Preparation method of carbon clocd ferrolithium phosphate of lithium ion battery anode material

A carbon-coated technology for lithium ferrous phosphate and lithium ion batteries, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of poor conductivity, complex process, high cost, and achieve high current discharge capacity improvement, equipment And the effect of simple operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

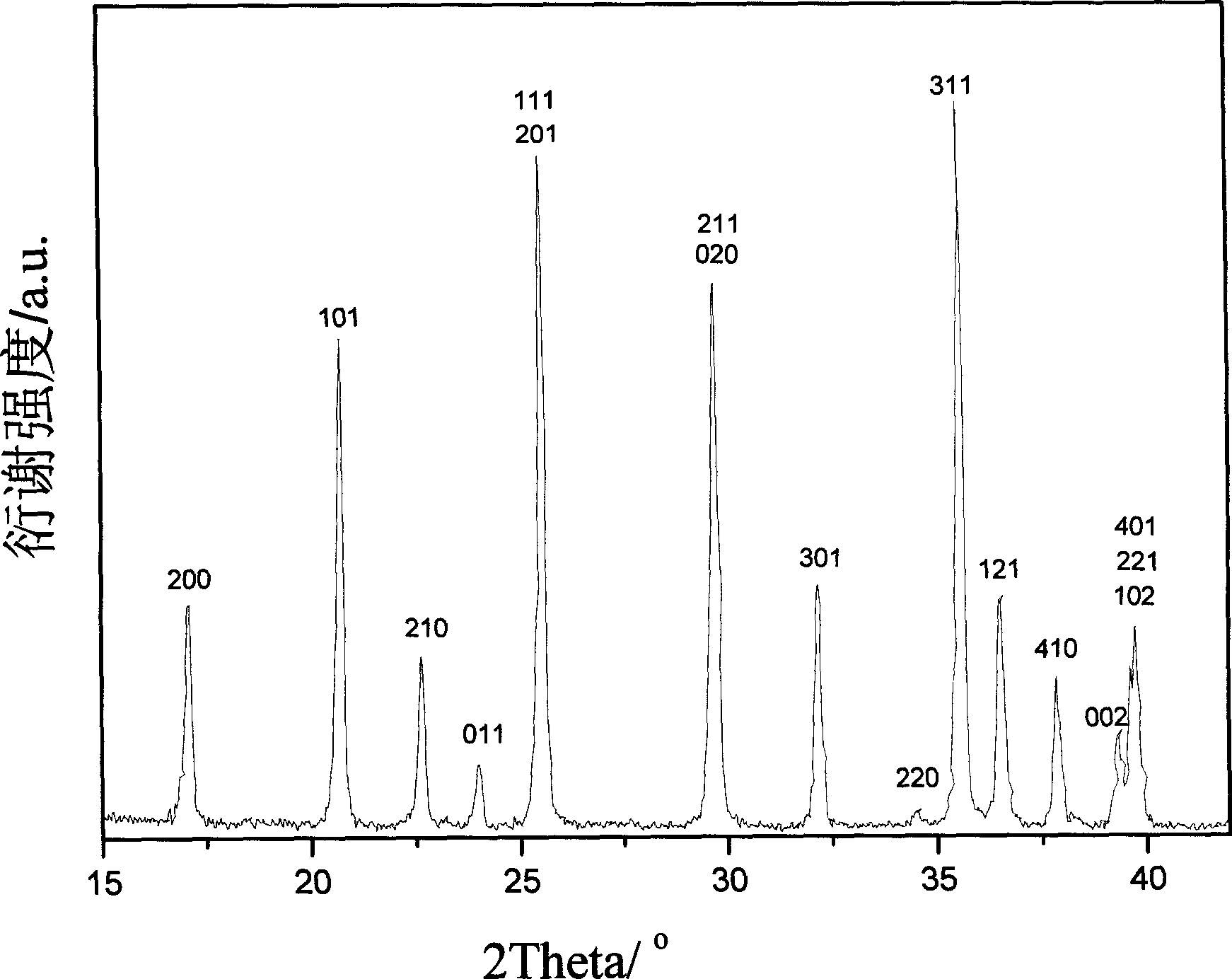

[0023] 0.97 moles of Li(OH).H 2 O, 0.5 mol Fe 2 o 3 , 1 mole NH 4 h 2 PO 4 , 0.004 mol Nb 2 o 5 , plus 40 grams of polypropylene, ball milled for 4 hours, placed in a furnace and heated to 650°C under nitrogen protection, kept at a constant temperature for 10 hours, cooled naturally and then ground again to obtain a niobium-doped and carbon-coated lithium iron phosphate composite material (LiFePO 4 / C). figure 1 It is the XRD spectrum of the material, where (200), (101), (210), (111), (201), (211), (020), (301), (311), (121) and other diffraction peaks for LiFePO 4 characteristic peaks of the material. figure 2 SEM photograph of the material.

Embodiment 2

[0025] 0.90 mol Li(OH)·H 2 O, 1 mole of FePO 4 , 0.01 mol Nb 2 o 5 , plus 40 grams of polypropylene, ball milled for 10 hours, placed in a furnace and heated to 600°C under nitrogen protection, kept at a constant temperature for 20 hours, cooled naturally and then ground again to obtain a niobium-doped and carbon-coated lithium iron phosphate composite material (LiFePO 4 / C).

Embodiment 3

[0027] 0.49 mol Li 2 CO 3 , 1 mol FePO 4 , 0.0025 mol Nb 2 o 5 , plus 30 grams of carbon black, ball milled for 10 hours, placed in a furnace, heated to 700°C under the protection of nitrogen and kept at a constant temperature for 6 hours, then ground again after natural cooling to obtain a niobium-doped and carbon-coated lithium iron phosphate composite material (LiFePO 4 / C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com