Production and producer for cadmium sulfide

A production process and production equipment technology, applied in the production process and equipment field of cadmium sulfide thin film, can solve the problems of unsatisfactory film uniformity and compactness, difficult to control the reaction process, complicated electrodeposition process, etc., and the reaction speed is easy to achieve Control, easy control of process parameters, rich source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

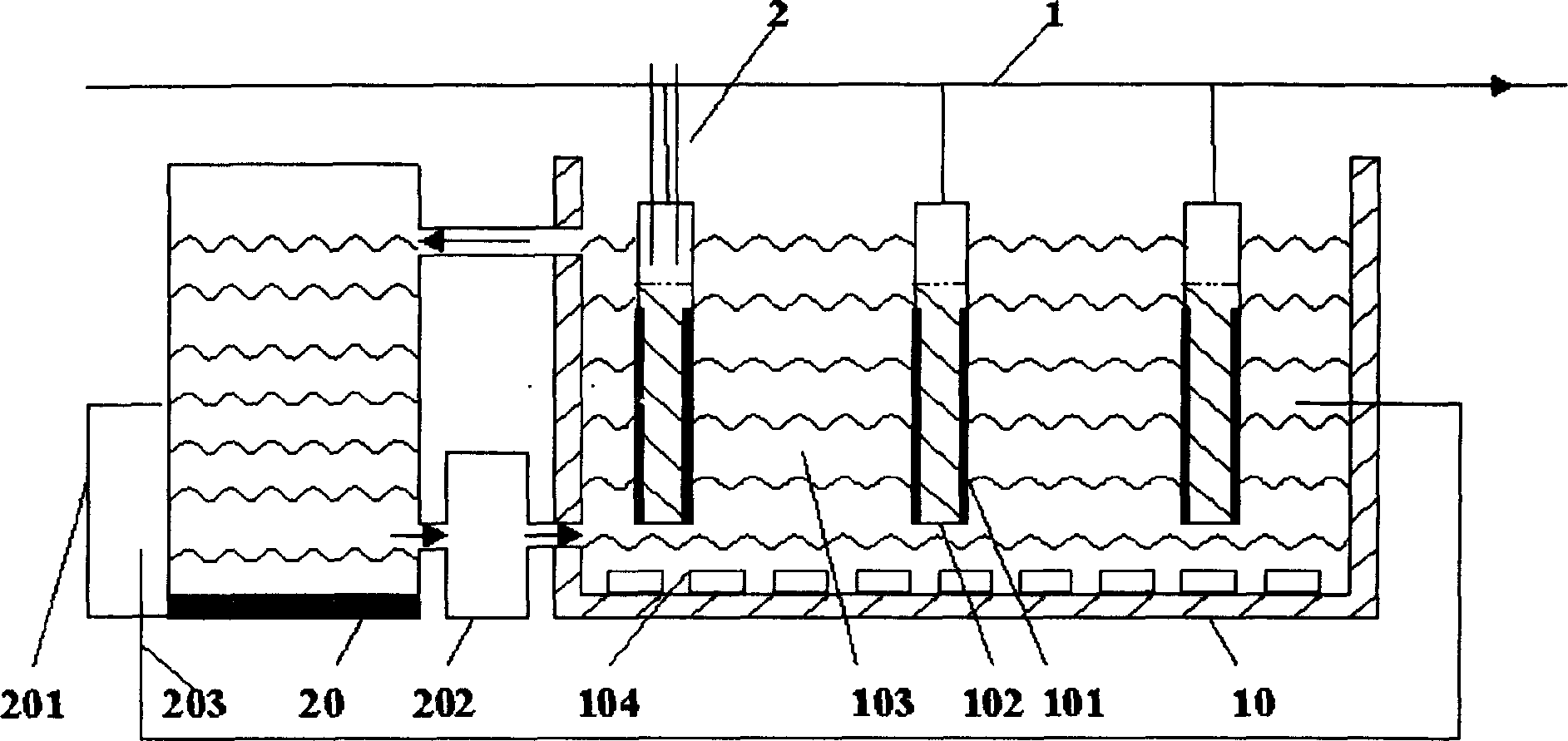

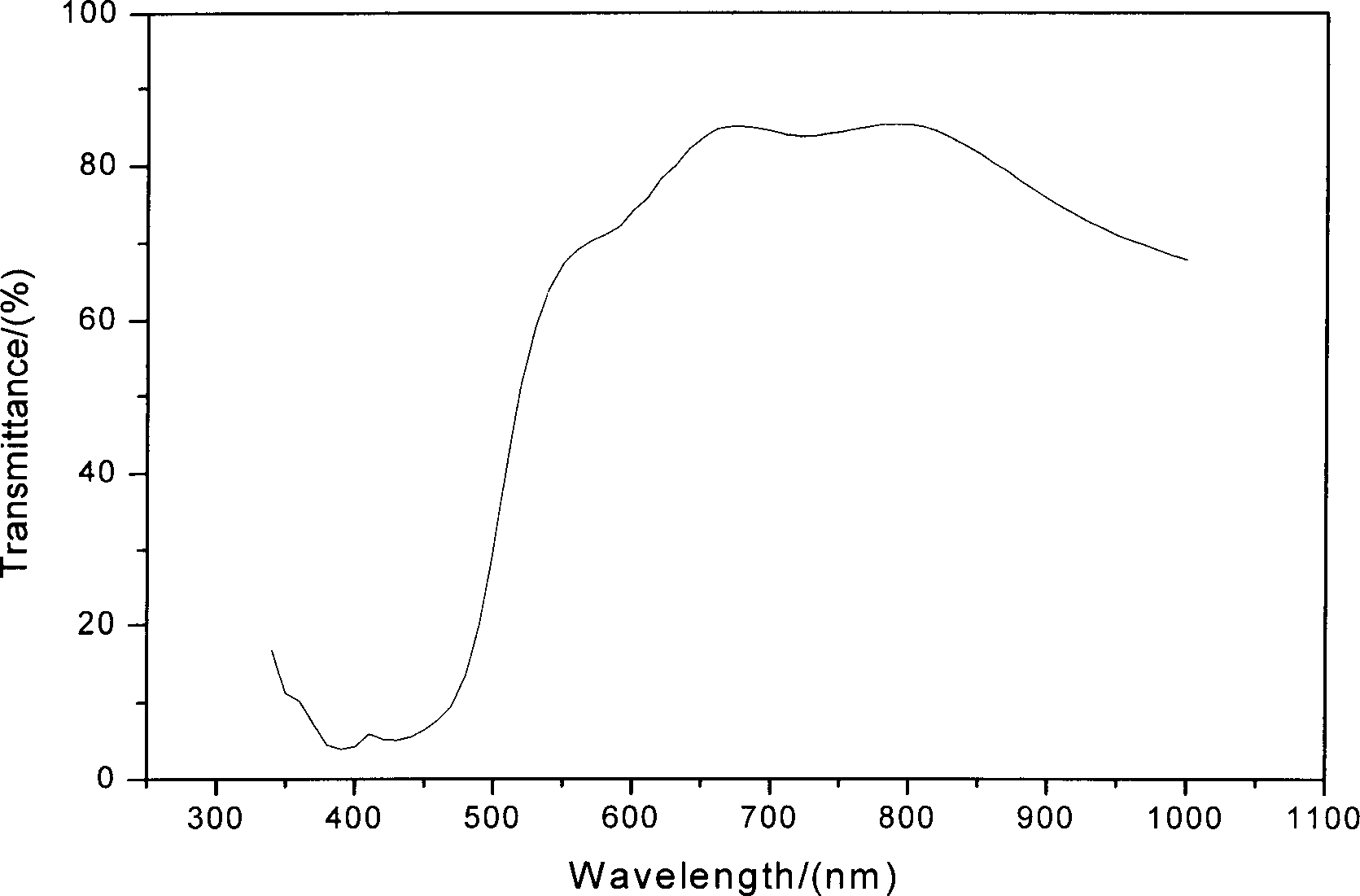

[0024] (1) Select FTO glass as the substrate 101, ultrasonically clean with acetone for 5 minutes, methanol for 5 minutes, deionized water for 5 minutes, dry, then put it into the reactor 102 and close to the wall; ( 2) Dissolve the weighed cadmium dichloride, ammonium chloride, thiourea, and ammonia water in high-purity water, and the prepared solution concentrations are respectively: cadmium dichloride 0.006mol / L, ammonium chloride 0.002mol / L, sulfur Urea 0.15mol / L, ammonia 0.4mol / L, filter; inject it in the reactor 102 through the solution injection port of the conveyor belt 1, to submerge the top of the substrate 101; (3) place the reactor 102 in the thermostatic chamber 10, Send hot water (i.e. heat medium solution) through the booster pump 202 and keep the water temperature constant at 85 ° C, introduce 40 kHz ultrasonic waves, and react for 20 minutes; (4) After the reaction is completed, pour out the reaction solution and add the same temperature The distilled water wa...

Embodiment 2

[0027] (1) Select ITO glass as the substrate 101, ultrasonically clean with acetone for 4 minutes, methanol ultrasonically for 6 minutes, deionized water for ultrasonically for 5 minutes, dry, then put it into the reactor 102 and close to the wall; ( 2) Dissolve the weighed cadmium dichloride, ammonium chloride, thiourea, and ammonia water in high-purity water, and the prepared solution concentrations are respectively: cadmium dichloride 0.005mol / L, ammonium chloride 0.002mol / L, sulfur Urea 0.10mol / L, ammonia water 0.3mol / L, filter; (3) keep the water temperature constant at 80°C with hot water, introduce 50 kHz ultrasonic waves, and react for 15 minutes; (4) After the reaction is completed, pour out the reaction solution, Add distilled water at the same temperature to shake and clean for 4 minutes, then pour out the cleaning solution, then add 3wt% ammonium nitrate solution at the same temperature, ultrasonically clean for 5 minutes, pull out the rough particles on the surface...

Embodiment 3

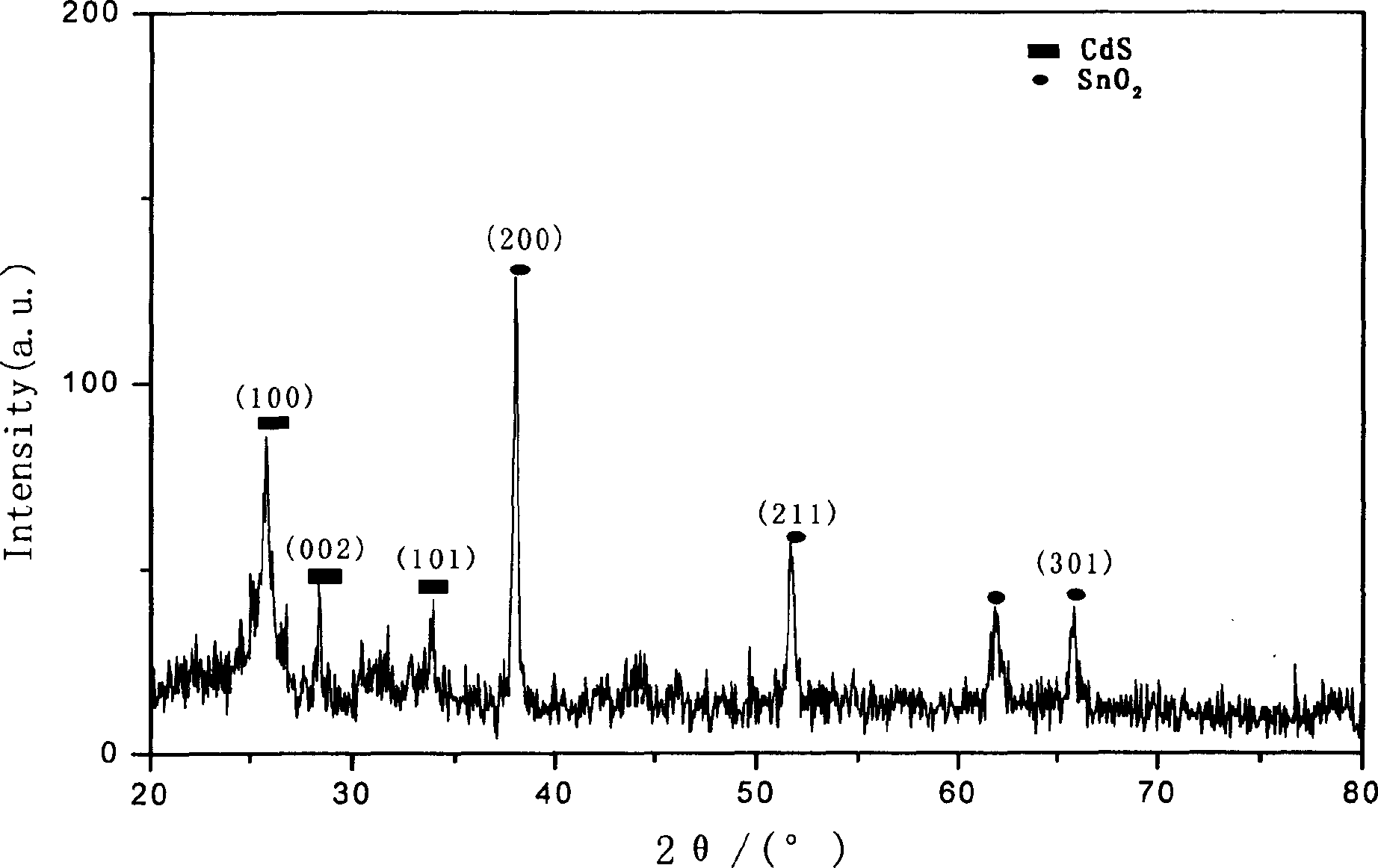

[0030] (1) Select SnO plating 2 Glass is used as the substrate 101, which is ultrasonically cleaned with acetone for 6 minutes, methanol for 4 minutes, deionized water for 6 minutes, dried, and then put into the reactor 102 and close to the wall of the device; (2) weigh Dissolve cadmium dichloride, ammonium chloride, thiourea, and ammonia water in high-purity water, and the concentrations of the prepared solutions are: cadmium dichloride 0.007mol / L, ammonium chloride 0.002mol / L, and thiourea 0.20mol / L , ammonia 0.4mol / L, filtered; (3) hot water to keep the water temperature constant at 90°C, introduce 55 kHz ultrasonic waves, and react for 25 minutes. Others are the same as embodiment 1.

[0031] The cadmium sulfide film prepared in this example has a wurtzite (hexagonal) crystal structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com