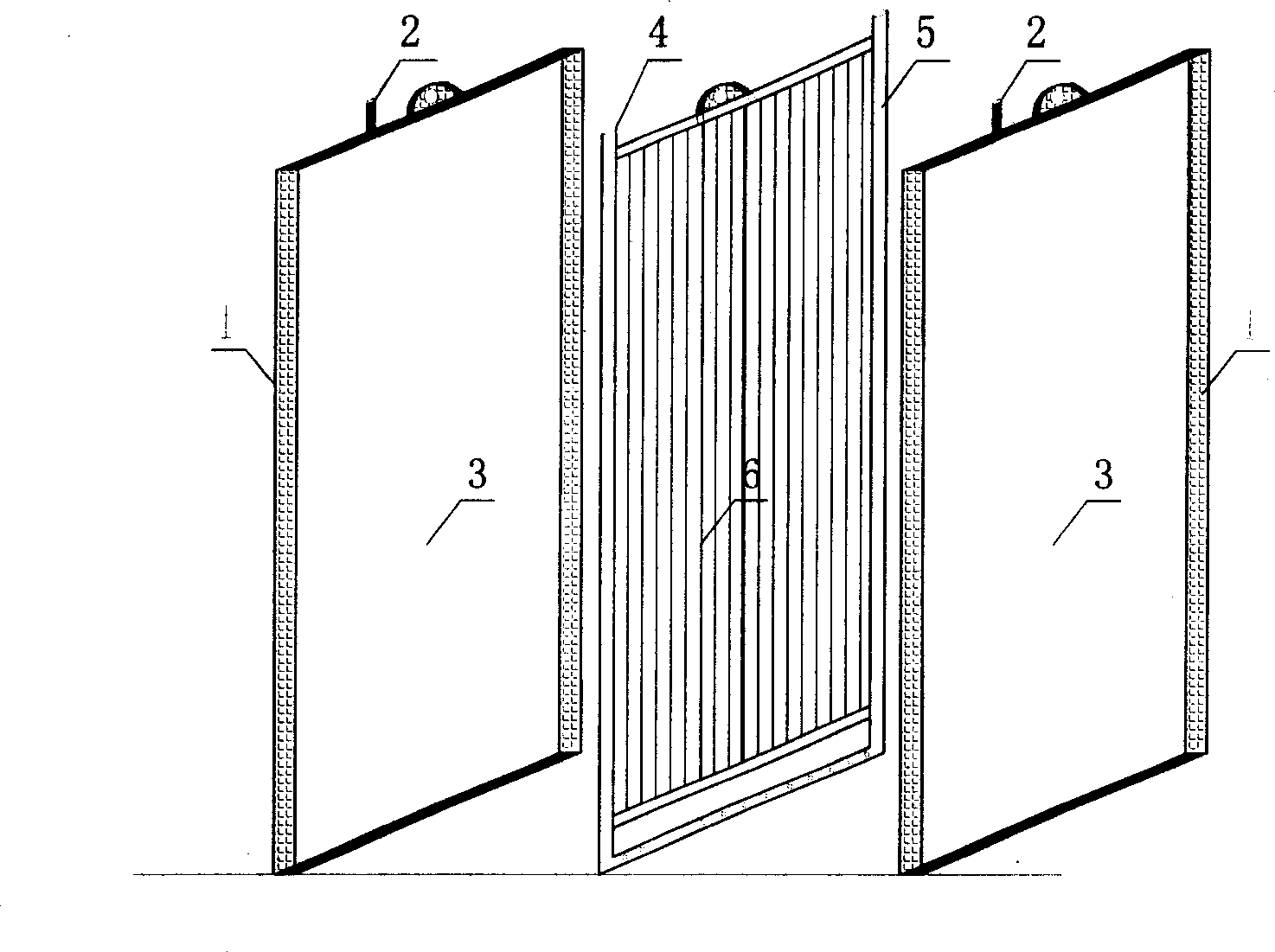

Combined membrance assembly

A membrane module and combined technology, which is used in the research and development and application of membrane separation technology, can solve the problems of accelerated pollution, dead angle, and increased energy consumption of membrane modules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] Will contain COD 200~500mg / L, BOD 5 100~300mg / L, ammonia nitrogen 50~160mg / L, SS 20~50mg / L domestic sewage enters the activated sludge membrane bioreactor for treatment. 0.4m 3 / hr, temperature 12~29℃, pH 6.5~8.0, stable operation for 6 months. The flat membrane flux in the new membrane module is stable at 40L / m 2 h, the flux of the hollow fiber membrane module is stable at 14L / m 2 h, the operating pressure is 18-22kpa, and the treatment effect is stable. The COD value of the system effluent varies between 10 and 30mg / L, and is generally stable below 20mg / L. 5 The value fluctuates between 1 and 3mg / L, the ammonia nitrogen is stable below 10mg / L, the SS is stable below 0.3mg / L, and the effluent water quality meets the "Urban Sewage Recycling-Urban Miscellaneous Water Quality" (GB / T18920-2002) standard .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com