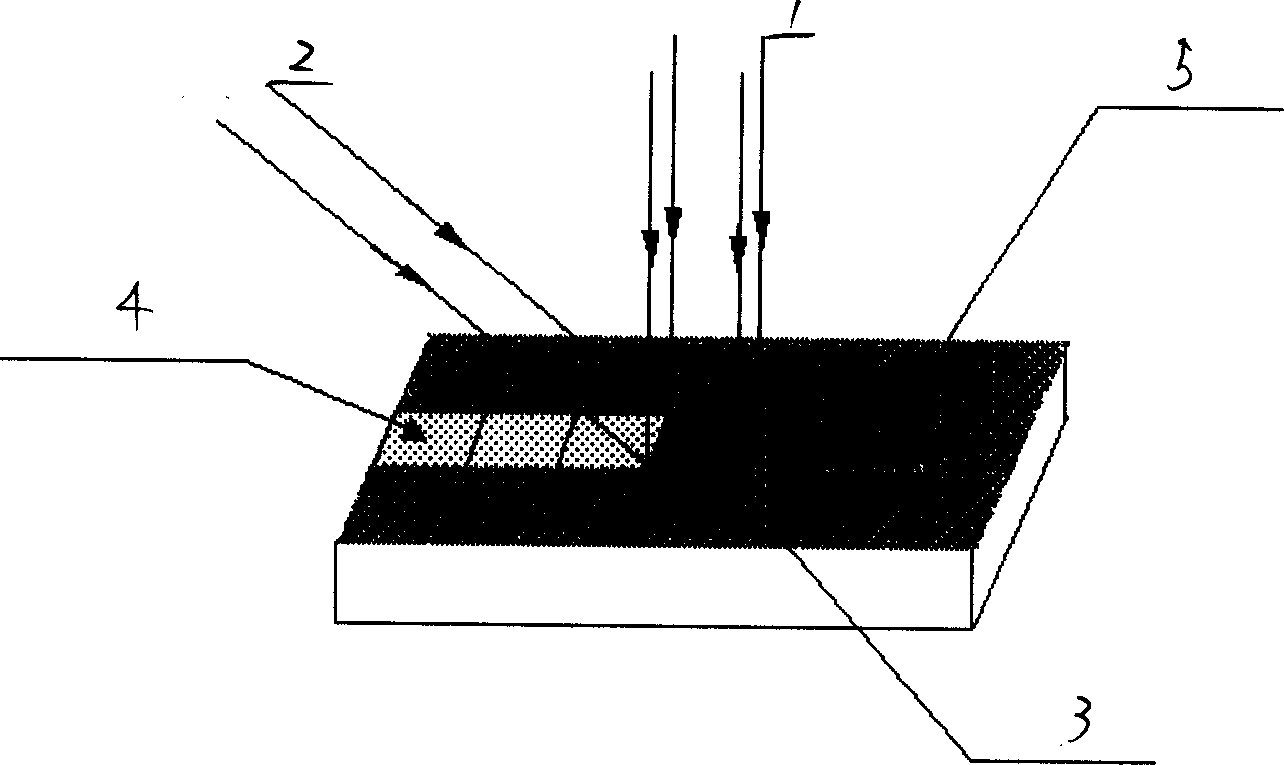

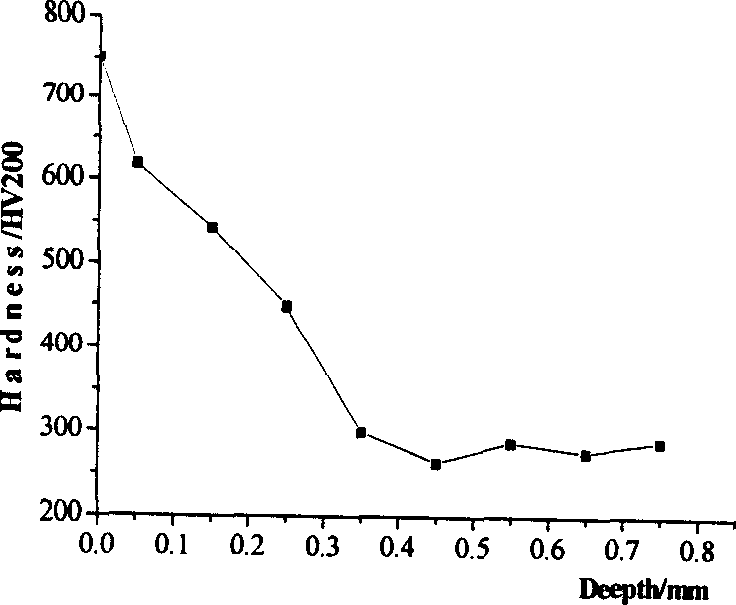

[0031] Refer to attached figure 1 , the nano-coating process on the metal surface includes the following steps: (1) sample pretreatment: cleaning the metal sample treatment part; (2) nanoparticle preparation: using chemical vapor deposition to prepare nickel-coated nano-alumina, nano-alumina particles It is spherical, with a diameter of 50nm, and the diameter of the particle after the surface is coated with nickel is about 150nm. The mass fraction of alumina in nickel-coated alumina powder is 30%; pre-coating: add a certain amount of binder to the mixed powder, stir and mix well to make a paste, and apply it on the surface with a brush 2Cr with dimensions 100×50×30mm 13 Stainless steel specimen surface. The preset coating thickness is 1mm; (3), according to the coating area, the laser beam 1 corresponding to the spot is selected for cladding treatment, and the laser process parameters are selected: the laser beam of the rectangular spot (10×2mm) is selected according to the ...

Embodiment 2

[0033] Embodiment two, refer to figure 1 , the nano-coating process on the metal surface includes the following steps: (1) sample pretreatment: cleaning the metal sample treatment part 1; (2) nanoparticle preparation: using chemical vapor deposition to prepare cobalt-coated nano-carbon tungsten, nano-carbon tungsten The particles are spherical, with a diameter of 50nm, and the diameter of the particles after the surface is coated with cobalt is about 150nm. The mass fraction of carbon tungsten in the cobalt-coated tungsten carbide powder is 30%; pre-coating 2: add a certain amount of binder to the mixed powder, stir and mix well to make a paste, and apply it with a brush 2Cr in size 100×50×30mm 13 Stainless steel specimen surface. The preset coating thickness is 1mm; (3), according to the coating area, select the beam corresponding to the spot for laser cladding treatment, the selection of the laser process parameters: select the laser beam of the rectangular spot (10×2mm) a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com