Method for reduction preparation of silver nanowire by composite solvent

A composite solvent, silver nanowire technology, applied in the field of metal powder material preparation, to achieve high yield and environment-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

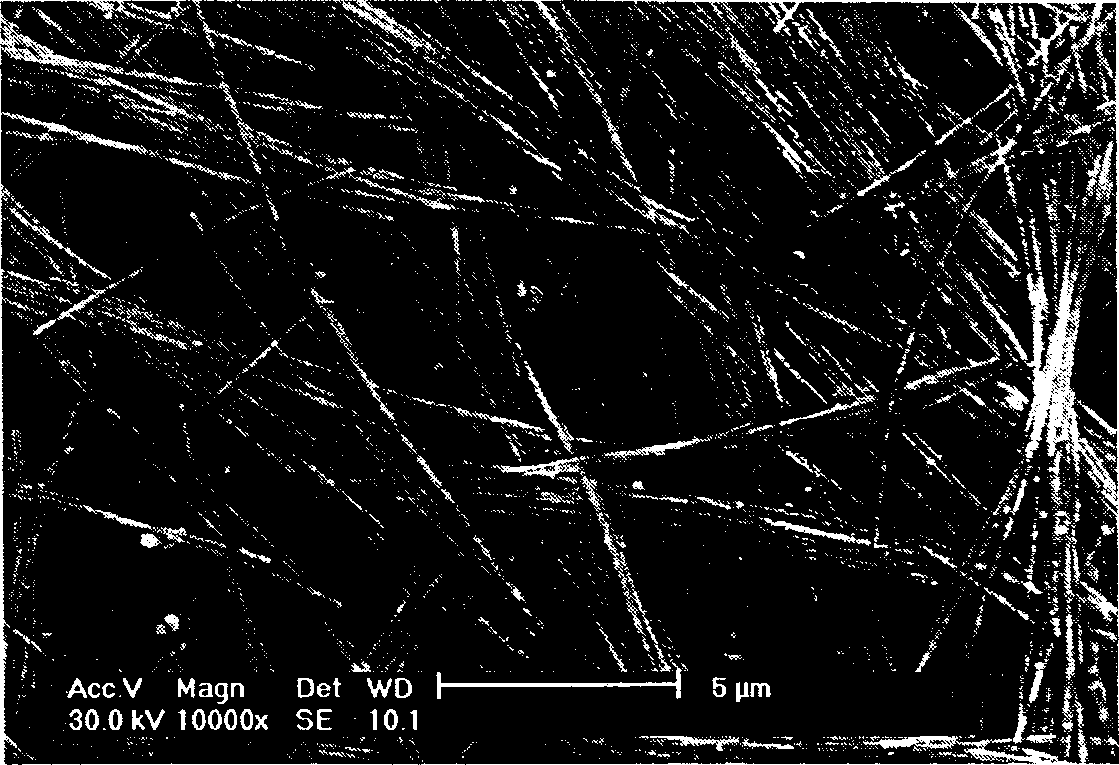

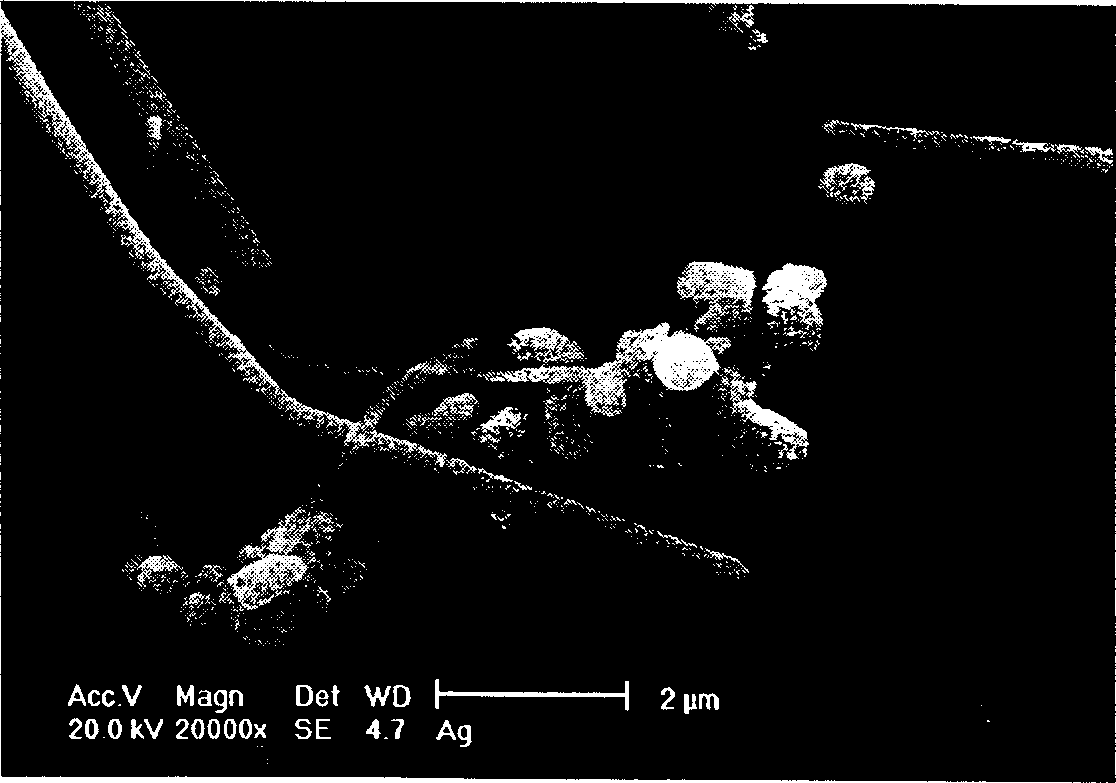

[0018] In a polytetrafluoroethylene reaction kettle, weigh 2.8g of template dispersant polyvinylpyrrolidone, add 100ml of glycerol, 10ml of water composite solvent, heat the temperature of the reaction kettle to 120°C, and reflux for 20 minutes; use nitric acid with a purity of 99.5% Silver is added into the mixed solution of glycerol and deionized water with a volume ratio of 1:2 and heated slightly to obtain a 1M silver nitrate solution; 60ml of this solution is used to spray the composite solvent in batches, and the speed of spraying can be 3g / m 2 .s~10g / m 2 Between .s, react at 120°C for 4 hours, separate, wash once with acetone or deionized water, and dry in vacuum. The obtained powder is subjected to physical and chemical testing to obtain 6.25 g of silver nanowires. exist figure 1 It can be seen in the silver nanowires composed of a large number of filaments with a length of tens of microns.

Embodiment 2

[0020] According to the method and dosage of Example 1, the amount of PVP was added to 11.2 g, the temperature of the reactor reached 160° C., and the reaction was carried out for 4 hours to obtain nano-silver nanowires, and the product was 6.32 g.

Embodiment 3

[0022] According to the method of Example 1, 100ml glycerol, 100ml water, PVP2.8g, spray 40ml1MAgNO 3 solution, the reaction kettle temperature is 90°C, and react for 4 hours to obtain a dark yellow silver sol with uniform silver nanowires, and the maximum visible ultraviolet absorption peak is around 420nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com