Combustible gas sensor preparing method

A gas sensor and semiconductor technology, applied in instruments, scientific instruments, measuring devices, etc., can solve problems such as fire and sensor explosion, and achieve the effects of good development prospects, low operating temperature and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

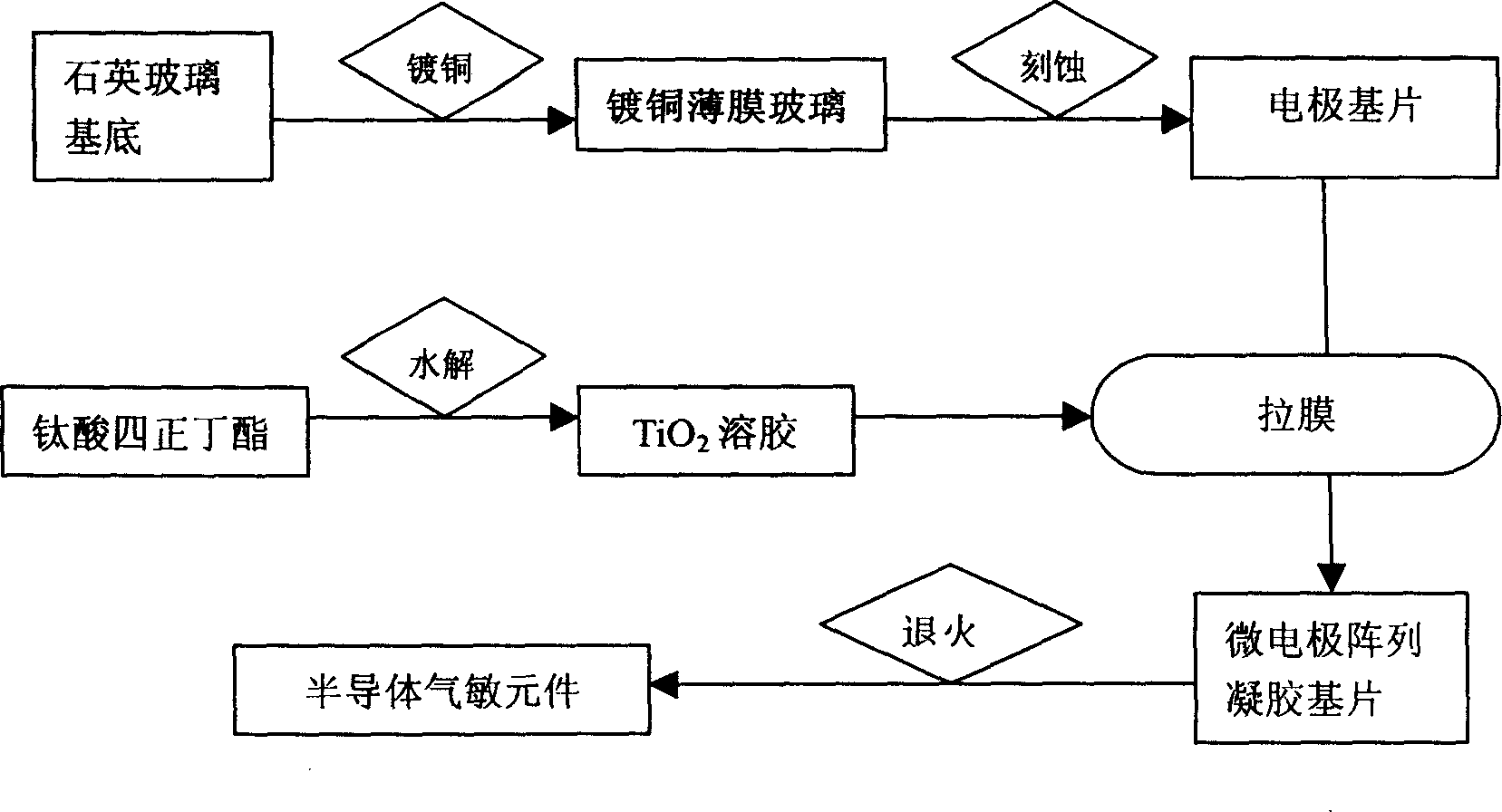

[0030] A kind of preparation method of combustible gas sensor, it comprises the steps: 1) the preparation of semiconductor gas sensor is (as figure 1 shown):

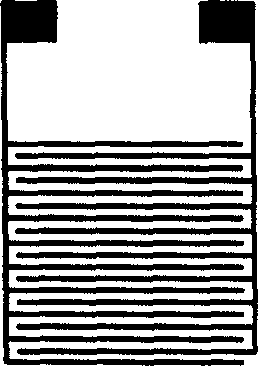

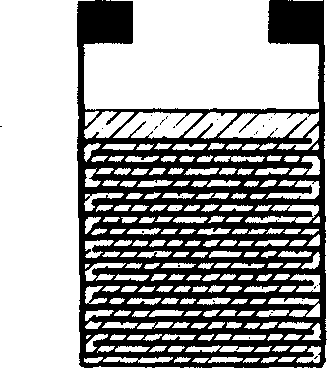

[0031] ①Using the magnetron sputtering coating method to plate a 3-10μm copper metal thin layer on a 1.5×3cm quartz glass substrate, and then using microfabrication technology, masking, photolithography, and corrosion methods to obtain an interdigitated layer on the glass substrate Microelectrode arrays (such as figure 2 shown), that is, the interdigitated microelectrode array electrode substrate; wherein the microelectrode line width is 3-10 μm, the gap width is 3-10 μm, the electrode line length is 10 mm, and the number of microelectrode pairs is more than 500 pairs;

[0032] ②Preparation of nano-TiO by organometallic alkoxide hydrolysis 2 Sol: add 13ml tetra-n-butyl titanate to 4ml isopropanol and mix evenly, slowly add the mixture dropwise to 120ml distilled water containing 2ml concentrated nitric acid, after th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com