Method for producing furol by extruding plant stalk

A technology of plant straw and furfural, applied in organic chemistry and other directions, can solve problems such as air pollution, achieve the effects of uniform acid mixing of materials, reduce production costs, and expand the scope of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

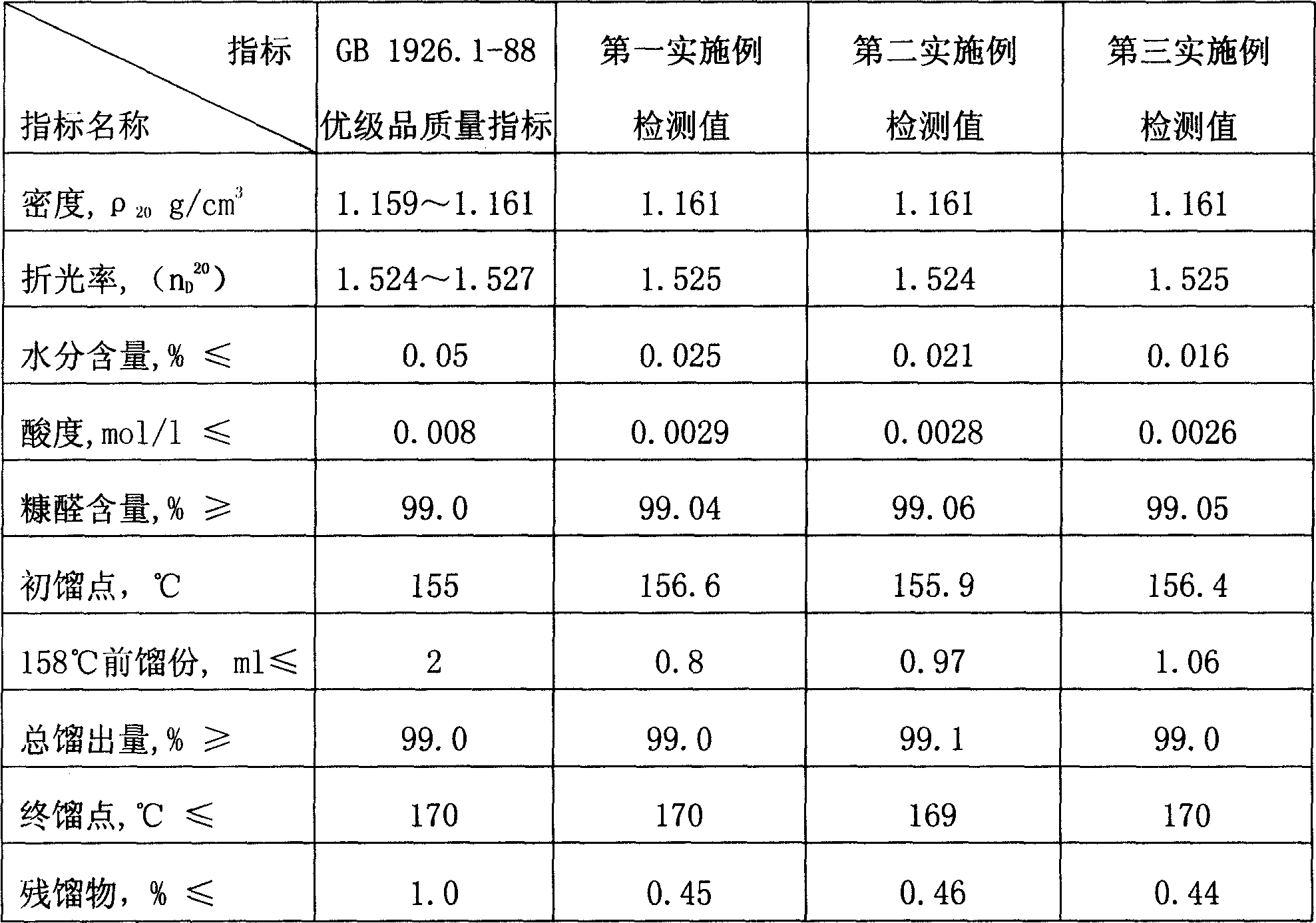

[0021] The raw material is corncobs air-dried in spring, and its water content is 23%. After the corncob is dedusted by a vibrating screen, it is crushed into 1-1.5cm corncob particles by a hammer mill, and then transported by the elevator to the acid mixing truck for acid mixing. The acid concentration is 5-10%, and the amount of acid used is kept at With a specific solid-to-liquid ratio, it is sent to the hydrolysis kettle through a belt conveyor. The volume of the hydrolysis kettle is 10 cubic meters, and the filling density of corncobs is 150-180kg / m 3 , using double tanks in series operation, after filling the hydrolysis tank, feed water vapor with a pressure of 0.45-0.75MPa, the hydrolysis temperature is 145-180°C, and the hydrolysis takes 2 hours to 4 hours. The furfural stock solution obtained by hydrolysis is introduced into the subsequent process, and the gross aldehyde is extracted, and the furfural is continuously refined to obtain commercial furfural. See Table 1...

Embodiment 2

[0023] The raw material is cut, pulverized and granulated corn stalk granules, and the water content of the granules is 27%. It is transported by the hoist to the acid mixing truck for acid mixing. The acid concentration is 5-20%, and the amount of acid used is kept at a specific solid-liquid ratio. It is sent to the hydrolysis tank through the belt conveyor, and the volume of the hydrolysis tank is 10 cubic meters. Rice, using double kettles in series operation, the packing density of corn stalk particles is 300-420kg / m 3 , After filling the hydrolysis kettle, feed water vapor with a pressure of 0.45-0.75MPa, and the hydrolysis temperature is 145-180°C, and the hydrolysis is performed for 2 hours to 4 hours. The furfural stock solution obtained by hydrolysis is introduced into the subsequent process, and the gross aldehyde is extracted, and the furfural is continuously refined to obtain commercial furfural. See Table 1 for details of the furfural quality detection indicators...

Embodiment 3

[0025] Cut corn stalks were used as raw materials, and the water content was 22%. After continuous acid mixing and extrusion equipment, the acid concentration is 5-10%, the amount of acid used is kept at a specific solid-to-liquid ratio, and it is continuously sent to the hydrolysis kettle. The volume of the hydrolysis kettle is 10 cubic meters, and a double kettle is used. Operated in series, the packing density of corn stalks after extrusion is 280-300kg / m 3 , After filling the hydrolysis kettle, feed water vapor with a pressure of 0.45-0.75MPa, and the hydrolysis temperature is 145-180°C, and the hydrolysis is performed for 2 hours to 4 hours. The furfural stock solution obtained by hydrolysis is introduced into the subsequent process, and the gross aldehyde is extracted, and the furfural is continuously refined to obtain commercial furfural. See Table 1 for details of the furfural quality detection indicators in this example. In this example, the yield of furfural is 5.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com