Method for extracting small molecule collagen protein from fish scale utilizing enzyme engineering technique

A fish scale collagen and collagen technology, applied in the field of deep processing of fish scales, can solve the problems of amino acid loss and destruction, large molecular weight of fish scale collagen, complicated production process, etc., and achieve the effects of delaying aging, non-toxic effect and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

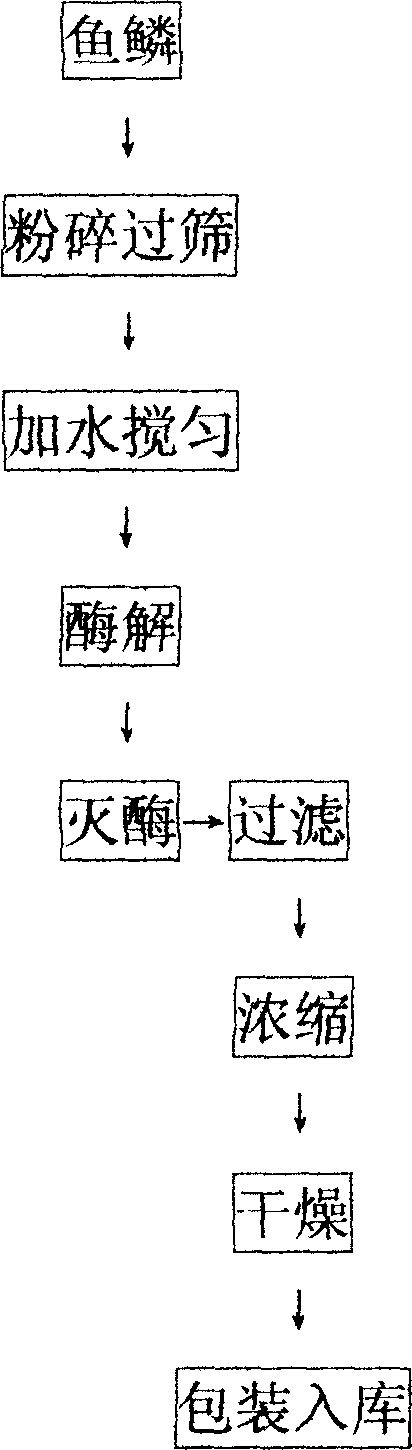

Image

Examples

Embodiment 1

[0023] Accurately weigh 1 kg of washed and dried fish scales, send them into a pulverizer for crushing, and pass through a 100-mesh standard sieve, add 8 kg of distilled water to the sieved fish scale powder, and stir evenly until the fish scale powder becomes a suspension . Heat the suspension to 35°C-70°C, add 10 grams of neutral protease under natural pH state for enzymolysis, the enzymolysis time is 5 hours, after the enzymolysis is complete, raise the temperature to 90°C and keep for 10 minutes to inactivate the enzyme. Then, the enzymolysis solution is filtered to obtain supernatant and filter residue, and the supernatant is concentrated and dried to obtain small molecule fish scale collagen.

Embodiment 2

[0025] Accurately weigh 2 kg of washed and dried fish scales, send them into a pulverizer for crushing, and pass through a 120-mesh standard sieve, add 20 kg of distilled water to the sieved fish scale powder, and stir evenly until the fish scale powder becomes a suspension . Heat the suspension to 35°C-70°C, adjust the pH to 8.0 with 10% lye, add 10 grams of alkaline protease for enzymolysis, and the enzymolysis time is 8 hours. Minutes to inactivate the enzyme, then filter the enzymolysis solution to obtain supernatant and filter residue, the supernatant is concentrated and dried to obtain small molecule fish scale collagen.

Embodiment 3

[0027] Accurately weigh 5 kg of washed and dried fish scales, send them into a pulverizer for crushing, and pass through a 120-mesh standard sieve, add 50 kg of distilled water to the sieved fish scale powder, and stir evenly until the fish scale powder becomes a suspension . Heat the suspension to 35°C-70°C, adjust the pH to 7.5 with 10% lye, add 10 grams of alkaline protease and 10 grams of papain at the same time for enzymolysis, the enzymolysis time is 4 hours, and the enzymolysis is complete. The temperature is raised to 90° C. and kept for 10 minutes to inactivate the enzyme, and then the enzymolysis solution is filtered to obtain a supernatant and filter residue, and the supernatant is concentrated and dried to obtain small molecule fish scale collagen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com