Catalyzing synthesis of citric tributyl ester from carbon-base sulfoacid

A technology of tributyl citrate and carbon-based sulfonic acid is applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid esters, etc. The effect of mild conditions, small amount of catalyst, and cheap catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

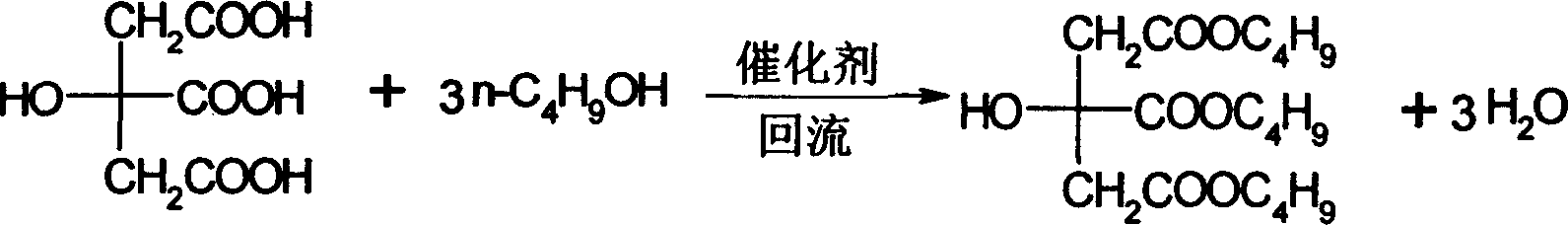

Image

Examples

Embodiment 1

[0018] Preparation of the first step carbonyl sulfonic acid

[0019] Add 10ml of concentrated sulfuric acid to 15g of cracked C9 fraction, heat and react at 250°C for 4h, then add boiling water to reflux and stir for 3h, filter with suction, and dry at 140°C to obtain carbonylsulfonic acid;

[0020] Step 2 Esterification Reaction

[0021] Add 0.1 mol of citric acid, 0.45 mol of n-butanol and 0.3 g of carbonyl sulfonic acid into a 100 mL three-neck flask equipped with electromagnetic stirring, thermometer, reflux condenser, and water separator, heat and reflux and stir to make the water produced by the reaction Separated from the water separator, reacted until there was no water, then entered the water separator to stop, and obtained the crude product of tributyl citrate and took a sample to measure the acidity. The acid value was determined in accordance with GB / T1668-1995;

[0022] Step 3 Separation of catalyst and purification of product

[0023] Filter the crude product, ...

Embodiment 2-4

[0025] Except following difference, all the other are identical with embodiment 1, be 0.3g in the carbon base sulfonic acid consumption, be 0.1mol in the citric acid consumption, see table 1 on the impact result of n-butanol consumption on reaction.

[0026] Example

Embodiment 5-8

[0028] Except following difference, all the other are identical with embodiment 1, and the impact result of carbon base sulfonic acid consumption is shown in Table 2

[0029] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com