Non-inflammable light joist capable of replacing wood and method for manufacturing same

A lightweight, keel technology, used in building components, buildings, ceilings, etc., can solve the problems of non-compliance with fire safety requirements, difficult processing and high production costs, and achieve good toughness, light weight, and low production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, a non-combustible lightweight keel that can replace wood of the present invention, it includes the following components and parts by weight: cement 25, magnesium oxide 5, aluminum oxide 1.5, silicon dioxide 40, calcium oxide 21, Reinforcing fiber 2, vegetable fiber 15, admixture 0.008, and auxiliary agent 1; wherein, the admixture is moisture-proof liquid; the auxiliary agent is industrial alkali; the reinforcing fiber is glass fiber.

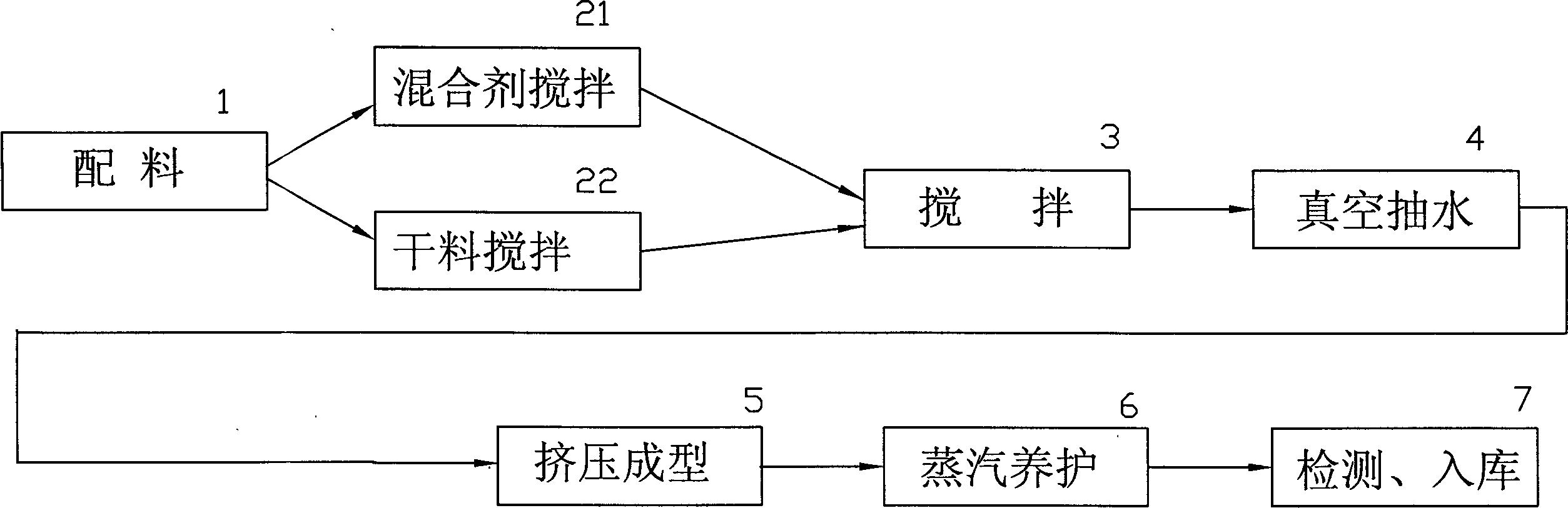

[0042] see figure 1 Shown, lightweight keel of the present invention is made by following steps;

[0043] Step a is the batching process 1. This process is to select cement, magnesia, aluminum oxide, silicon dioxide, calcium oxide, glass fiber, vegetable fiber, moisture-proof liquid, and industrial alkali as raw materials, and use the above formula in parts by weight weighing separately;

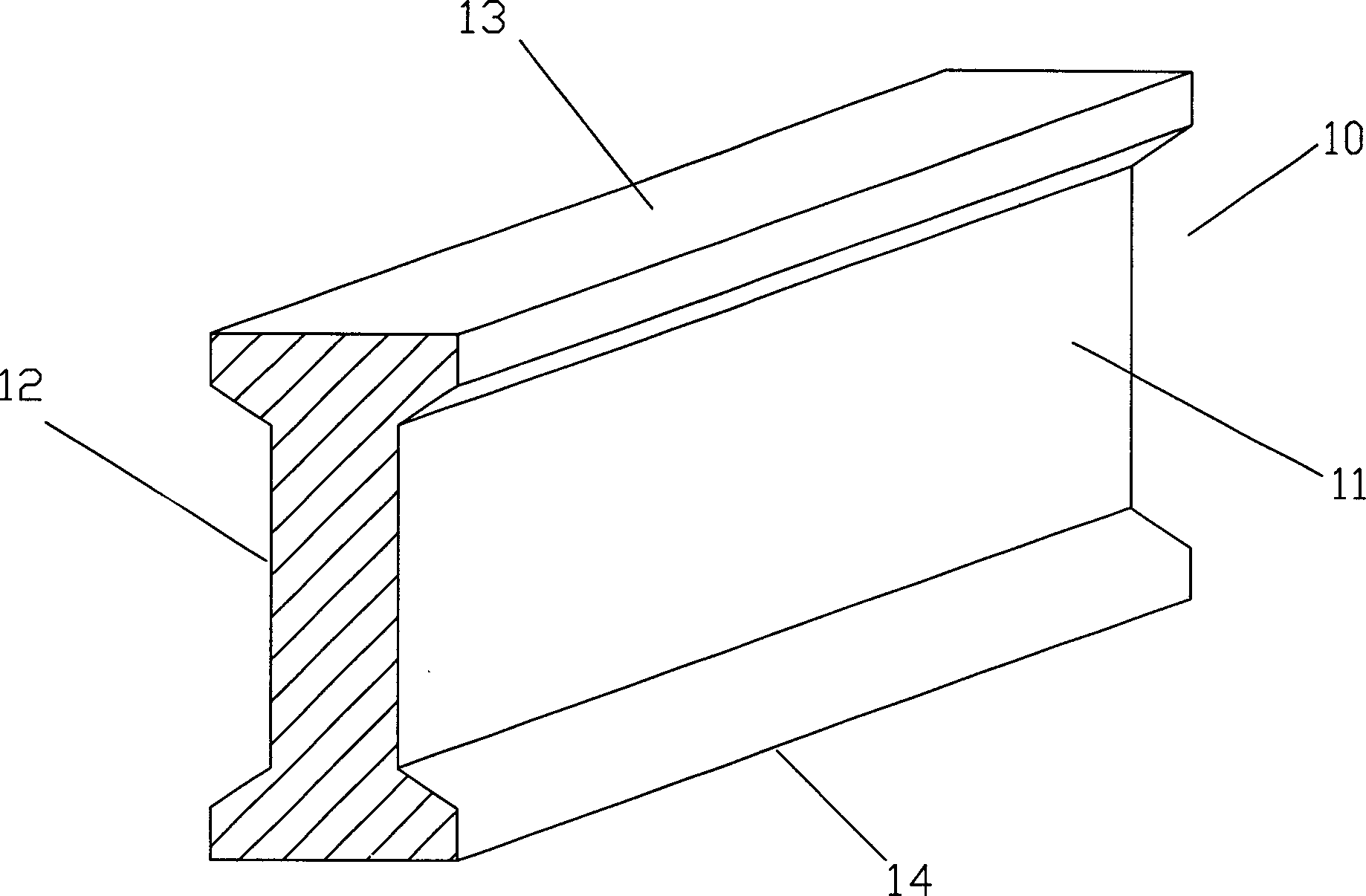

[0044] Step b is the initial mixing process 21, 22. The process 22 is to put the weighed cement, magnesia, aluminum oxide, silicon dio...

Embodiment 2

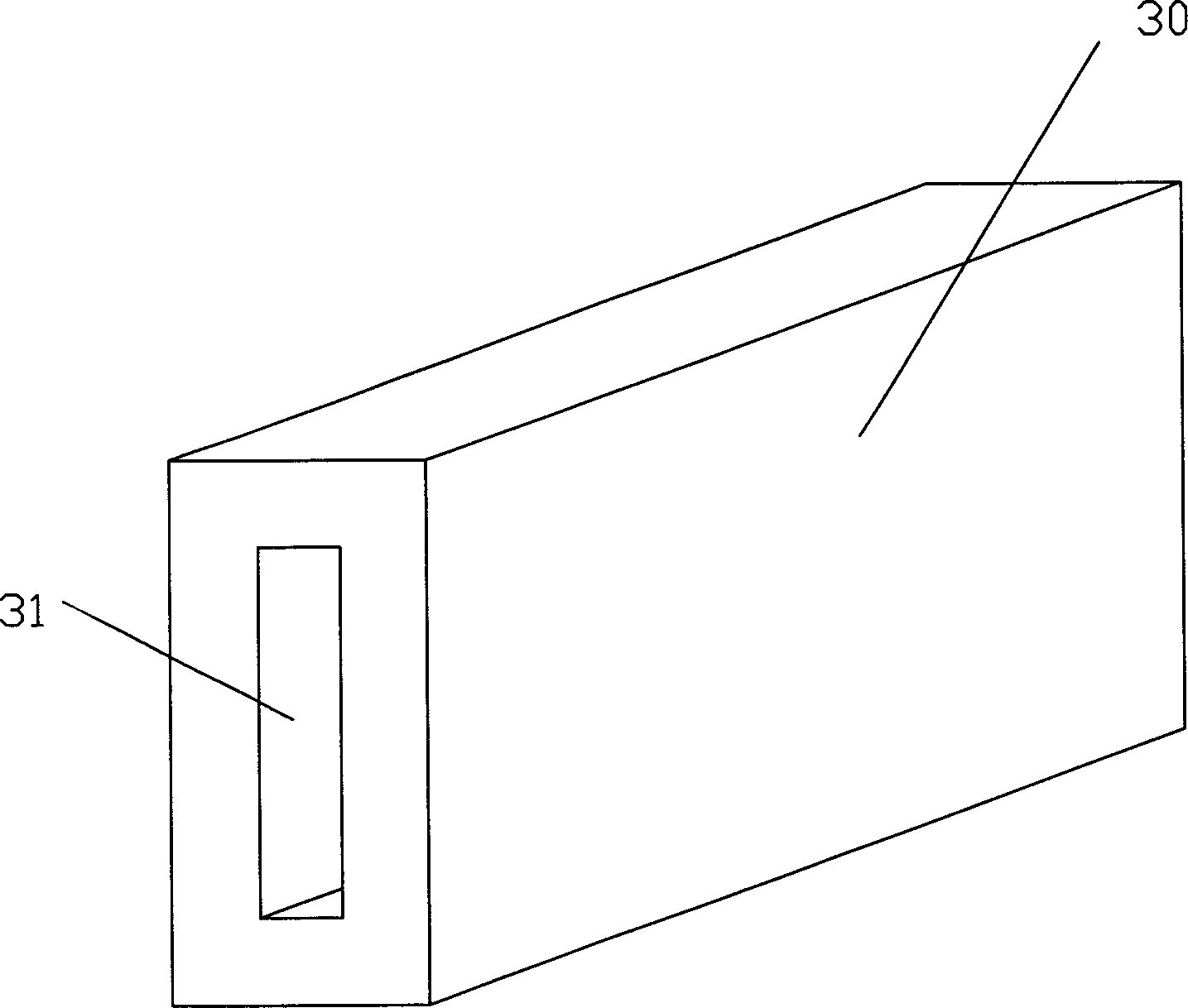

[0053] Embodiment two, see image 3 As shown, a non-combustible lightweight keel that can replace wood in the present invention is different from Embodiment 1 in that it is a strip 30 made by one-time extrusion molding, and the strip 30 has a frame The cross section is rectangular, and the strip 30 is provided with a through hole 31 along the middle of the cross section, and the shape of the through hole 31 is rectangular.

[0054] The keel 30 is more suitable as an aggregate for indoor suspended ceilings, and can also be used as an aggregate for making furniture.

Embodiment 3

[0055] Embodiment 3, a non-combustible lightweight keel that can replace wood of the present invention, it includes the following components and parts by weight: cement 28, magnesium oxide 30, aluminum oxide 0.5, silicon dioxide 37, calcium oxide 6, Reinforcing fiber 8, vegetable fiber 23, admixture 0.075, auxiliary agent 0.35; wherein, the admixture is a moisture-proof liquid; the auxiliary agent is baking soda; the reinforcing fiber is an organic fiber. The above raw materials can be obtained after the steps of batching 1, initial stirring, that is, dry material stirring 22 and mixture stirring 21, stirring 3, vacuum pumping 4, extrusion molding 5, steam curing 6, detection and storage 7, etc. lightweight keel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com