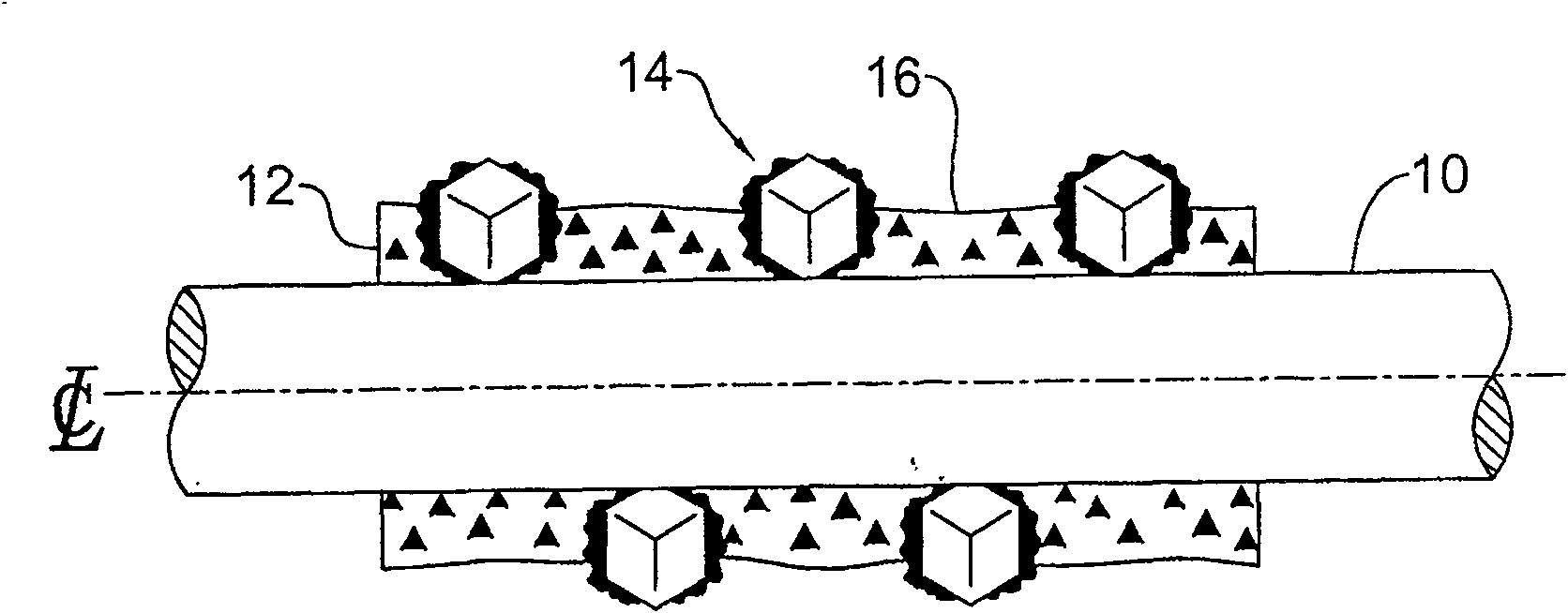

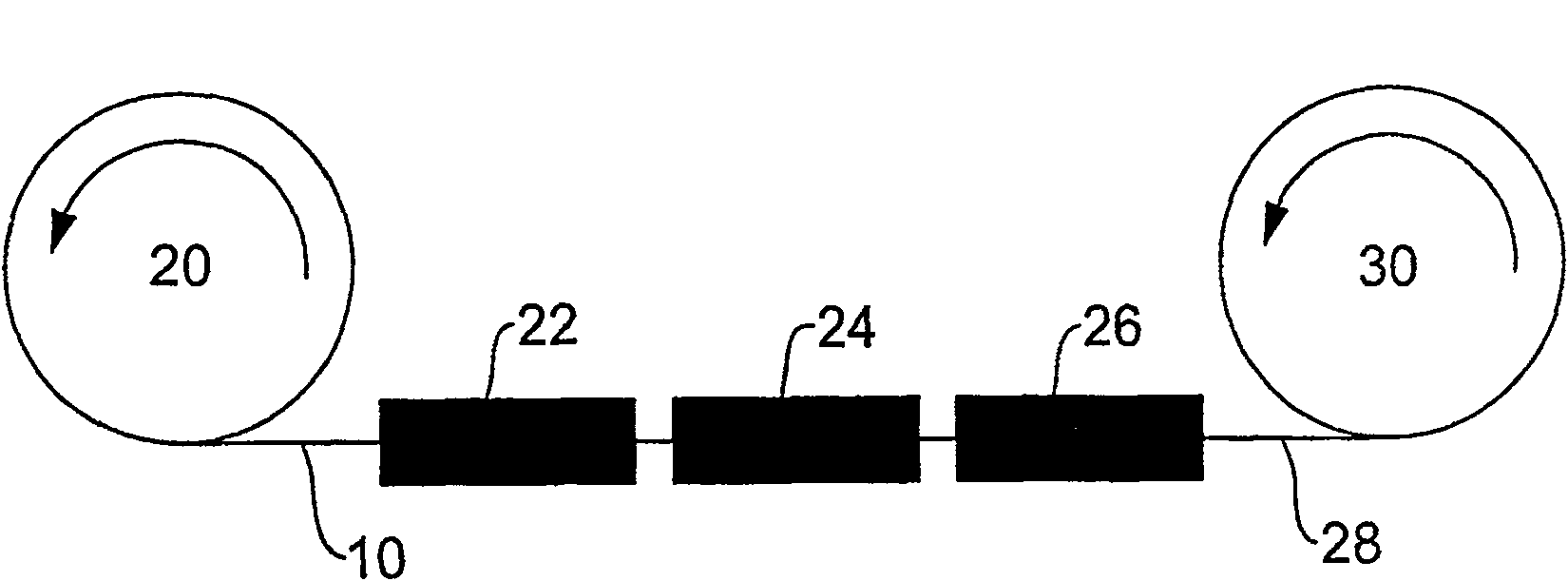

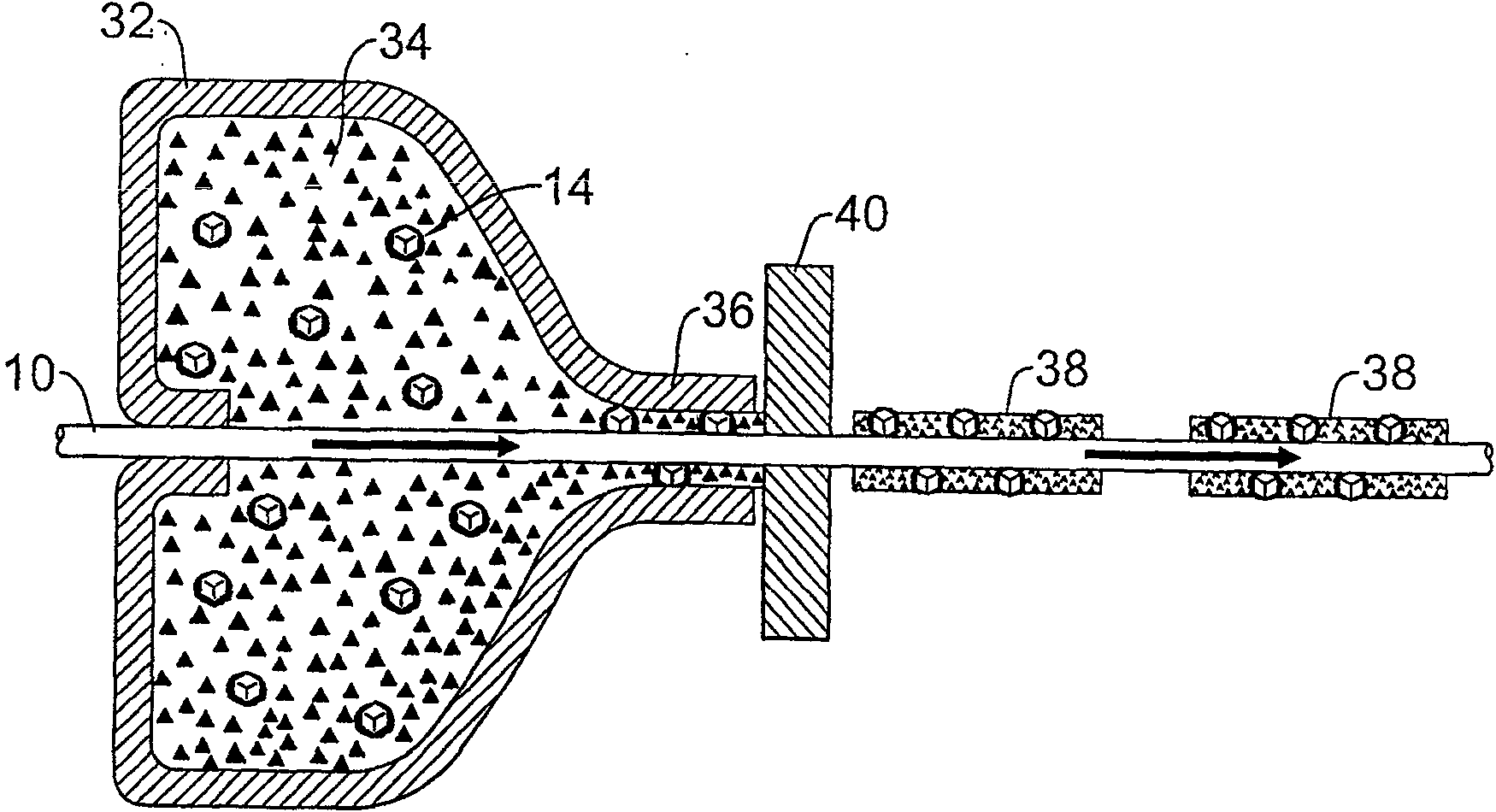

Superabrasive wire saw and associated methods of manufacture

A super abrasive, super technology used in chemistry, physics and materials science to solve problems such as inability to achieve chemical bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] A thin film of an acrylic bond was used to cover the 40 / 50 mesh size diamond grit. The binder-covered diamonds are then mixed with a powdered metal alloy containing B, Ni, Cr, Si (which has an average particle size of about 325 mesh size and is available under the trade name NICROBRAZ Wall Colmonoy Company) mixing. The result is a brazed powder-coated diamond. Then the coated abrasive grains were mixed with Al 2 o 3 fine powder mix. in a vacuum furnace at a pressure of 10 -5 The mixture was heated at torr for about 17 minutes, to a maximum temperature of about 1005° C. to ensure that the metal alloy coating melted, liquefied and flowed around the diamond grit to wet it out. The mixture was then cooled and removed from the vacuum oven. Diamond abrasive grains and Al 2 o 3 After separation, many coated abrasive grains were mixed with a cobalt powder and sintered in a hot press to form rectangular segments. Use pliers to bend to break some of these pieces off. T...

Embodiment 2

[0080] Same process as in Example 1, but using diamond abrasive grains with an average particle size of about 325 to about 400 meshes instead of Al 2 o 3 Powder release agent. During the heating process, the solder alloy coating infiltrates the smaller diamond grains and forms a chemical bond with the outside of the coated diamond grains. Thus, a coating of diamond abrasive grains is produced having chemical bonds with the metal alloy shell, with the smaller diamond abrasive grains further bonded to the outside of the shell. These "spiky" coated abrasive grains were incorporated into a cobalt matrix and fracture tested as above with similar results.

Embodiment 3

[0082] Same procedure as Example 2, but using SiC abrasive grains instead of smaller diamond abrasive grains. This process resulted in a diamond grit coating with ceramic grits bonded to the outside of the metal coating similar to the diamond grit of Example 2. Furthermore, similar results to those of Example 1 and Example 2 were obtained in this fracture test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com