Low cost high efficiency polyethylene conductive film and its preparation method

A technology of composite film and conductive film, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of high manufacturing cost and influence on popularization and application, and achieve the reduction of manufacturing cost, good electrical conductivity, The effect of better mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

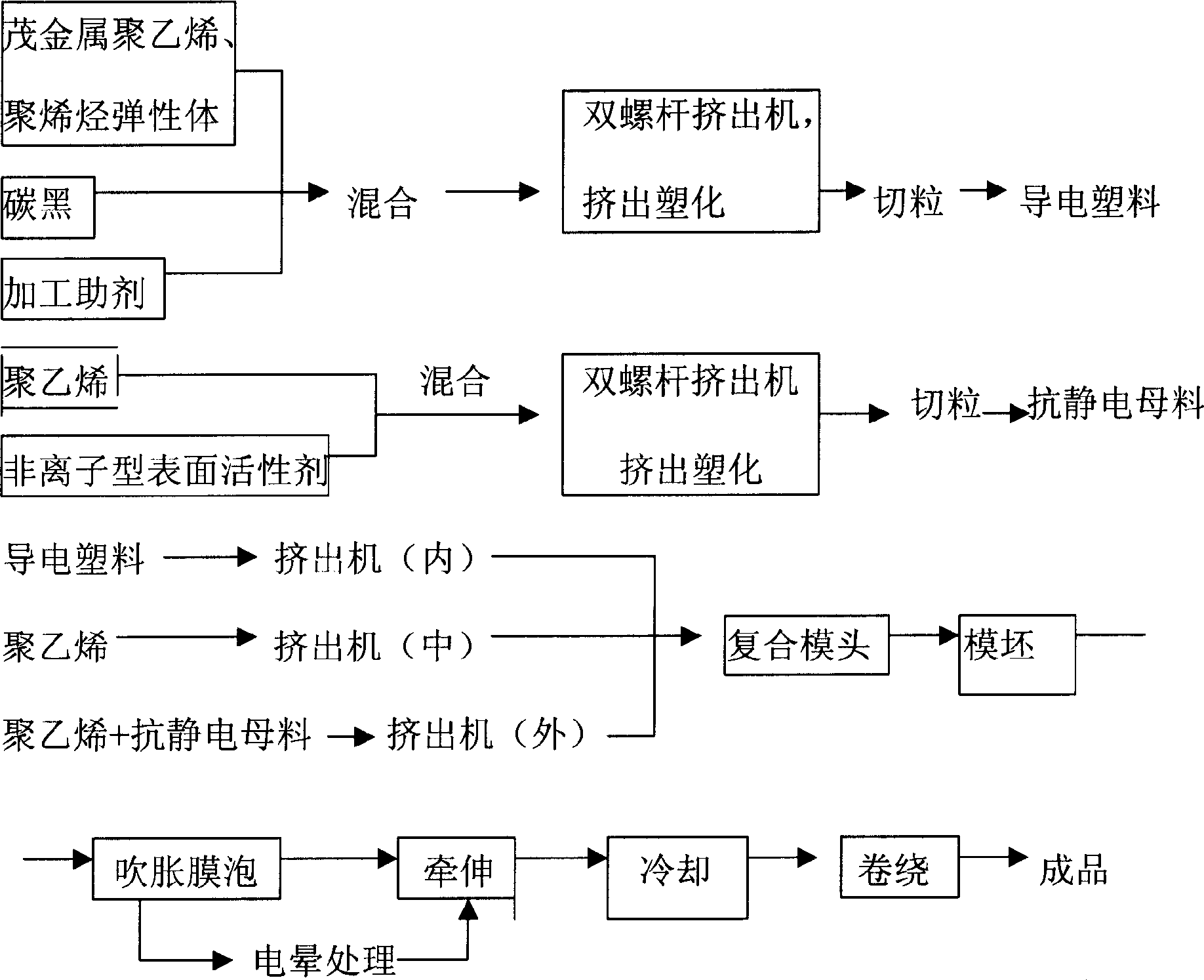

[0029] Put the metallocene polyethylene and special carbon black into the high-speed mixer according to the proportion of 70% and 30% by weight respectively, and fully stir for 15 minutes, unload the materials, add them into the co-rotating twin-screw extruder, and Mixing and plasticizing under the temperature of 180-200 ℃, after extrusion, it is pelletized by a hot pelletizer on the die surface, cut into oblate pellets, and cooled for later use. Or purchase polyethylene carbon black conductive special material with carbon black content of 30%.

[0030] The polyethylene and the nonionic surfactant antistatic agent are weighed in proportions of 80% and 15% by weight respectively, and 5% CaCO by weight is added 3 The powder is put into a high-speed mixer, fully stirred for 10 minutes, added into a co-rotating twin-screw extruder, mixed and extruded at a temperature of 130-160°C, and then pelletized by a hot pelletizer on the die surface after extrusion. Form into oblate pellets...

Embodiment 2

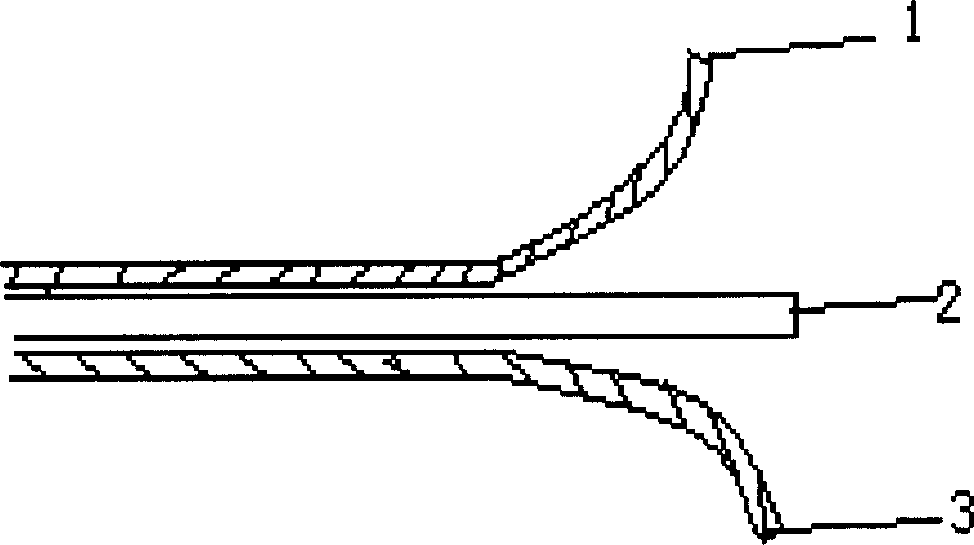

[0033] Select one set of three-layer co-extruded composite blown film production equipment (including three extruders), add polyethylene carbon black conductive special material into extruder I, and mix and extrude it at a temperature of 140-180°C; Add polyethylene and antistatic masterbatch into the mixer in proportions of 88%, 6%, and 6% by weight respectively, stir for 3 minutes, unload the materials, add to extruder II, and mix at 150-190°C Refining and plasticizing; add polyethylene, antistatic agent, and magnetic white mixed color masterbatch into the mixer in proportions of 86%, 6%, and 8% by weight respectively, stir for 3 minutes, unload the materials, and add them to the extruder III , and mixed and plasticized at a temperature of 150-190°C. The above three extruders respectively extrude the molten material into the three-layer co-extrusion multi-channel composite die head, and the die head heating temperature is 180-190°C; the melt is extruded into a film blank thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com