Fuel cell

A slurry and electrode technology, applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of productivity, manufacturing time, etc., and achieve the effect of shortening the working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

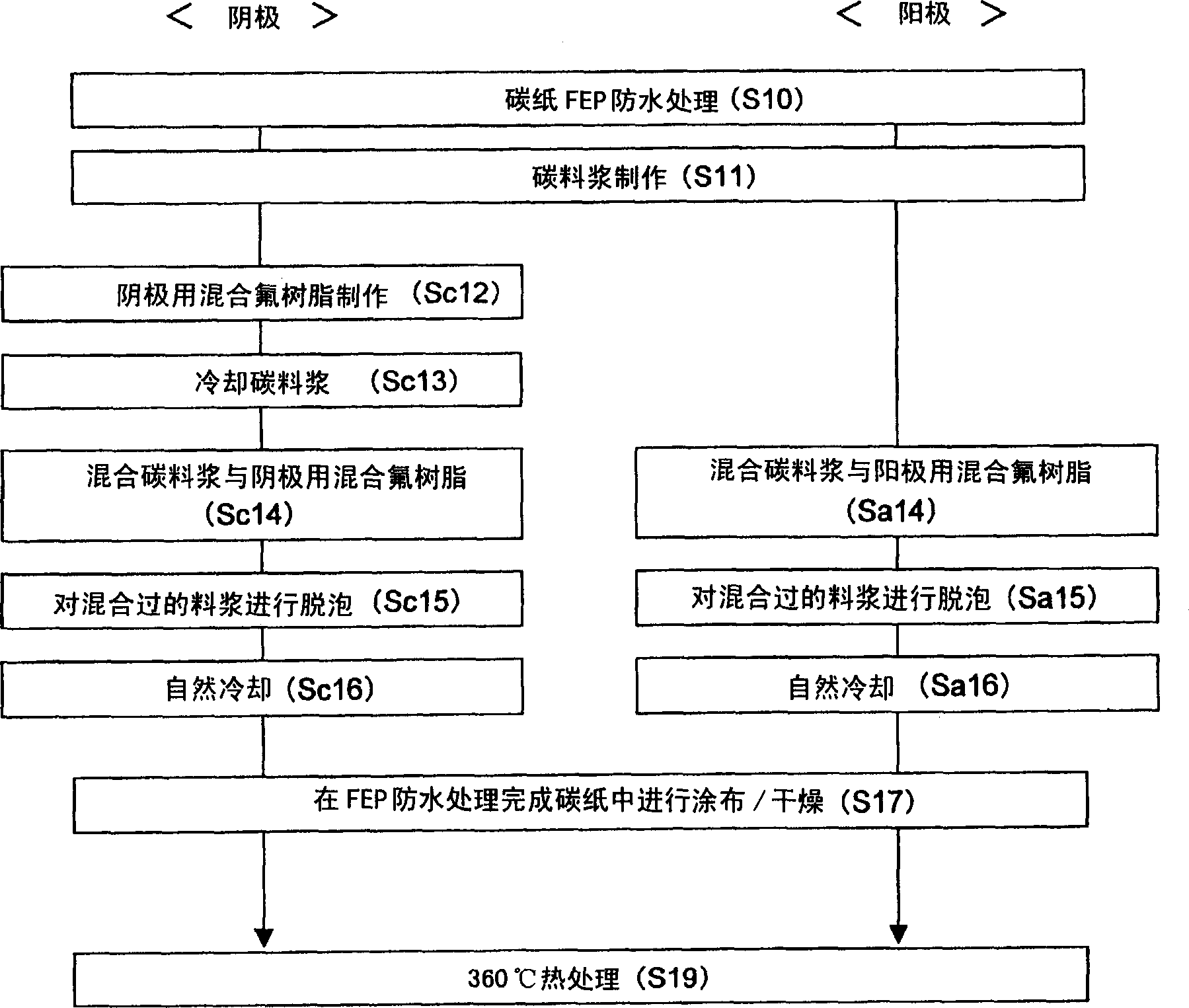

[0030] Such as figure 2 As shown, the carbon paper (manufactured by Dongling Corporation: TGPH060H) as the base material of the gas diffusion layer has a weight ratio of carbon paper: FEP (tetrafluoroethylene-hexafluoropropylene copolymer) of 95:5 (for the cathode), 60 : 40 (for anode) was immersed in the FEP dispersion liquid, and then dried at 60° C. for 1 hour, and then heat-treated at 380° C. for about 15 minutes (FEP water-repellent treatment) (S10). In this way, almost uniform water repellency treatment is applied to the carbon paper.

[0031] Carbon block (manufactured by CABOT: Vulcan XC72R), terpineol (manufactured by Kishida Chemical Co., Ltd.) as a solvent, and triton (manufactured by Kishida Chemical Co., Ltd.) of a nonionic surfactant were used as carbon black in a weight ratio. : terpineol: triton = 20:150:3, mixed at room temperature for 60 minutes in a universal mixer (manufactured by DALTON) to make it uniform, and prepared a carbon slurry (S11).

[0032] A...

Embodiment 2

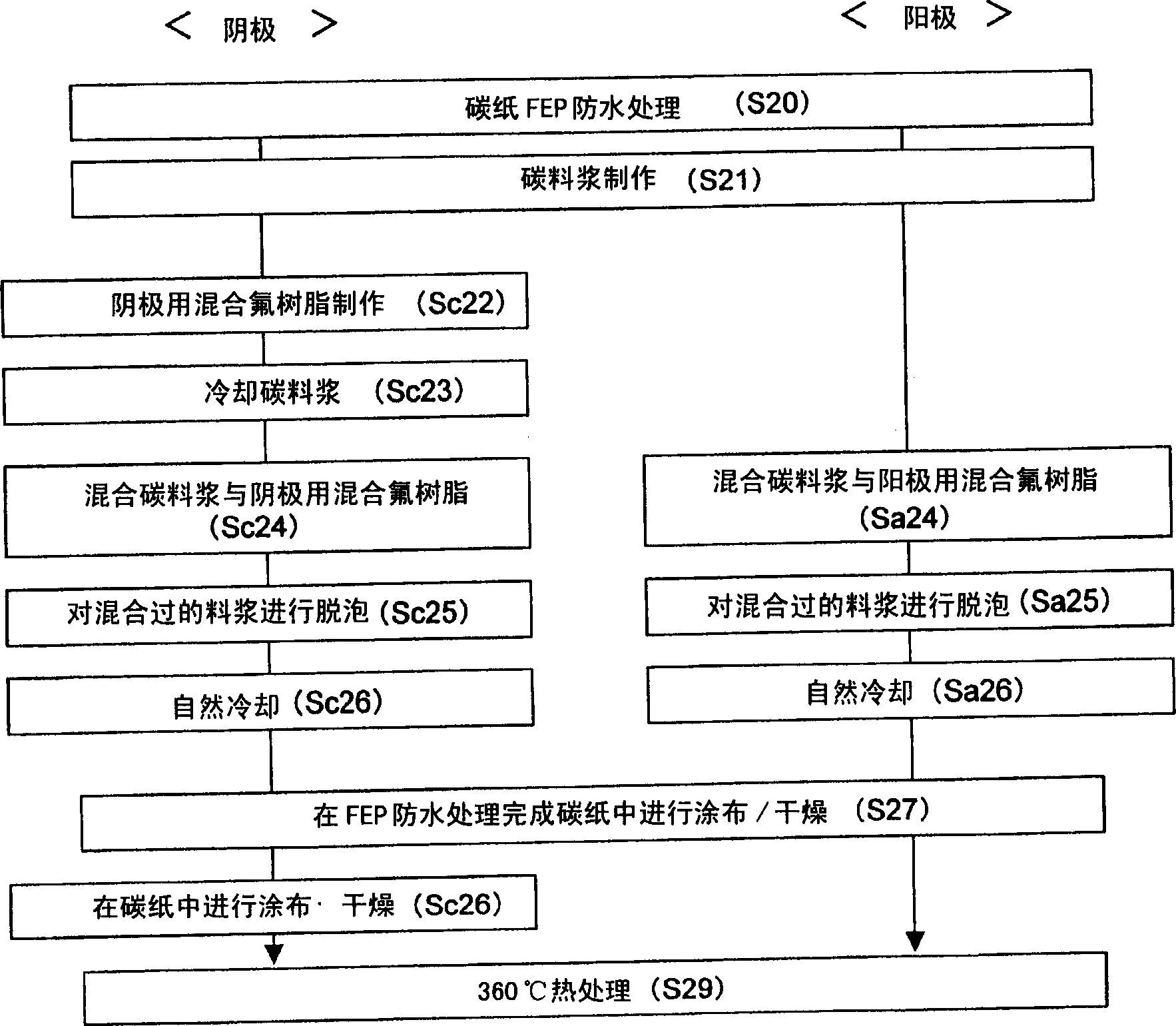

[0036] Such as image 3 As shown, carbon paper (manufactured by Toling Corporation: TGPH060H) as a base material of the gas diffusion layer was subjected to the same FEP water repellent treatment as in Example 1 (S20).

[0037] Same as embodiment 1, carbon black, terpineol, triton are carbon blocks in weight ratio: terpineol: triton = 20: 150: 3, mix 60 minutes at normal temperature in the universal mixer, make Carbon slurry (S21).

[0038] As in Example 1, a cathode gas diffusion layer slurry and an anode gas diffusion layer slurry were prepared.

[0039] Coat each gas diffusion layer slurry that has been cooled to room temperature on the surface of the above-mentioned carbon paper that has been subjected to FEP waterproof treatment, and make the coating state in the carbon paper surface uniform, and dry it at 60°C for 60 minutes with a hot air dryer (S27). After drying the gas diffusion layer on the cathode side with a hot air dryer, the cathode gas diffusion layer slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com