Lithium secondary battery containing silicon-based or tin-based anode active material

一种阳极活性、活性材料的技术,应用在二次电池、锂蓄电池、活性物质电极等方向,能够解决电池生产率降低、延长等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

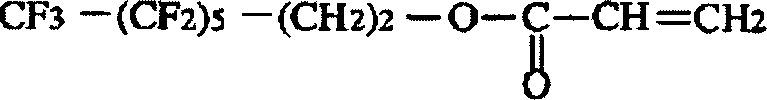

Image

Examples

Embodiment 1-6

[0045] Mixed silicon-carbonaceous material complex (Si-C) as anode active material, the mixture of photocurable monomer or oligomer and photoinitiator given in Table 1 below as binder, and 2% Wt carbon black powder was used as conductive material to prepare anode mixture. Then, 100 parts by weight of N-methylpyrrolidone (NMP) was added as a solvent with respect to 100 parts by weight of the anode mixture. The resulting mixture was stirred for about 30 minutes to prepare an anode slurry. The resulting paste was applied to a copper (Cu) foil with a thickness of about 90 μm to a copper (Cu) foil with a thickness of 18 μm, and was treated with a light dose of 10 J / cm in a UV curing device. 2 Photocuring was performed, followed by solvent heat drying at 130° C. for 1 hour to prepare an anode.

[0046] A cathode mixture was prepared by mixing lithium cobalt oxide as a cathode active material, polyvinylidene fluoride (PVDF) as a binder, and 3% by weight of carbon black powder as a ...

experiment example 1

[0054]In order to evaluate battery performance, for each of the coin batteries prepared in Examples 1-6 and Comparative Examples 1 and 2, changes in battery charge / discharge characteristics were examined using a charge / discharge measuring device. That is, for each coin cell, 2 charge / discharge cycles at a rate of 0.1C and 50 charge / discharge cycles at a rate of 0.5C were repeated at a temperature of 23°C using a constant current / constant voltage method. The capacity retention (%) of the corresponding coin cells at the 50th cycle compared to the initial capacity is shown in Table 1 below. The evaluation was performed using five or more coin cells of Examples 1-6 and Comparative Examples 1 and 2, respectively, and expressed as an average value.

[0055]

Photopolymerizable material (wt%)

anode active material

Content (wt%)

Photoinitiator (wt%)

(%)

Example 1

Bisphenol A (14)

82

UVI-6974(...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com