Process for preparing nano disperse blue 2BLN dye by reprecipitation-homogenization method

A technology of dispersing blue and reprecipitating, applied in the direction of organic dyes, etc., can solve the problems of wide particle size distribution, irregular particle shape, large particle size, etc., and achieve the effect of easy industrialization, low equipment requirements, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

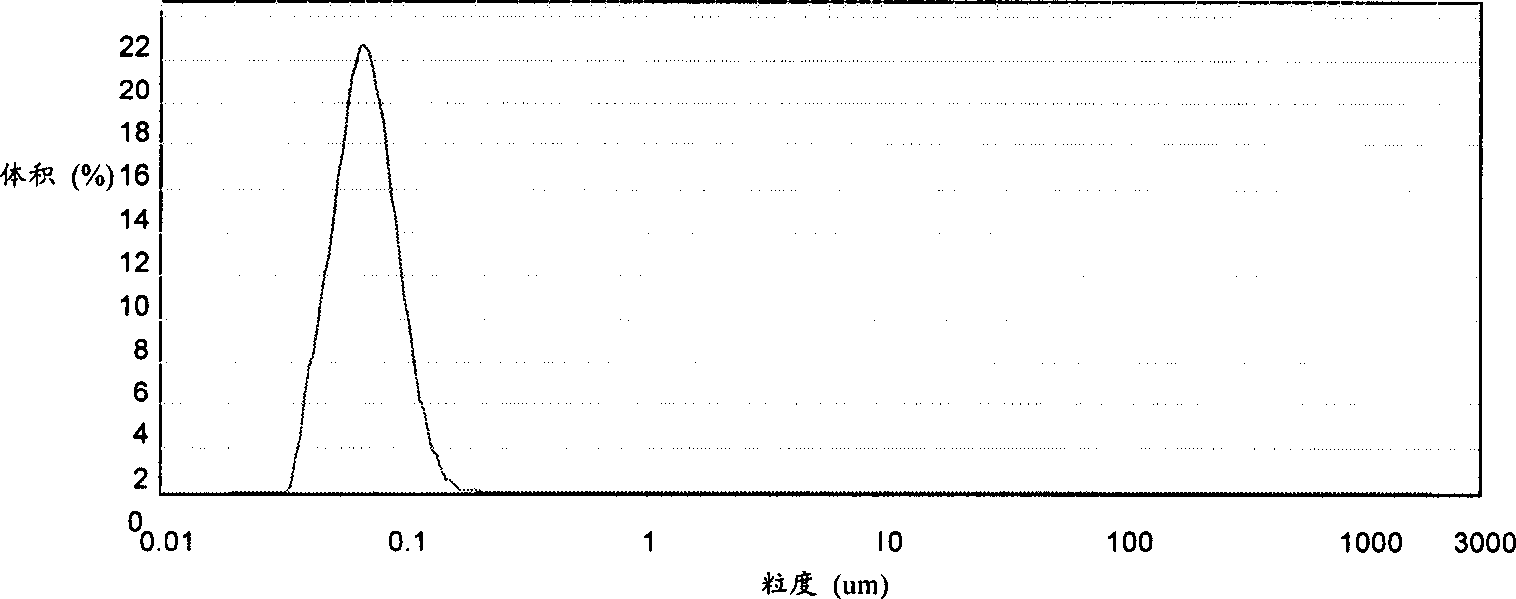

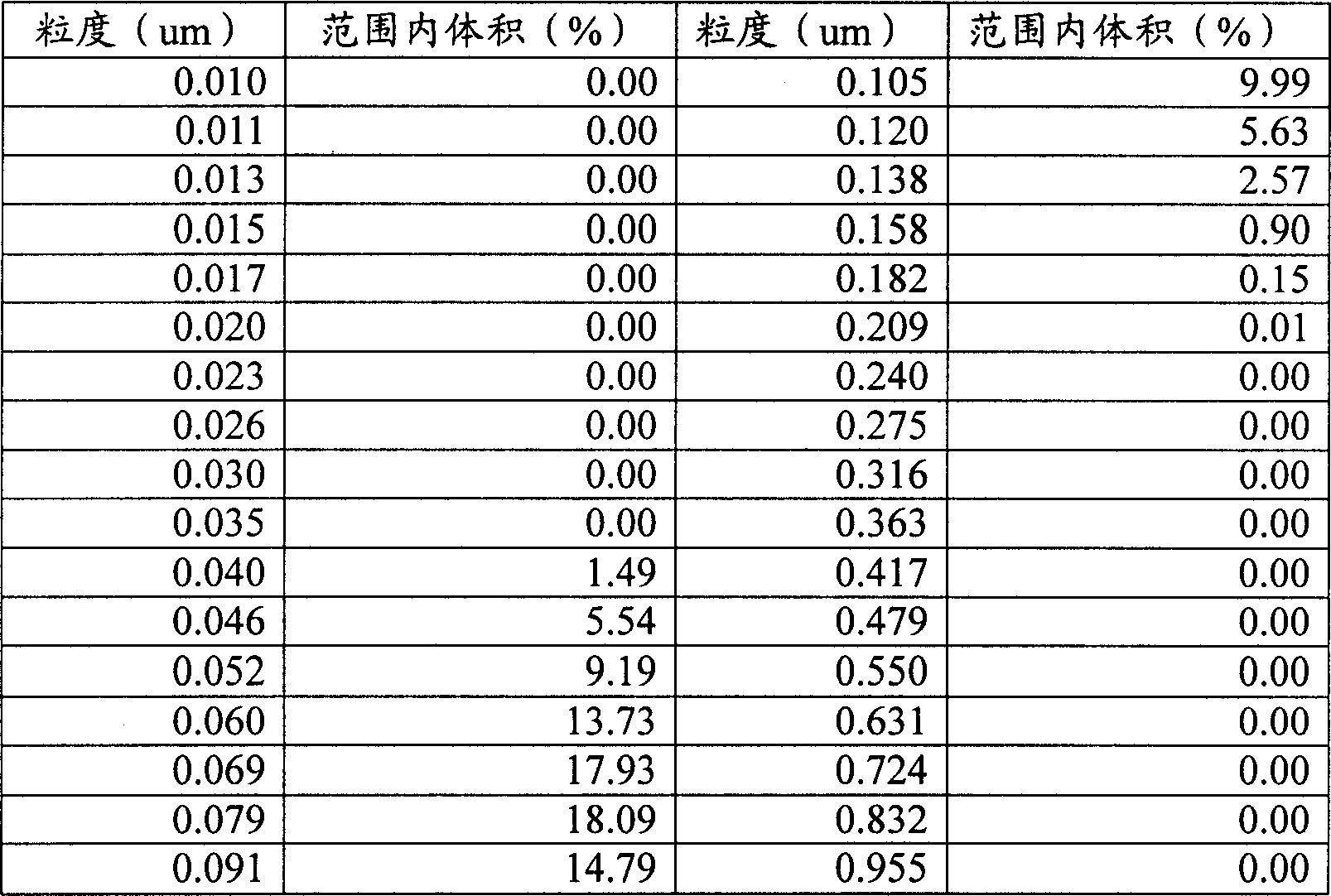

Embodiment 1

[0023] Put 50 g of Disperse Blue 2BLN filter cake, ethanol, and dispersant AS-3 in a weight ratio of 1:2:0.5 into a ball mill for ball milling for 5 hours to obtain a uniform and stable emulsion. Add 20g of dispersant AS-3 to 120g of water. Under the condition of high-speed ball milling, the ball milling medium is zirconia beads of φ1~3mm. Slowly add 75g of the prepared emulsion dropwise, and continue ball milling for 8 hours after dropping. The obtained dye liquid was finally subjected to high-pressure homogenization circulation for 3 times, and the homogenization pressure was 1200 bar, and finally a nano-scale disperse blue 2BLN dye liquid was obtained. After testing the average particle size of the dye solution (D 50 ) is 70nm, 90% particle size (D 90 ) is 98nm.

Embodiment 2

[0025] Put 50 g of Disperse Blue 2BLN filter cake, composite solvent (ethanol: ethylene glycol 4: 1), and dispersant AS-3 in a weight ratio of 1: 1: 0.5 into a ball mill for ball milling for 3 hours to obtain a uniform and stable emulsion. Add 20g of dispersant AS-3 to 120g of water. Under the condition of high-speed ball milling, the ball milling medium is quartz sand of φ1~3mm. Slowly add 150g of the prepared emulsion, and continue ball milling for 6 hours after dripping. The obtained dye liquid was finally subjected to high-pressure homogenization circulation for 3 times, and the homogenization pressure was 1200 bar, and finally a nano-scale disperse blue 2BLN dye liquid was obtained. After testing the average particle size of the dye solution (D 50 ) is 75nm, 90% particle size (D 90 ) is 97nm.

Embodiment 3

[0027] Put 50 g of Disperse Blue 2BLN filter cake, composite solvent (ethanol: ethylene glycol 3.5: 1), and dispersant Reax-85A in a weight ratio of 1: 1: 0.5 into a ball mill for 5 hours to obtain a uniform and stable emulsion. Add 20g of dispersant Reax-85A to 120g of water. Under the condition of high-speed ball milling, the ball milling medium is glass beads of φ1~3mm. Slowly add 120g of the prepared emulsion dropwise, and continue ball milling for 6 hours after dropping. The obtained dye liquid was finally subjected to high-pressure homogenization circulation for 6 times, and the homogenization pressure was 1200 bar, and finally a nanoscale disperse blue 2BLN dye liquid was obtained. After testing the average particle size of the dye solution (D 50 ) is 72nm, 90% particle size (D 90 ) is 94nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com