Scutellarin raw material drug preparing method

A technology for scutellarin and raw materials, which is applied in the field of preparation of high-purity scutellarin, can solve the problems of low yield and the like, and achieves the effects of simple process steps and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

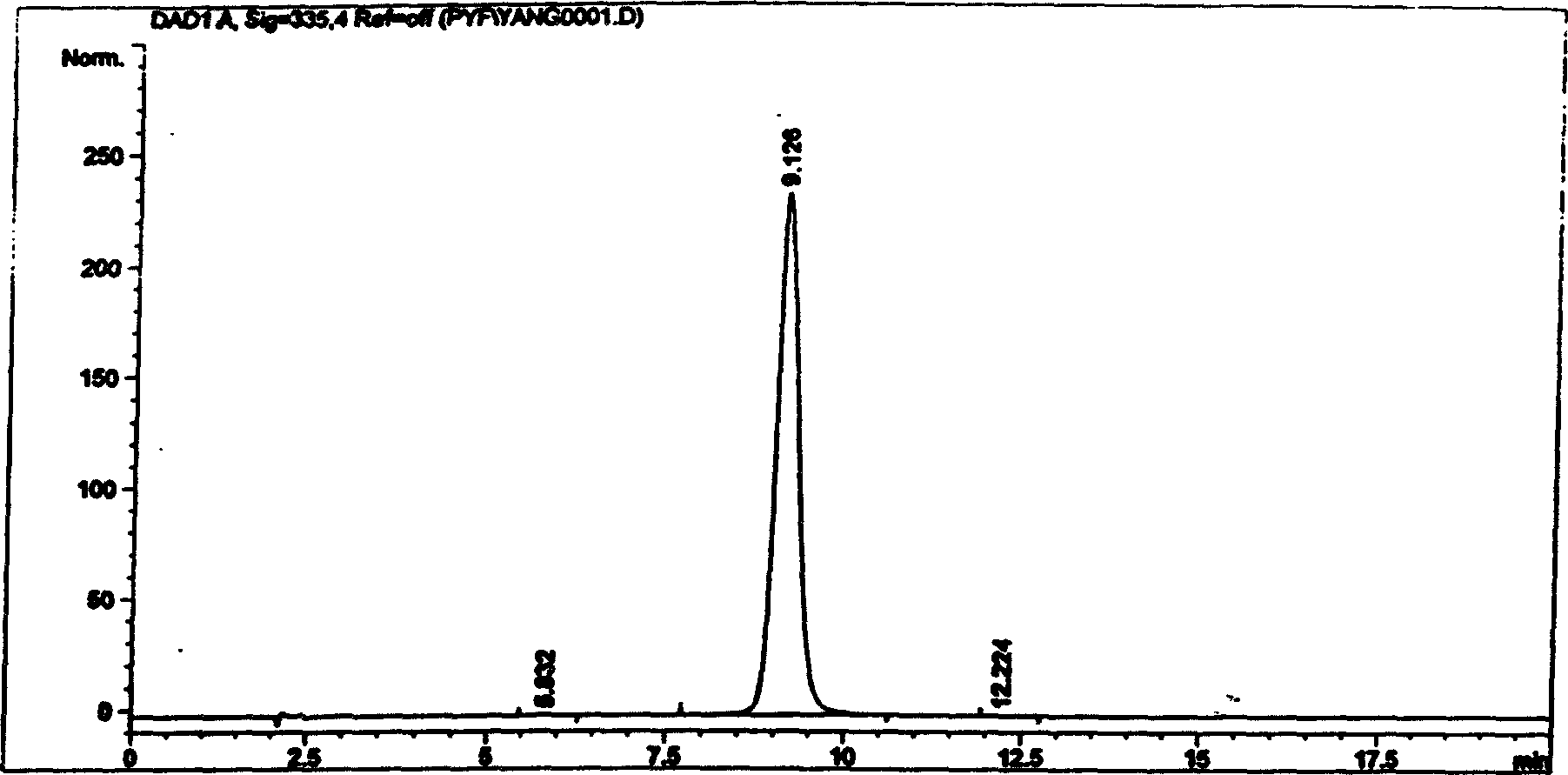

[0035] Weigh 1000g of commercially available breviscapine crude drug, add 30 times the weight of water, adjust the pH value to 7.8 with 10% potassium carbonate test solution, make it completely dissolved, filter, add ethanol precipitation with 1 times the amount of water to the filtrate, and stir while adding , to make the precipitation complete, let stand for 10 hours, filter, add ethanol to wash three times, then move the precipitate to another container, add 25 times the amount of water to dissolve, add 20 times the amount of ethanol, stir, filter, and add 1: 1 Hydrochloric acid to adjust the pH to 2-3 and let it stand for 10 hours, suction filter, wash with water until neutral, wash with ethanol once, dry, and repeat the above steps once. It is refined scutellarin, and its B content is 99.83% through HPLC analysis, as attached figure 1 shown.

Embodiment 2

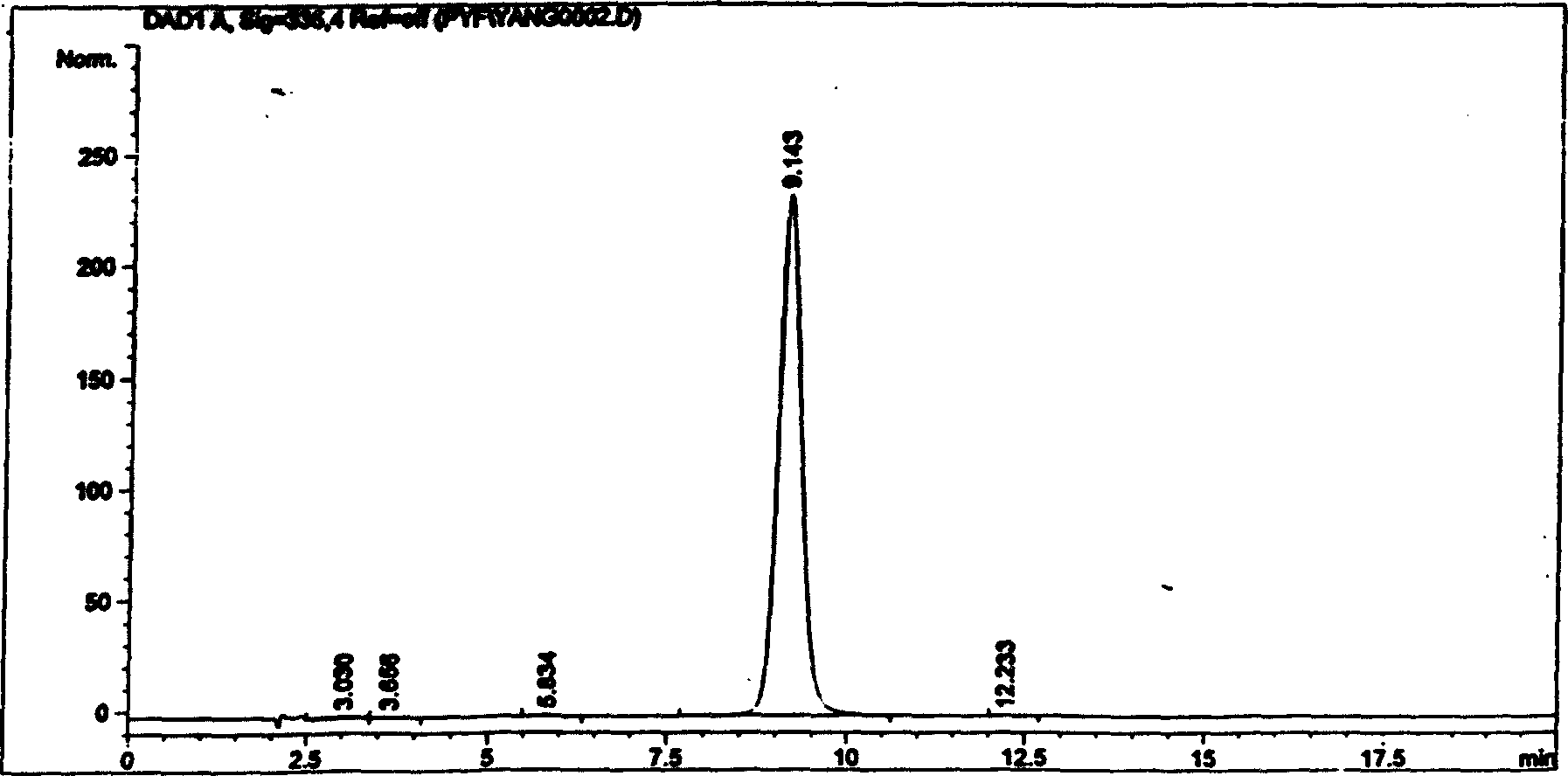

[0037] Weigh 1000g of commercially available breviscapine crude drug, add 15 times the weight of water, adjust the pH value to 6.8 with 10% ammonium carbonate test solution, make it completely dissolved, filter, add 2 times the amount of water to the filtrate to precipitate methanol, and stir while adding , to make the precipitation complete, let stand for 10 hours, filter, add methanol to wash three times, then move the precipitate to another container, add 20 times the amount of water to dissolve, add 10 times the amount of methanol, stir, filter, and add 1: 1 hydrochloric acid to adjust the pH to 1-2 and let stand for 10 hours, filter with suction, wash with water until neutral, then wash with ethanol once, and dry to obtain refined scutellarin. The content of scutellarin is 98.97% by HPLC analysis, as shown in the attached figure 2 shown.

Embodiment 3

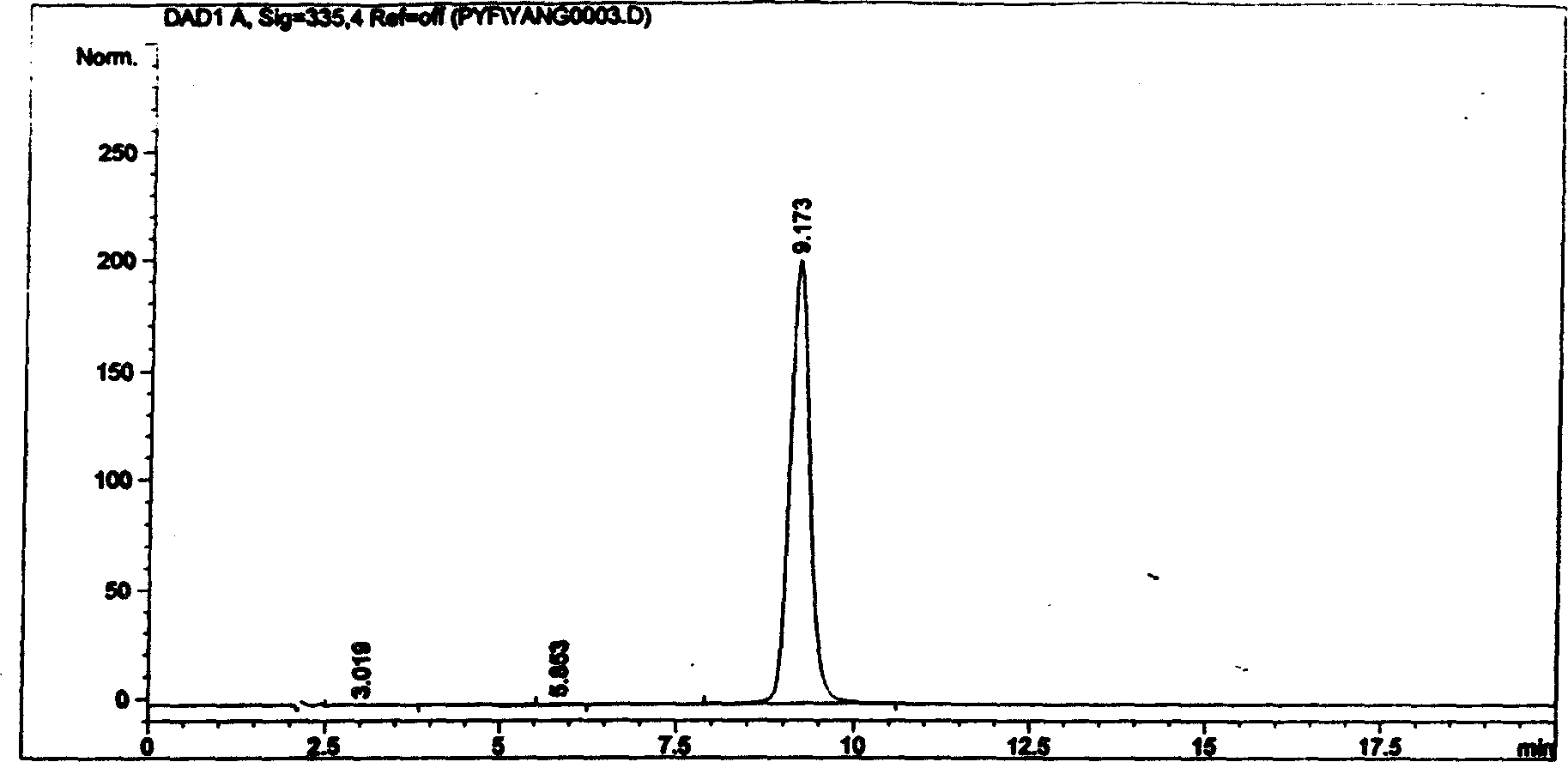

[0039] Weigh 1000g of commercially available scutellarin raw material, add 10 times the weight of water, adjust the pH value to 7.2 with 10% potassium bicarbonate test solution, dissolve completely, filter, add 1.5 times the amount of water to the filtrate to precipitate with acetone, and stir while adding , to make the precipitation complete, let stand for 10 hours, filter, add acetone to wash three times, then move the precipitate to another container, add 12 times the amount of water to dissolve, add 6 times the amount of acetone, stir, filter, and add 1: 1 hydrochloric acid to adjust the pH to 1-2 and let it stand for 10 hours, suction filter, wash with water until neutral, then wash with ethanol once, and dry to obtain refined scutellarin. The content of scutellarin is 99.13% by HPLC analysis, as shown in the attached image 3 shown.

Description of drawings

[0040] Instrument Type: High Performance Liquid Chromatography Gradient Mode: Constant Current

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com