Quinone based compound, photosensitive article for electrophotography and electrophotographic device using the same

An electrophotographic and photoreceptor technology, applied in electroluminescence light sources, electric light sources, instruments, etc., can solve the problems of unstable ozone amount, adverse effects of photoreceptor use environment, etc., and achieve excellent electrical characteristics, excellent repeat stability, Excellent electrical properties and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0201] A sheet-shaped photoreceptor for testing electrical properties and a drum-shaped photoreceptor for testing printing performance were prepared, respectively. Incidentally, the term "part" means part by weight.

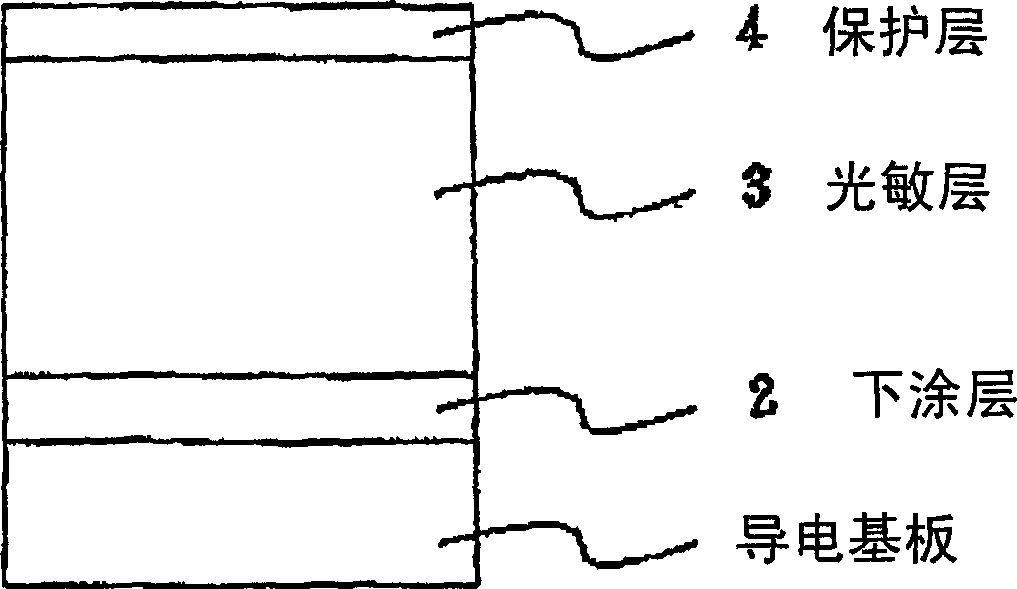

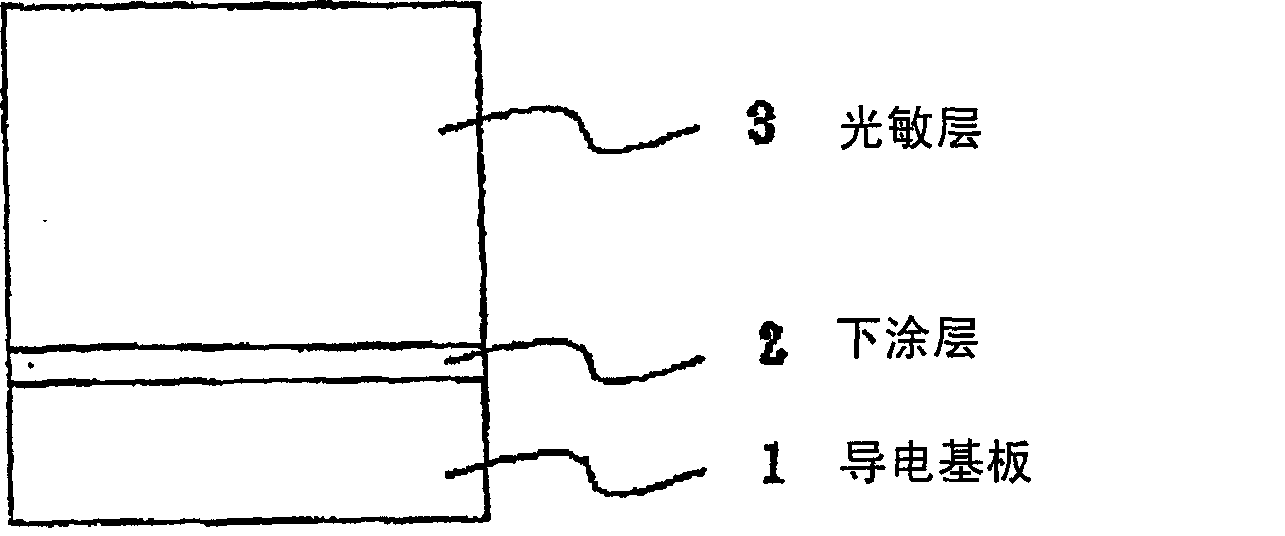

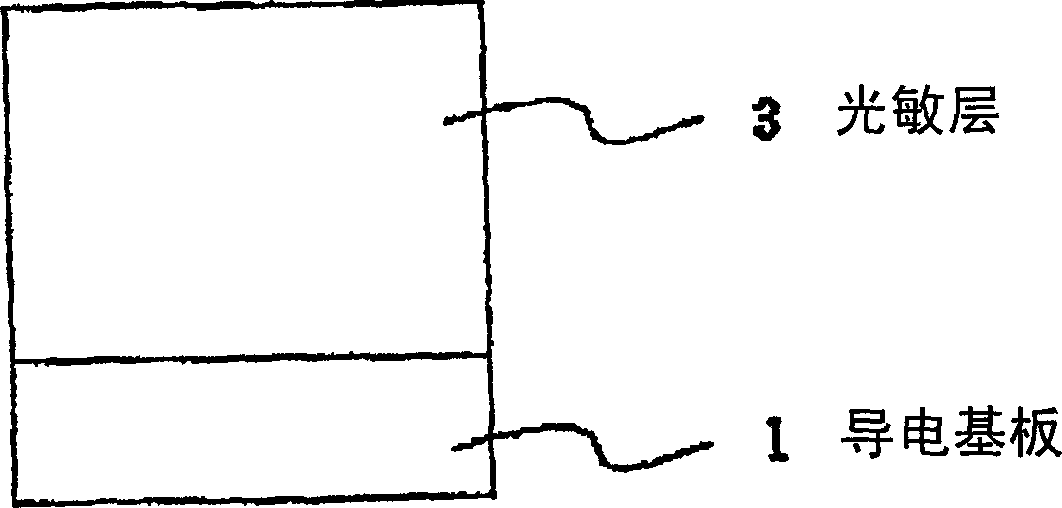

[0202] The solution for undercoating prepared in the following manner was applied to each aluminum sheet (3cm×10cm, thickness: 1mm) and aluminum drum (outer diameter: 30mmφ, length: 247.5mm, thickness: 0.75mm), and then dried at 100°C for 60 minutes to remove the solvent. Thus, an undercoat layer having a film thickness of 0.3 μm was formed.

[0203] (preparation of solution for undercoating)

[0204] a1) Soluble nylon (AMILAN CM8000, manufactured by Toray Industries, Inc.): 3 parts by weight (30 g)

[0205] The aforementioned material a1) for the undercoat layer was stirred with 97 parts by weight (970 g) of a mixed solvent of methanol / methylene chloride (5 vol / 5 vol), and dissolved to prepare a solution for the undercoat layer.

[0206] Next, on top of this...

Embodiment 2

[0217] Prepare photoreceptors in the same manner as photoreceptor Example 1, the difference is that, for the composition of the dispersion liquid for the single-layer photosensitive layer in photoreceptor embodiment 1, 5 parts by weight of the previous general formula (I- The compound represented by 3) was replaced by 5 parts by weight of the compound represented by the foregoing general formula (I-83) [Synthesis Example 2].

Embodiment 3

[0219] Prepare the photoreceptor in the same manner as photoreceptor Example 1, the difference is that, for the composition of the dispersion liquid used in the monolayer photosensitive layer in Photoreceptor Example 1, the styrene-based compound represented by the previous general formula (HT1-101) The material is changed into 7 parts by weight from 8 parts by weight; the amount of compound represented by the preceding general formula (I-3) as electron transfer material is changed from 5 parts to 2 parts: the amount of bisphenol Z type polycarbonate resin is changed from 7 parts to 10 servings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com