Method for synthesizing tin-titanium carbide at low temperature

A technology of tin carbide, titanium, and low temperature, which is applied in chemical instruments and methods, inorganic chemistry, tin compounds, etc., can solve the problems of long synthesis time, high sintering temperature, and influence on the large-scale production of powder, and achieve short ball milling time and synthetic powder The effect of low cost and shortened synthesis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0017] According to the ratio of ball to material of 20:1, graphite C powder is put into the ball mill jar, the ball mill jar is evacuated, and the vacuum degree is less than 1Pa; the speed of the planetary high-energy ball mill is 300r / min, and the grinding ball is agate ball; 4h of ball milling to obtain ultrafine C powder. Then press Ti:Sn:C=2:1:1 molar ratio batching, take by weighing 42.3 grams of Ti powder, 52.5 grams of Sn powder, 5.3 grams of superfine C powder, put into plastic bottle, take agate ball as grinding medium, Mix on the mixer for 5h. The mixed material is pressed into a block under a pressure of 50MPa. Put the briquette into a high-temperature furnace, in an argon atmosphere, raise the temperature of the furnace to 650°C at a heating rate of 40°C / min, and hold the temperature for 30 minutes to obtain Ti 2 SnC powder.

Embodiment approach 2

[0019] According to the ratio of ball to material of 50:1, graphite C powder is put into the ball mill jar, the ball mill jar is evacuated, and the vacuum degree is less than 1Pa; the speed of planetary high-energy ball mill is 250r / min, and the grinding ball is agate ball; After 6h of ball milling, ultrafine C powder was obtained. According to the molar ratio of Ti: Sn: C=2:0.95:0.95, weigh 43.6 grams of Ti powder, 51.3 grams of Sn powder, and 5.2 grams of superfine C powder, put them into plastic bottles, and use agate balls as grinding media. Mix in a ball mill for 8 hours. The mixed material is pressed into a block under a pressure of 80MPa. Put the briquette into a high-temperature furnace in a vacuum atmosphere, raise the temperature of the furnace to 550°C at a heating rate of 10°C / min, and hold the temperature for 5 minutes to obtain Ti 2 SnC powder.

Embodiment approach 3

[0021] According to the ratio of ball to material of 80:1, graphite C powder is put into the ball mill jar, and the ball mill jar is evacuated, and the vacuum degree is less than 1Pa; the speed of planetary high-energy ball mill is 180r / min, and the grinding ball is agate ball; 11h of ball milling to obtain ultrafine C powder. According to the molar ratio of Ti: Sn: C=2:0.8:0.8, weigh 48.1 grams of Ti powder, 47.7 grams of Sn powder, and 4.2 grams of superfine C powder, put them into plastic bottles, and use agate balls as grinding media. Mix in a ball mill for 10 hours. The mixed material is pressed into a block under a pressure of 100 MPa. Put the briquette into a high-temperature furnace, and in a vacuum atmosphere, raise the temperature of the furnace to 800°C at a heating rate of 20°C / min, and hold the temperature for 15 minutes to obtain Ti 2 SnC powder.

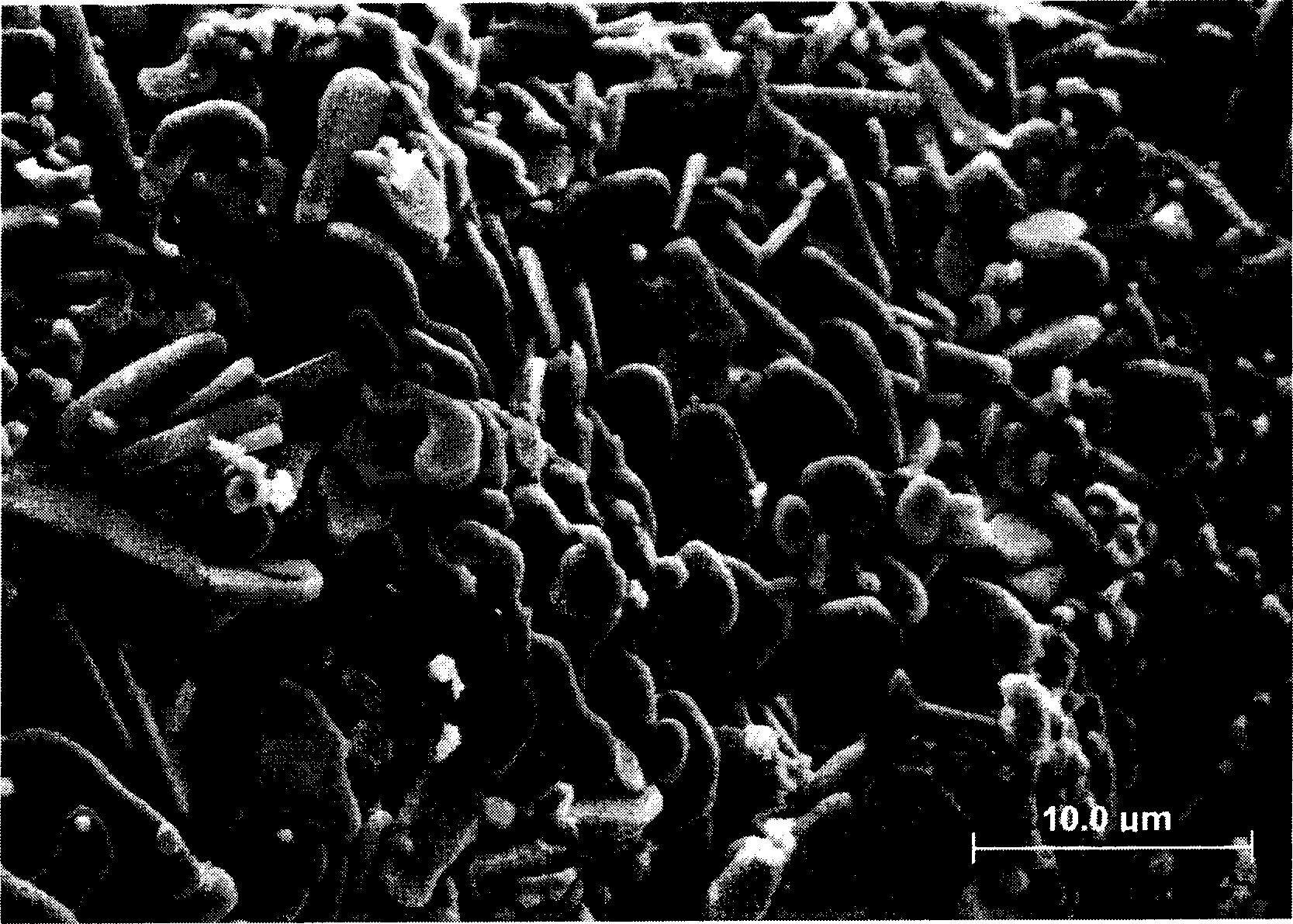

[0022] Ti synthesized by the present invention 2 SnC powder morphology see attached figure 1 . Ti 2 The surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com