Optical sensor for thin film detection

An optical sensor and thin-film technology, applied in the field of optics, can solve problems such as inability to detect stress and growth rate in local areas of thin films, and high requirements for daily debugging and maintenance of optical systems, so as to enhance scientificity and accuracy, improve quality and output, Realize the effect of industrial scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below with reference to the accompanying drawings.

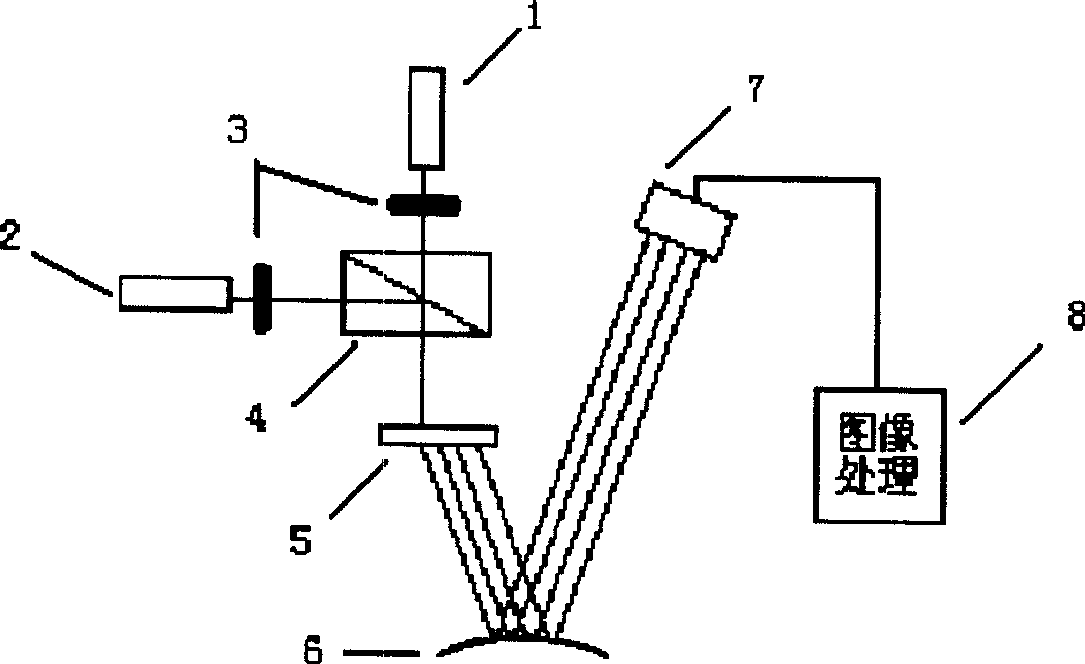

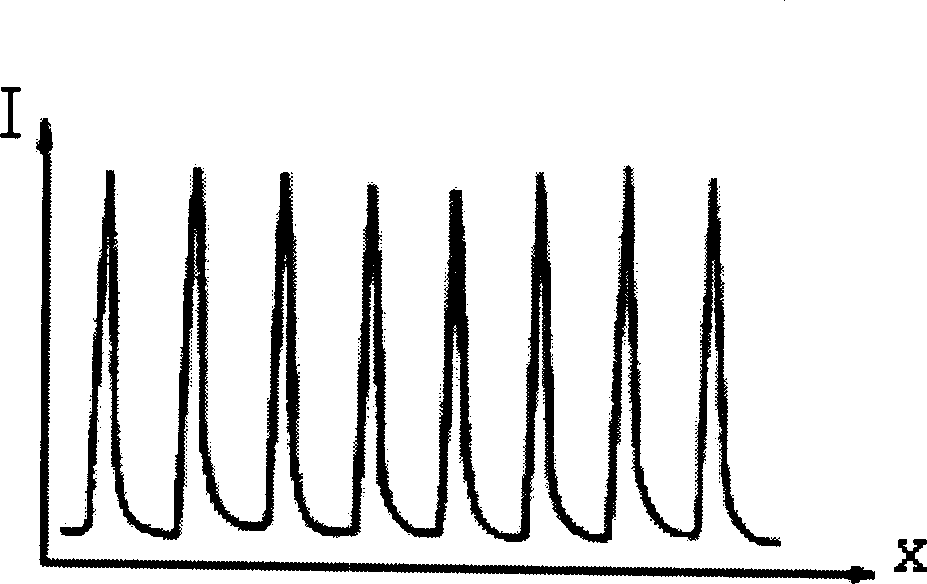

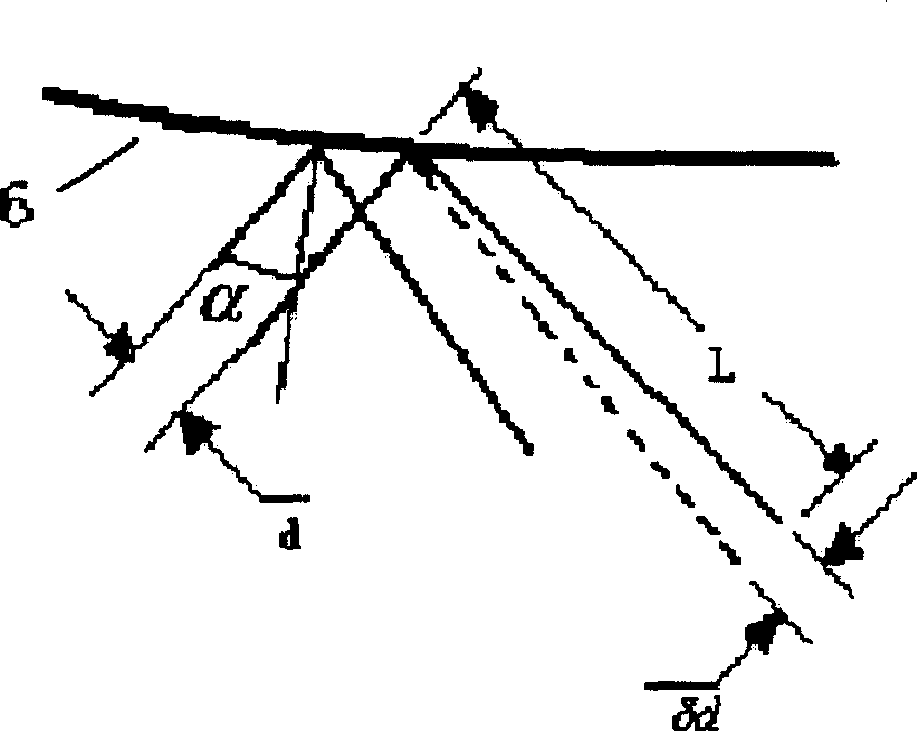

[0031] refer to figure 1 , the optical sensor of the present invention is composed of a first laser 1 , a second laser 2 , a controllable chopper 3 , a beam splitting prism 4 and a binary beam splitter 5 . The chopper (3) is controlled by an external circuit, so that the two laser beams of different frequencies output by the first pumping diode laser (1) and the second pumping diode laser (2) alternately pass through the chopper, and finally only Output a beam of laser light into the beam splitting prism (4). The binary grating beam splitter (5) is composed of a two-dimensional Dammann grating and a Fresnel zone plate, and is used to generate a self-converging multi-beam array. The present invention adopts the structure of two-color light incident and controllable optical chopper, can obtain Figure 4 The reflectance variation curve of light at two different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com