Chemical gas-phase deposition for producing diamond thin filmon cutter with complex-formation

A chemical vapor deposition, diamond thin film technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, to achieve the effect of improving film growth rate, uniform distance, and increasing nucleation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 Carbide drill bit

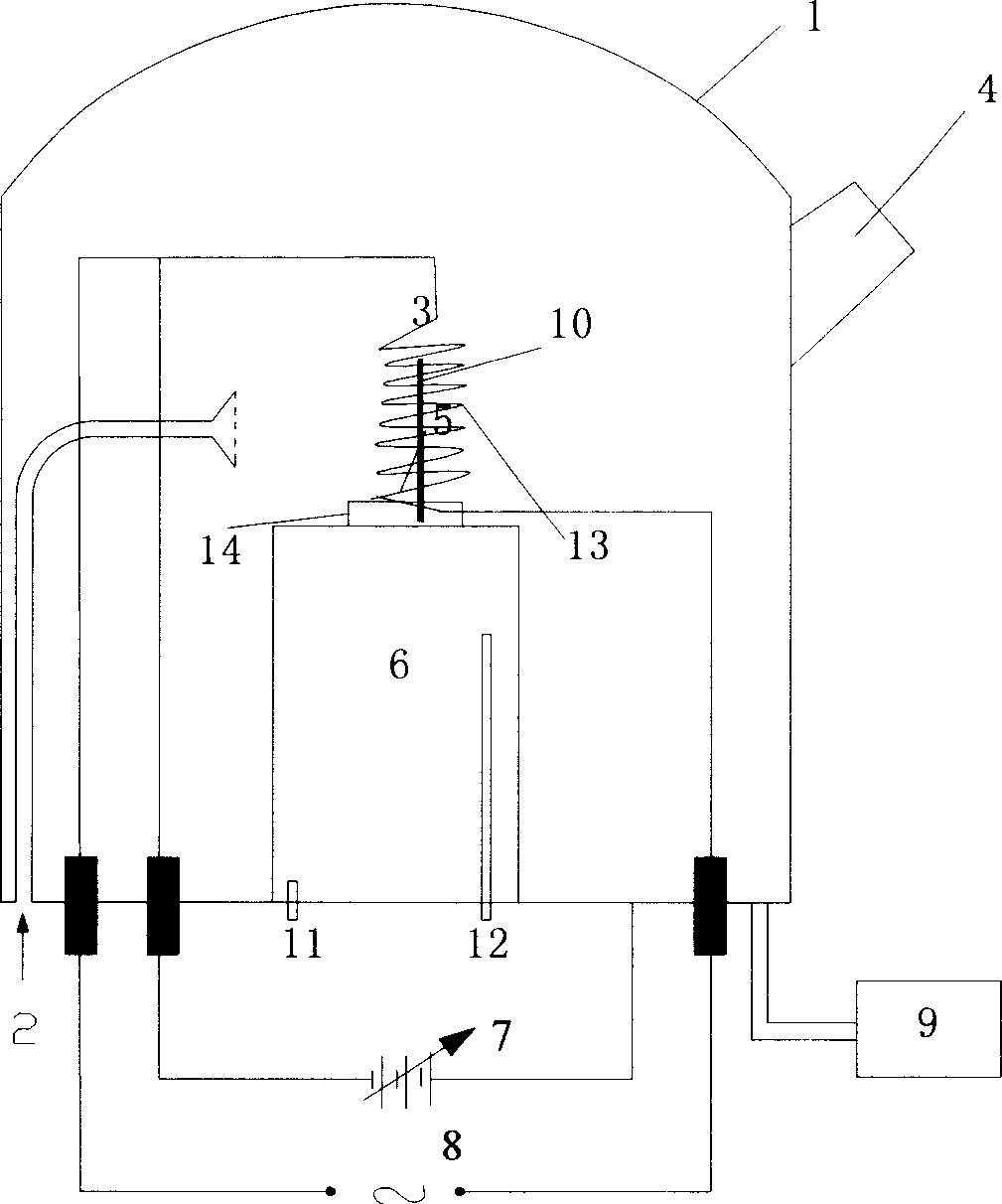

[0019] A diamond film with high uniformity was prepared with a cemented carbide drill as a substrate. The sample adopts high-precision hard alloy drill bit YG6 (WC-Co6%) (Φ3mm). The sample is Murakami solution (K 3 [Fe(CN) 6 ]:KOH:H 2 O=1:1:10) ultrasonic cleaning for 20 minutes, and then in the etching solution (H 2 SO 4 :H 2 o 2 =7:3) for 10s, then ultrasonically cleaned with acetone and coated with adhesion promoter and dried. Such as figure 1 As shown, the heating wire adopts a helical heating wire structure. The helical diameter of the helical heating wire mechanism is 9 mm, the pitch is 1 mm, and the height is 50 mm, which can just cover the required growth range. The spiral heating wire structure is placed vertically in the reaction chamber, the upper and lower brackets support the heating wire, and the upper and lower brackets are connected to the power supply. Place the pre-treated drill bit in the middle of the hot wi...

Embodiment 2

[0021]Embodiment 2 Hard alloy milling cutter

[0022] A diamond film with high uniformity was prepared with a cemented carbide milling cutter as a substrate. The sample adopts high-precision hard alloy milling cutter YG6 (WC-Co6%) (Φ2mm). The sample is Murakami solution (K 3 [Fe(CN) 6 ]:KOH:H 2 O=1:1:10) ultrasonic cleaning for 20 minutes, and then in the etching solution (H 2 SO 4 :H 2 o 2 =7:3) for 10s, then ultrasonically cleaned with acetone and coated with adhesion promoter and dried. Such as figure 1 As shown, the heating wire adopts a helical heating wire structure. The helical diameter of the helical heating wire mechanism is 8mm, the pitch is 1mm, and the height is 30mm, which can completely cover the required growth range. The spiral heating wire structure is placed vertically in the reaction chamber, the upper and lower brackets support the heating wire, and the upper and lower brackets are connected to the power supply. Place the pre-treated drill bit in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com