Method for producing antibiotic peptide by using Bacillus amyloliquefaciens and product thereof

A technology of bacillus and starch liquefaction, applied in microorganism-based methods, biochemical equipment and methods, applications, etc., to achieve the effects of stable antibacterial activity, broad antibacterial spectrum, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Bacillus amyloliquefaciens (Bacillus amyloliquefaciens) ES-2 strain (common public strain, 16SrRNA gene sequence GenBank accession number is DQ177319) through the expansion culture of seed, seed medium: tryptone 10.0g, yeast extract 5.0g, NaCl 5.0g , distilled water 1000ml, pH7.2;

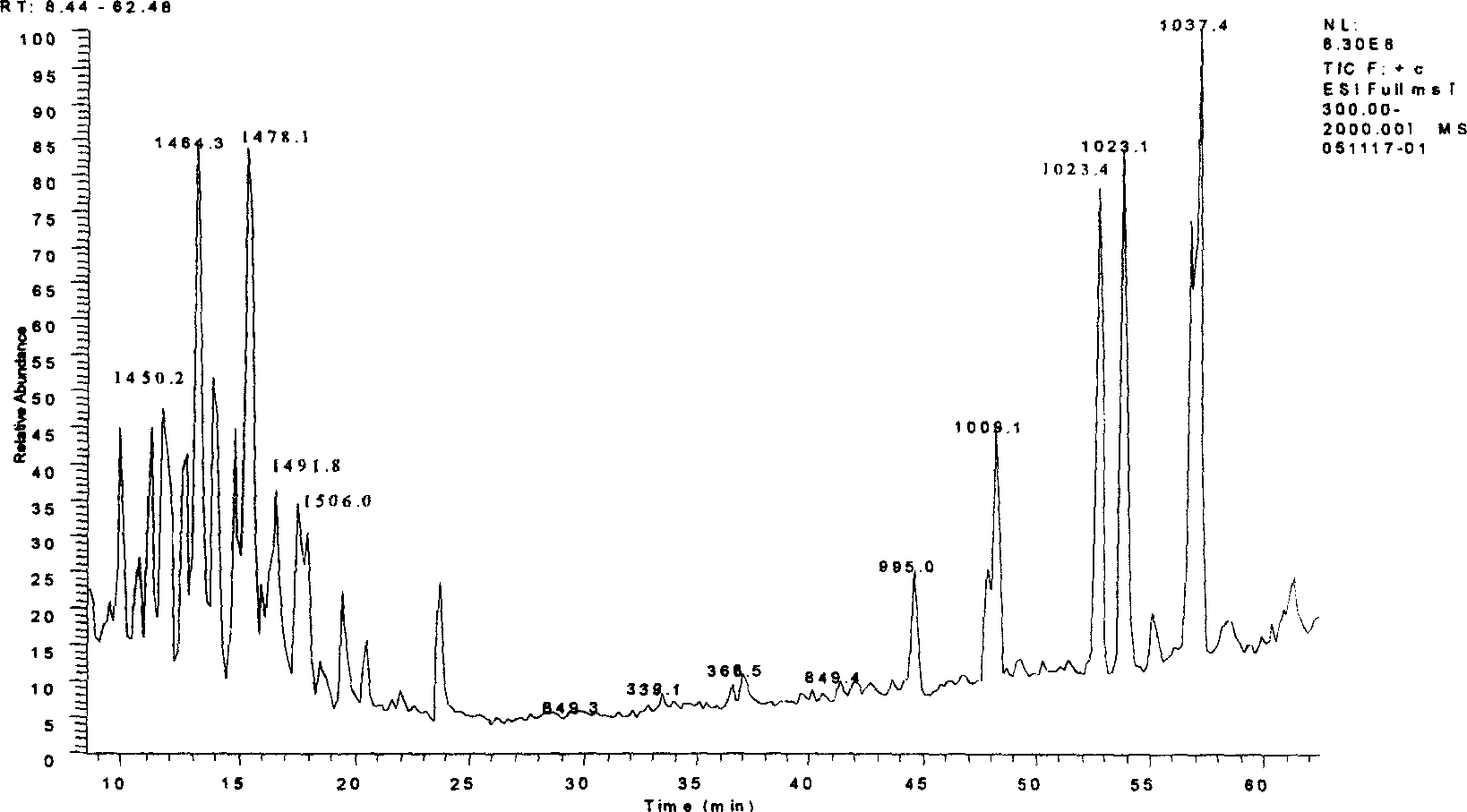

[0027] Then in the fermenter at 28-35°C, carry out liquid submerged fermentation for 30-48h (liquid fermentation medium: glucose 20.0g, tryptone 5.0g, MgSO 4 0.5g, KCl 0.5g, KH 2 PO 4 1g, FeSO 4 0.15mg, MnSO 45.0mg, CuSO 4 0.16mg, distilled water 1000ml, pH7.0. ) to accumulate antibacterial metabolites, the fermentation broth is centrifuged to remove bacteria, and then the supernatant is concentrated and dried to obtain the finished antibacterial peptide. As determined by high performance liquid chromatography, the antimicrobial peptide content is not less than 100g / kg. As determined by LC-MS, the antimicrobial peptide product is a mixture of two homologues of lipopeptide surfactin...

Embodiment 2

[0029] Bacillus amyloliquefaciens (Bacillus amyloliquefaciens) ES-2 is expanded and cultivated through seeds, and then submerged in a fermenter at 28-35°C for 30-48 hours (liquid fermentation medium: glucose 20.0g, tryptone 5.0g, MgSO 4 0.5g, KCl 0.5g, KH 2 PO 4 1g, FeSO 4 0.15mg, MnSO 4 5.0mg, CuSO 4 0.16mg, distilled water 1000ml, pH7.0. ), accumulate antibacterial metabolites, the fermentation liquid is centrifuged to remove the bacteria, then add HCl to the supernatant to adjust the pH to 2, centrifuge after standing, and the precipitate is further extracted with methanol, and the extract is adsorbed and dried by the excipient to obtain The finished product of antimicrobial peptide, as determined by high performance liquid chromatography, has an antimicrobial peptide content of not less than 100g / kg.

Embodiment 3

[0031] Bacillus amyloliquefaciens (Bacillus amyloliquefaciens) ES-2 is expanded and cultivated through seeds, and then submerged in a fermenter at 28-35°C for 30-48 hours (liquid fermentation medium: glucose 20.0g, tryptone 5.0g, MgSO 4 0.5g, KCL 0.5g, KH 2 PO 4 1g, FeSO 4 0.15mg, MnSO 4 5.0mg, CuSO 4 0.16mg, distilled water 1000ML, pH7.0. ), accumulating antibacterial metabolites, the fermentation liquid is centrifuged to remove the thalline, then adding 25% ethyl acetate by volume to the supernatant for extraction, drying after extraction, and the extract is adsorbed by excipients to obtain the finished product of antibacterial peptides, As determined by high performance liquid chromatography, the antimicrobial peptide content is not less than 100g / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com