Paper angle and paper cushion for section bar packaging and production method thereof

A paper corner protector and paper spacer technology, which is applied to wrapping paper, roll-resistant paper, wrapping paper, etc., can solve the problems of affecting waterproofness, not easy to fix, and cannot punch holes, etc., and achieves the effect of high efficiency and low production investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] This product is made of recycled paper pulp, wood pulp board, water repellant, and oil repellent, with one side smooth and one side with a coarser texture. The smooth surface of paper products is covered with PE film. The waterproofing agent generally uses cationic neutral paper glue such as UNT multifunctional waterproofing agent and HFS-I waterproofing agent; in order to strengthen the waterproofing performance of the product, an oil-proofing agent of dry pulp weight (1-3%) is added to the pulp. The anti-oil agent used is the imported F321 oil-proof agent of France Atofina Company and DuPont Company of the United States and the domestically produced HF-I oil-proof agent. This kind of oil repellent is a copolymer of water-dispersible fluorine-containing acrylate and other non-fluorine monomers, which has extremely low surface tension and excellent waterproof, oil-proof and stain-proof properties.

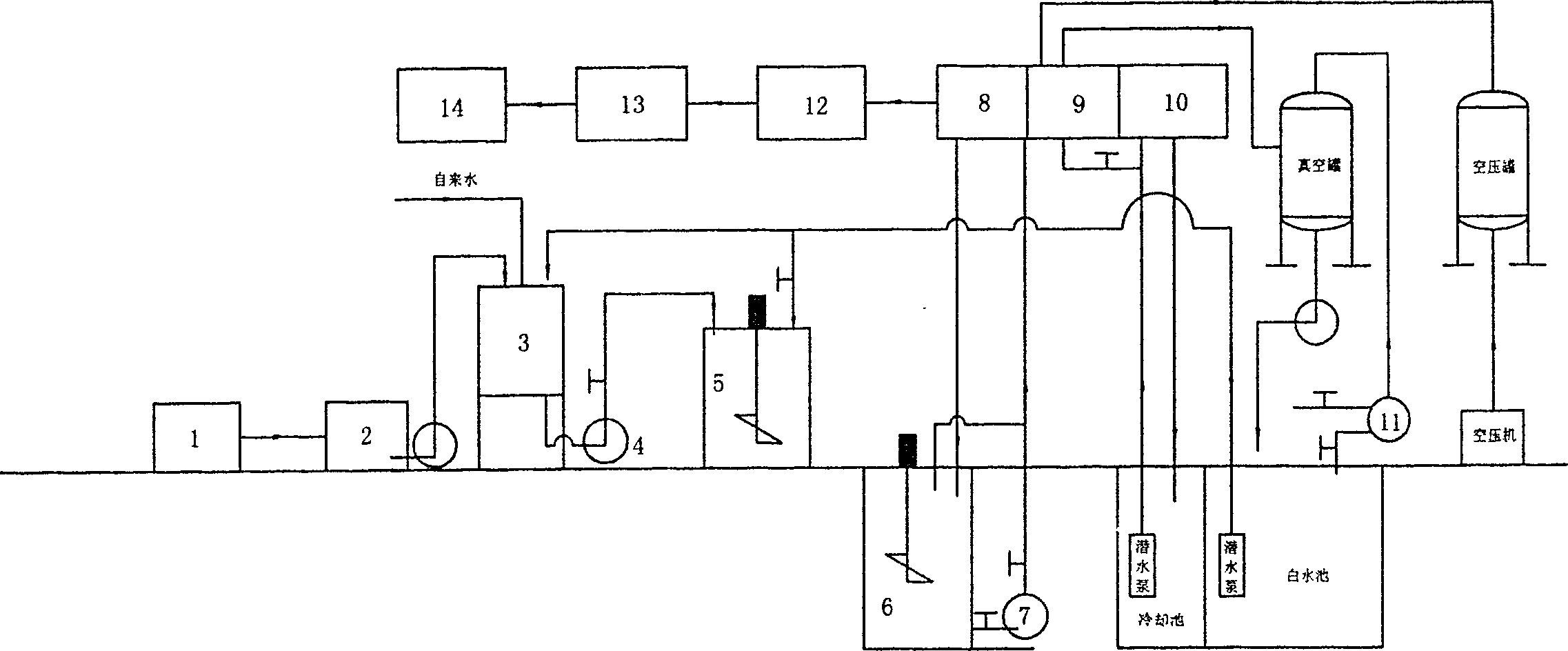

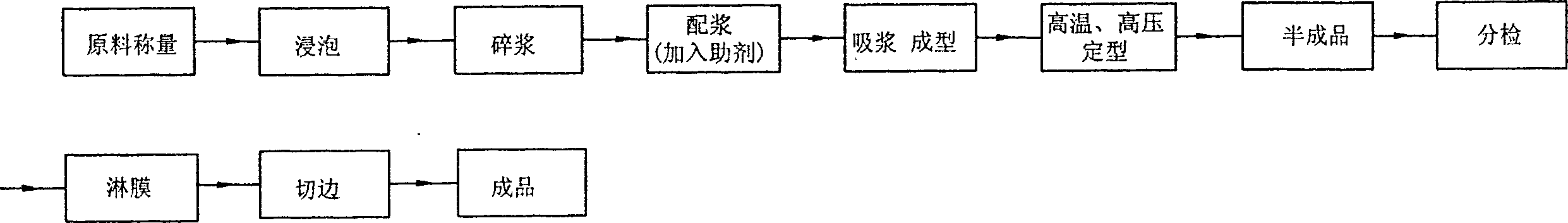

[0012] refer to figure 1 , 2 , the production method of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com