A kind of microbial electrode and preparation method thereof

A technology of microbial electrodes and electroactive microorganisms, applied in battery electrodes, biochemical fuel cells, circuits, etc., can solve the problems of unoptimized electricity generation performance, and achieve excellent electron transfer properties, high electroactivity, and improved electricity generation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

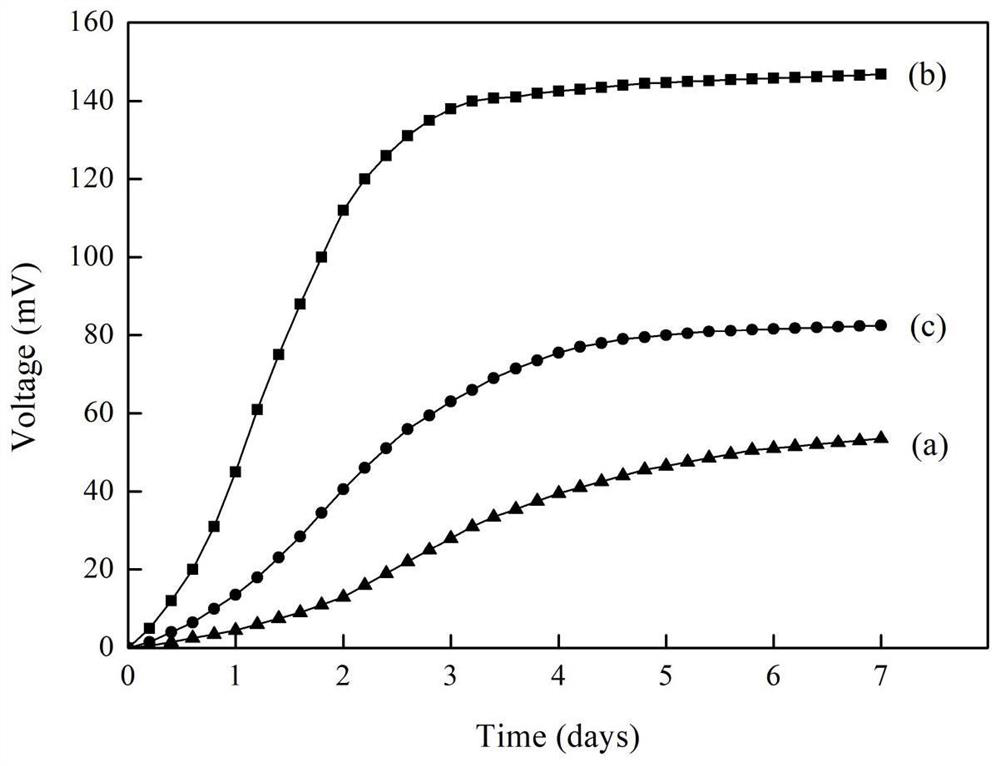

Embodiment 1

[0046] Use carbon felt as the electrode base material, cut it into a 3cm diameter disc, soak it in acetone solution overnight, fully wash it with deionized water, and dry it; after drying, soak the carbon felt in a concentrated nitric acid solution with a concentration of 60% by mass In the nitric acid reflux device, boil for 0.5h, wash with deionized water and ethanol alternately; put the acidified carbon felt in 0.005g / mL1-ethyl-3-(3-dimethylaminopropyl) carbon di imine (EDC) and 0.005g / mL N-hydroxysuccinimide (NHS) solution, stirred at room temperature for 0.5h, wherein the soaking ratio is 20-30mL solution per gram of substrate; add a certain amount of 3-aminophenylboronic acid to make The concentration is 0.01g / mL, continue to react for 10h, wash thoroughly with ultrapure water, and then dry in vacuum at 20°C for 10h; soak the carbon felt with phenylboronic acid fixed on the surface for 1h in 2g / L glucose solution, and fully wash with ultrapure water washing. The modifie...

Embodiment 2

[0048] Use carbon brush as the electrode base material, soak in acetone solution overnight, fully wash with deionized water, and dry; after drying, soak the carbon brush in a concentrated nitric acid solution with a concentration of 70% by mass, and boil it in a nitric acid reflux device 6h, wash with deionized water and ethanol alternately; put the acidified carbon brush into 0.04g / mL LEDC and 0.02g / mLNHS solution, stir at room temperature for 2h, add a certain amount of 3-aminophenylboronic acid to make the concentration 0.2g / mL mL, after continuing to react for 14 hours, fully wash with ultrapure water, and then vacuum-dry at 30°C for 14 hours; soak the carbon brush with phenylboronic acid fixed on the surface in 4g / L glucose solution for 1 hour, and fully wash with ultrapure water; the modified carbon brush The brush substrate material was co-cultured with the Shewanellaoneidensis MR-1 suspension, rotated at 1000 rpm, and incubated for 7 days to obtain an electrode material...

Embodiment 3

[0050] The carbon nanotubes were soaked in acetone solution overnight, fully washed with deionized water, collected by centrifugation, and then dried; the dried carbon nanotubes were soaked in a concentrated nitric acid solution with a concentration of 65% by mass, and boiled in a nitric acid reflux device for 30 minutes After being collected by centrifugation, alternately wash with deionized water and ethanol, and centrifuge; put the acidified carbon nanotubes into 0.02g / mL LEDC and 0.01g / mLNHS solution, stir at room temperature for 1h, add a certain amount of 3-aminophenylboronic acid to make it Concentration is 0.1g / mL, continue to react for 12h, then collect by centrifugation, wash thoroughly with ultrapure water, and then dry in vacuum at 25°C for 12h; carbon nanotubes with phenylboronic acid immobilized on the surface are soaked in 8g / L glucose solution for 1h, and ultrapure Fully washed with water; the modified carbon nanotubes were co-cultured with G. sulfurreducens (AT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com