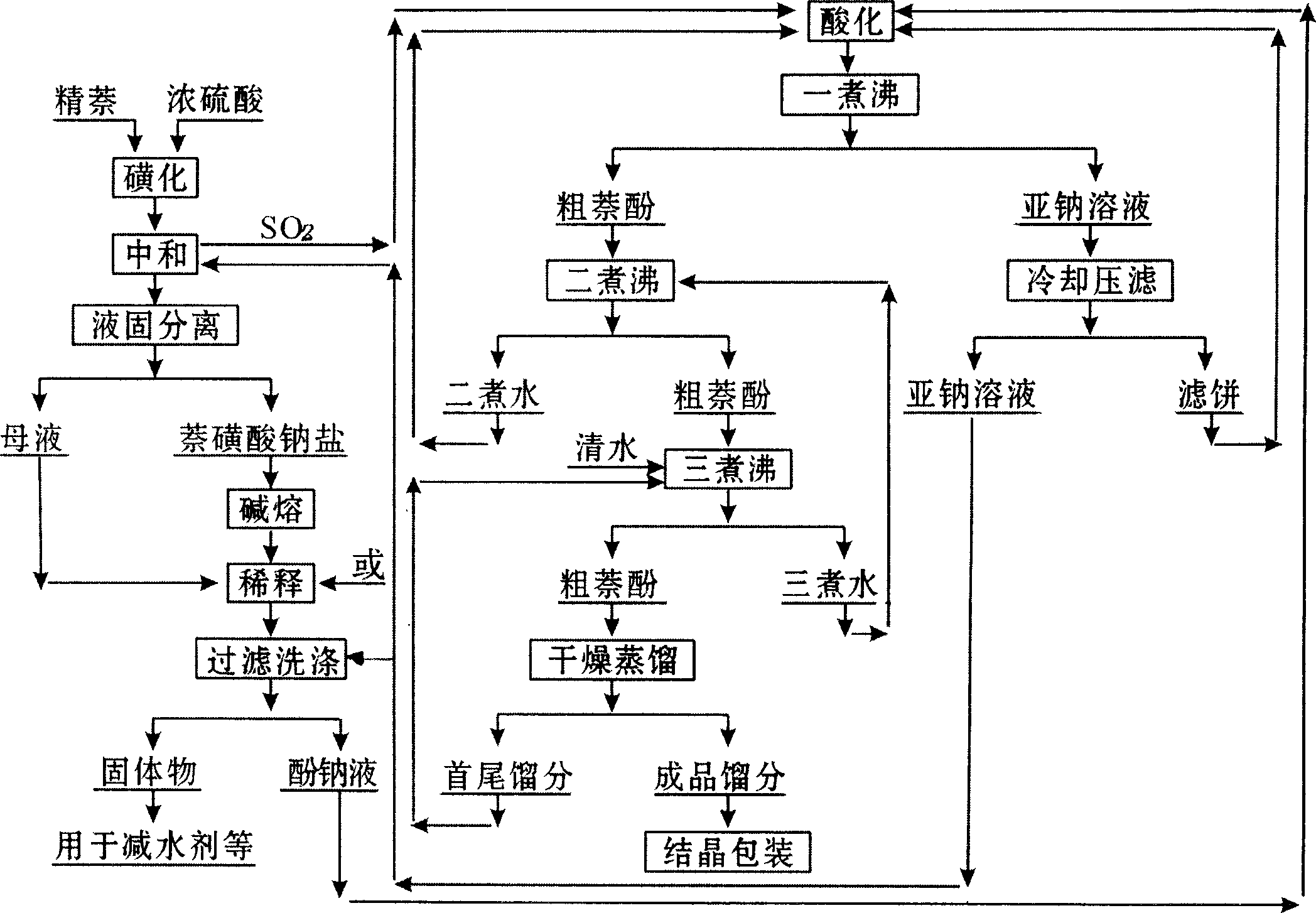

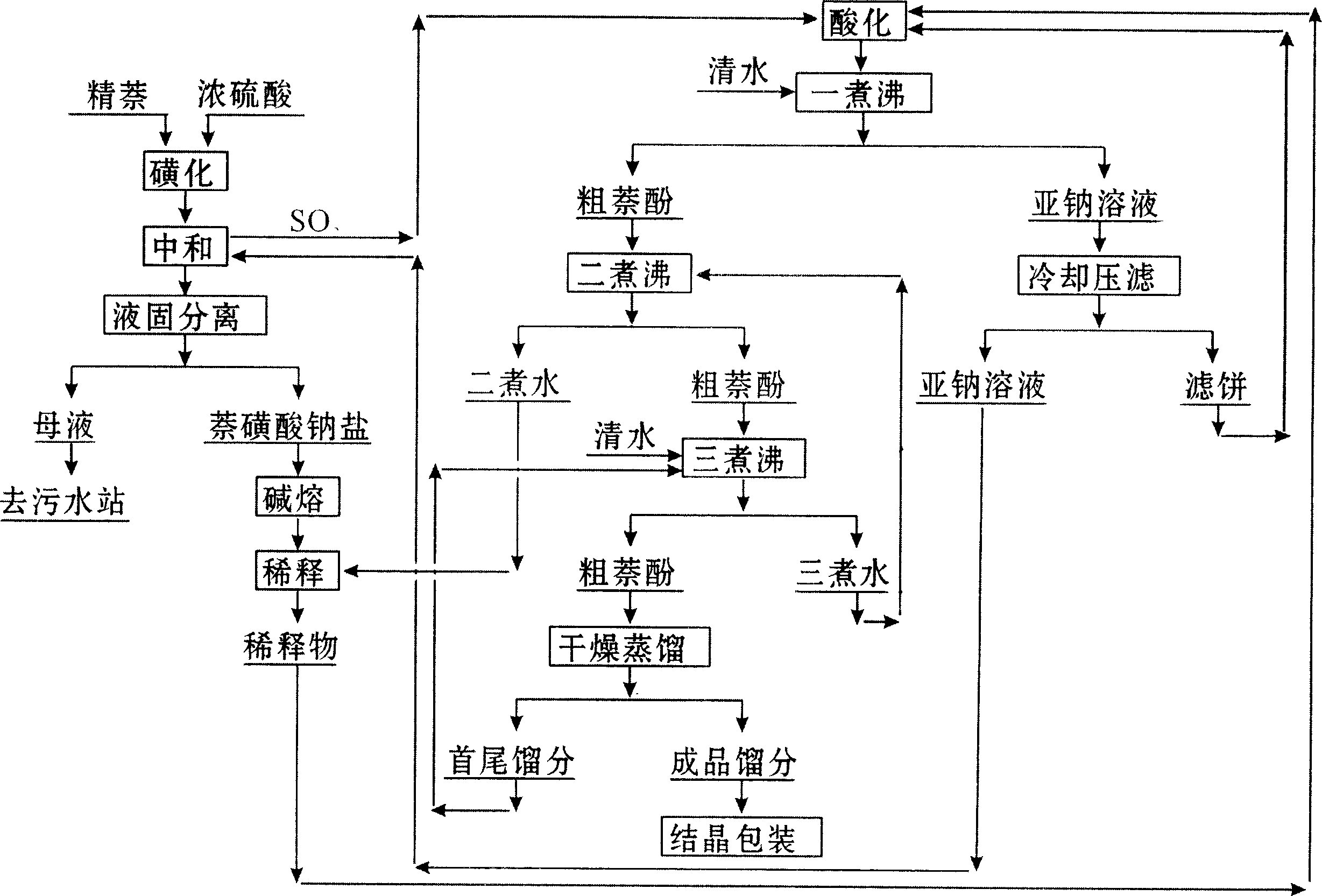

Processing method for mother solution and solium sulfite solution in naphthol production

A technology of sodium sulfite and treatment method, applied in the preparation of alkali metal sulfite, neutralized water/sewage treatment, alkali metal sulfite/sulfite, etc., to increase economic benefits, reduce acid consumption and steam consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, in volume is 8m 3 Add 5 tons of naphthalenesulfonic acid sodium salt mother liquor to the dilution pot, slowly put the alkali melt (reinforced alkali 900kg / batch of ingredients) generated by the alkali fusion reaction into the dilution pot, stir with a stirrer, and use the 85°C dilution with 0.2MPa compressed air is sent to the plate and frame filter press for liquid-solid separation, and then 500 liters of sodium sulfite solution at 85°C is sent to the plate and frame filter press with compressed air to wash the filter cake, and then dried with compressed air. Obtain 1250kg of solid salt mixture, the main components of the solid are sodium sulfite, sodium sulfate and sodium naphthalenesulfonate, etc., which can be used in the production of water reducers, and the liquid after pressure filtration and the second boiling washing water in production are removed to the acidification pot for acidification.

Embodiment 2

[0026] Embodiment 2, in volume is 8m 3 Add 5 tons of sodium sulfite solution into the dilution pot, and slowly put the alkali melt (reinforced alkali 900kg / batch of ingredients) generated by the alkali fusion reaction into the dilution pot, stir with the stirrer, and send the dilution at 95°C to the plate with compressed air In the frame filter press, liquid-solid separation is carried out, and then 400 liters of sodium sulfite solution at 80 °C is sent to the plate and frame filter press with compressed air to wash the filter cake, and then dried with compressed air to obtain 1300 kg of solid salt mixture. The main component of solid salt is sodium sulfite, which accounts for about 91.5%, water accounts for 1.6%, and the rest is sodium sulfate and sodium naphthalenesulfonate, etc. This solid salt can be used to produce lignin, liquid filtered out and di Boil the washing water and go to the acidification pot together for acidification.

Embodiment 3

[0027] Embodiment 3, except naphthalenesulfonic acid sodium salt mother liquor, sodium sulfite solution can be made diluent, after being provided with filter washing process, still can adopt two boiling washing water to make diluent, isolate sodium sulfite. In a volume of 8m 3 Add 4.5 tons of second-boiled washing water into the dilution pot, slowly put the alkali fusion product (reinforced alkali 900kg / batch of ingredients) generated by the alkali fusion reaction into the dilution pot, stir with the stirrer, and then send the diluted product at 85°C with compressed air Separation of liquid and solid in the plate and frame filter press, and then use compressed air to send 500 liters of sodium sulfite solution at 75 °C to the filter press to wash the filter cake, and dry it with compressed air to obtain 450 kg of solid sodium sulfite salt, the main component of which is sodium sulfite , accounted for 92%, water accounted for 1.3%, and the rest were sodium sulfate and sodium nap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com