Easy axis oriented FePt, CoPt vertical magnetic recording thin film preparing method

A perpendicular magnetic recording and thin-film technology, which is applied in the field of material preparation, can solve problems such as poor magnetic properties, and achieve the effects of easy control of the process, ensuring the smoothness of the film surface, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following examples are intended to further illustrate the process characteristics of the present invention rather than limit the present invention.

[0016] Preparation of Fe by chemical self-assembly 52 Pt 48 Particles, with an average diameter of 4 nm, were dispersed in hexane and then coated with glass as a substrate. Put the coated glass sheet into a magnetic field, the direction of the magnetic field is perpendicular to the glass surface, and the magnetic field strength is 2T. After the film was dried, the film was subjected to laser heat treatment with a YAG laser with a scanning speed of 1 mm / sec, a pulse current of 16 A, and a repetition frequency of 1 KHz.

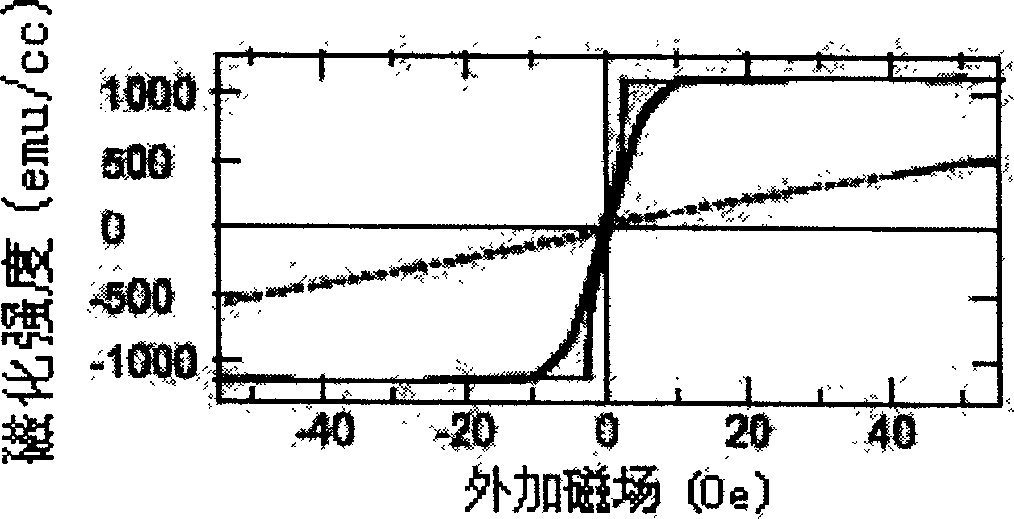

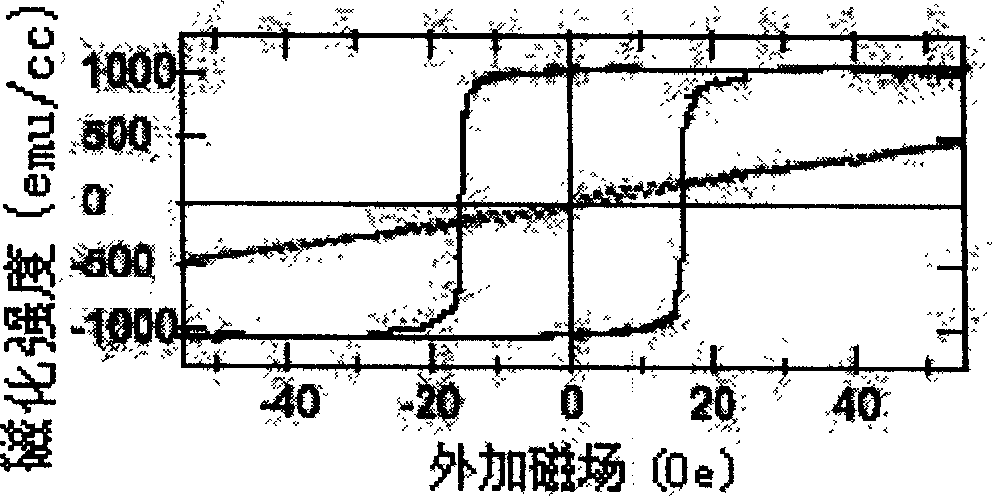

[0017] figure 1 as prepared Fe 52 Pt 48 The magnetization and demagnetization curves of thin films, from figure 1 It can be seen that the coercivity of the magnet is very low, indicating that Fe 52 Pt 48 The particles have a face-centered cubic structure, and the magnets exhibit soft magnetic be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com