Oxygen-hydrogen heating method and system for soldering iron

A heating method and soldering iron technology, which is applied in the hydrogen-oxygen heating of soldering iron and its system field, can solve the problems of inconvenient use, environmental pollution, poor safety, etc., and achieve a wide range of applicable places, a wide adjustable temperature range, and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings:

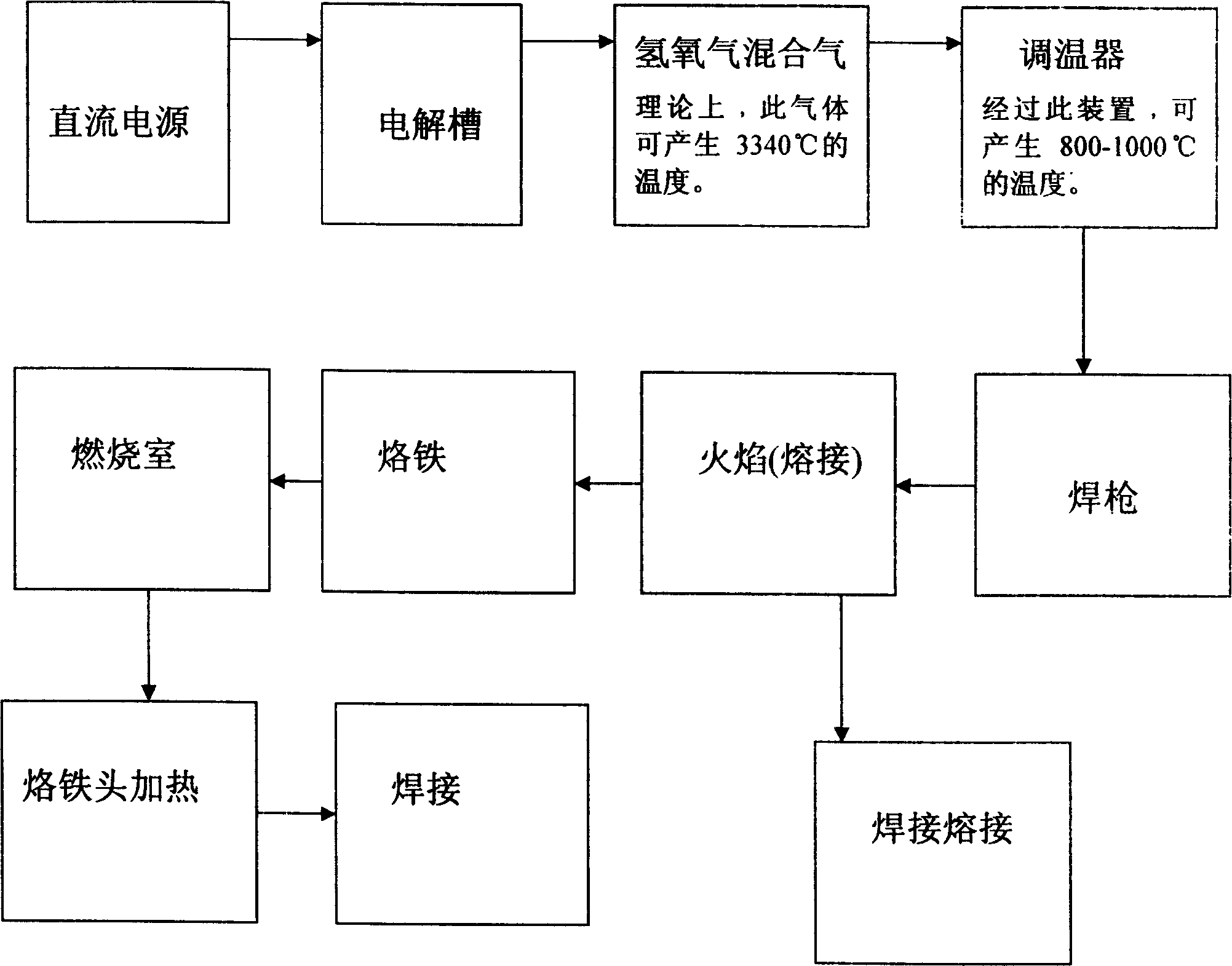

[0033] working principle

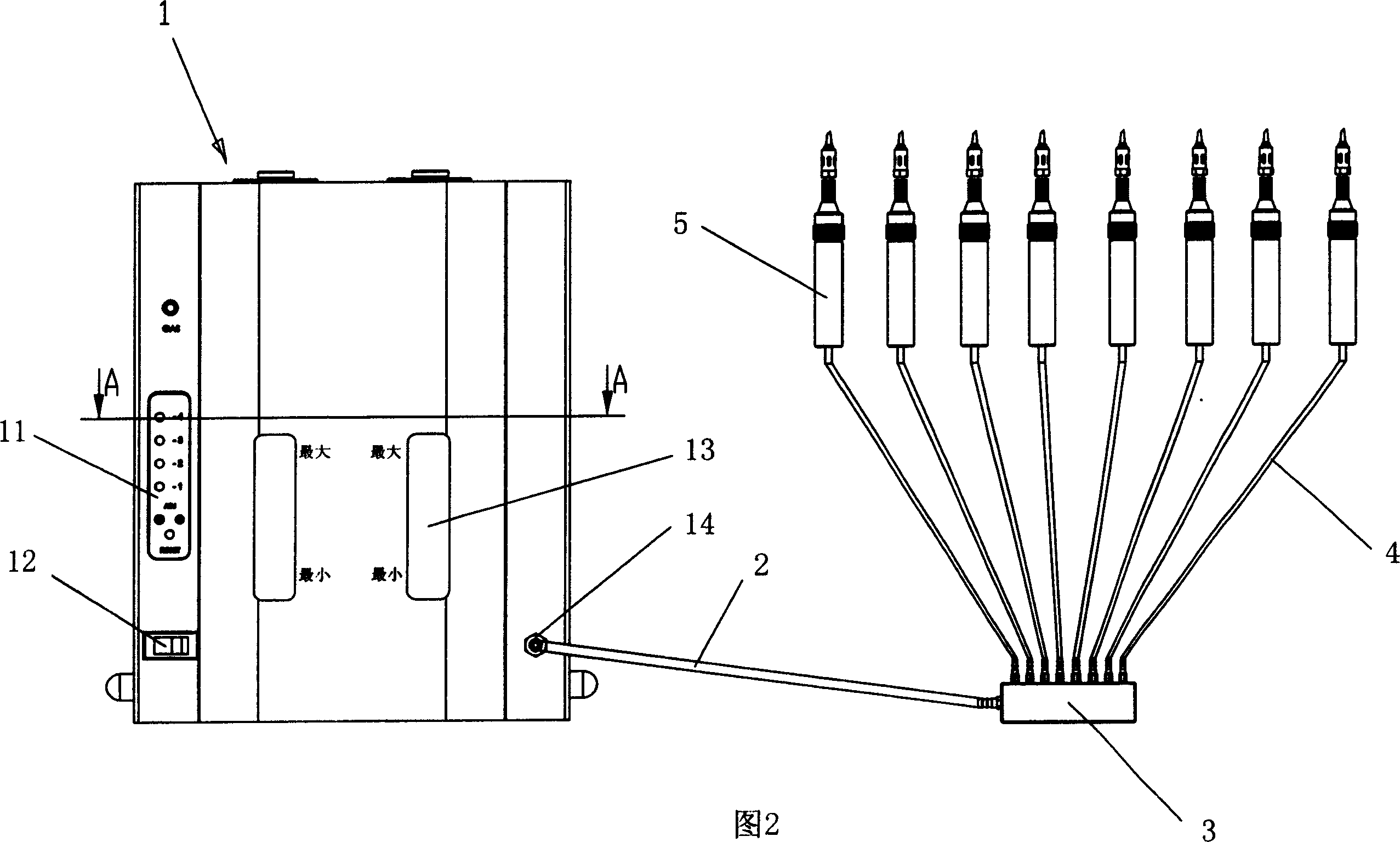

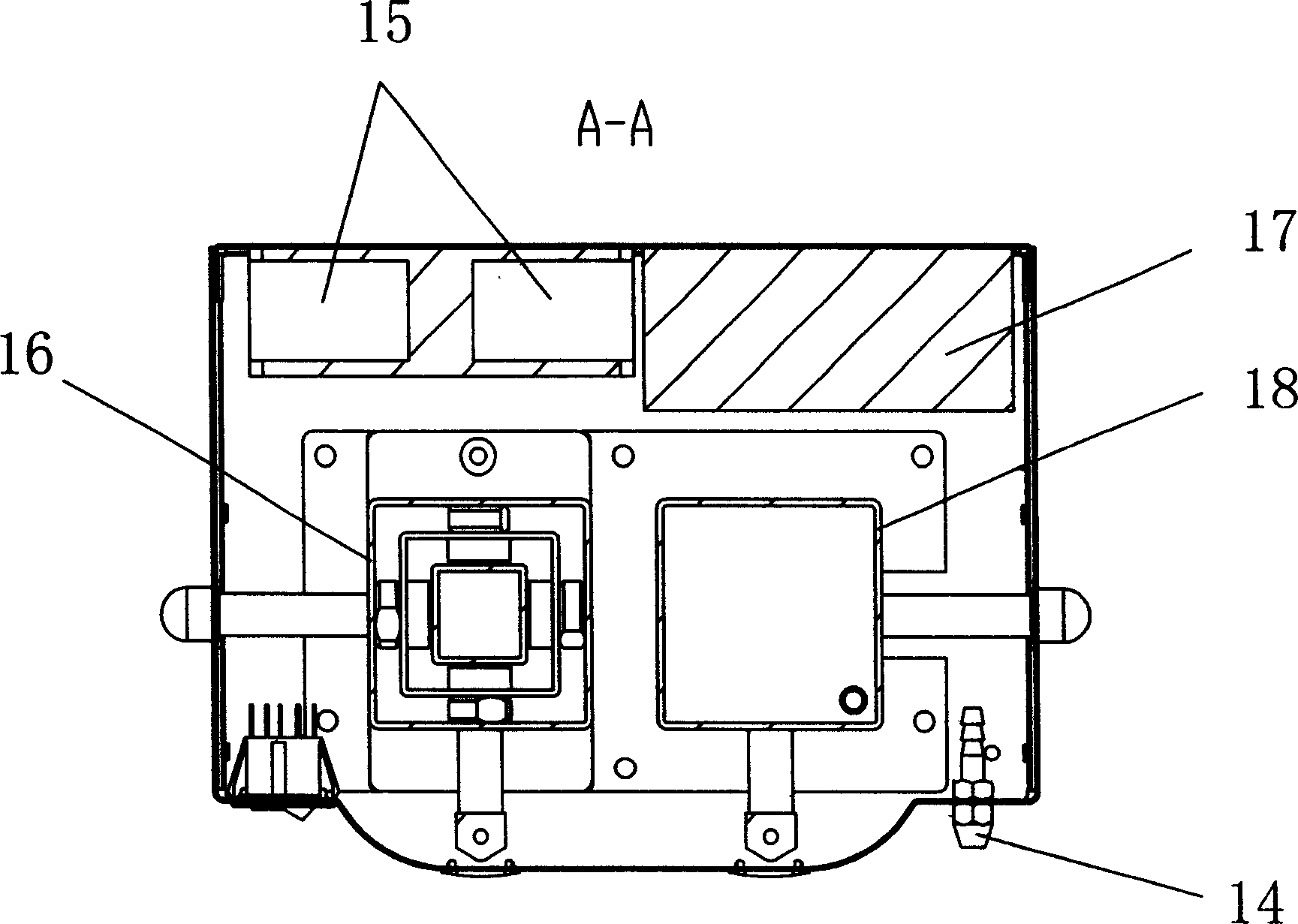

[0034] Add 500ml of 25% alkali (KOH) solution to the electrolytic cell 16 of the hydrogen-oxygen generator 1 (only water will be added later), and after electrolysis by the switching power supply 17, hydrogen-oxygen (H2, O2) gas is generated, and the H2, O2 gas enters the mixing Tank 18, the hydrocarbons (acetone CH3COCH3 liquid or oil solvent for removing stains) contained in the mixing tank 18, the H2 and O2 gases passing through the mixing tank 18 will be mixed into the hydrocarbons (CH3COCH3 gas), so that the composition of the mixed gas is H2 , O2, hydrocarbons (CH3COCH3), adding hydrocarbons (acetone) gas to oxyhydrogen gas is to reduce the concentration of oxyhydrogen in order to reduce the combustion temperature. The mixed gas is led out of the hydrogen-oxygen generator 1 by an 8mm gas delivery pipe 2, and the gas from the hydrogen-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com