Composite catalyst for catalytic and oxidized treatment of three-phase waste water

A technology for wastewater treatment and catalytic oxidation, which is applied in the direction of oxidized water/sewage treatment, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. It can solve the long time of oxidation treatment, environmental protection impact, Deal with problems such as poor results, and achieve the effect of abundant raw materials, environmental protection, and mature manufacturing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

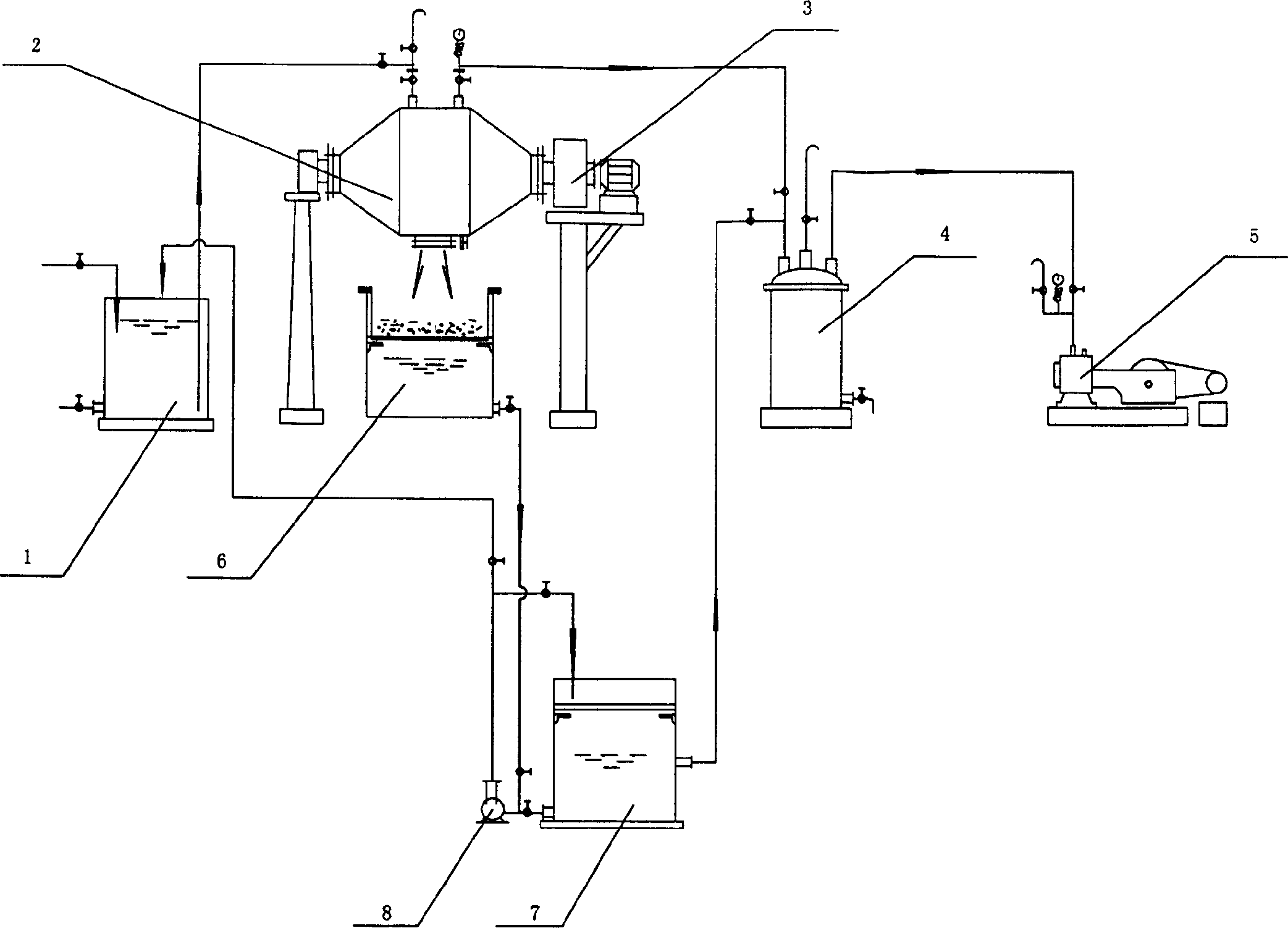

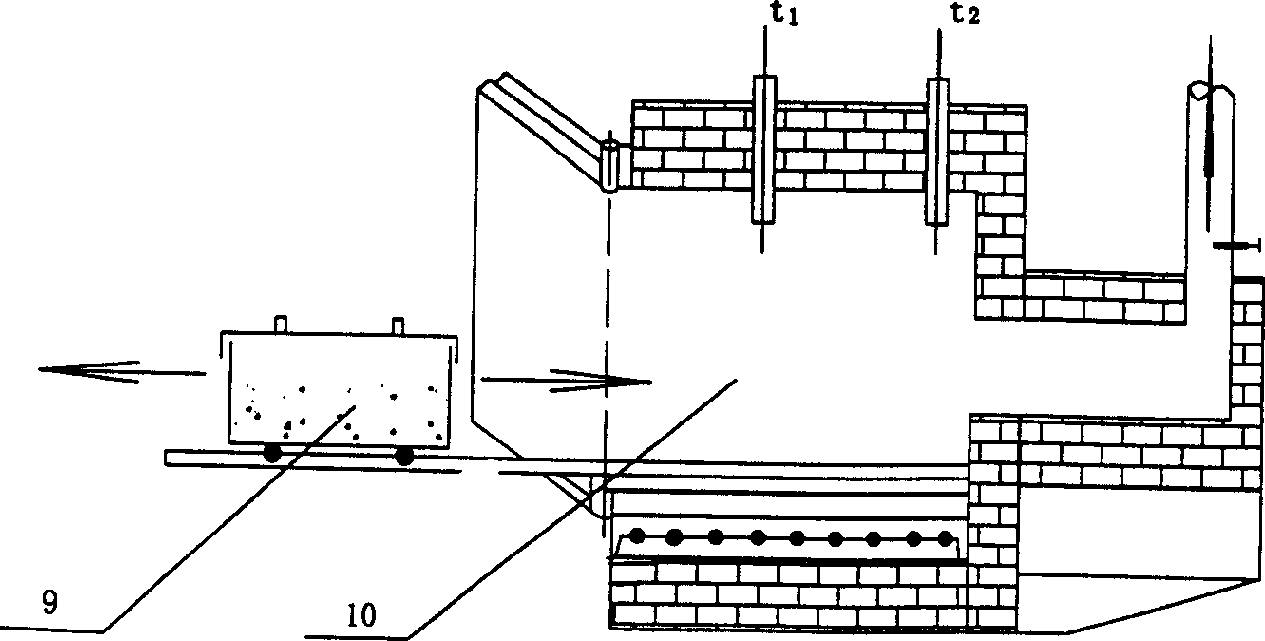

[0035] Such as figure 1 , 2 As shown, it is a composite catalyst process flow chart for three-phase catalytic oxidation treatment of wastewater, and the composite catalyst preparation system for three-phase catalytic oxidation treatment of wastewater consists of a juice preparation tank 1, a juice drum 2, a motor 3, a vacuum Box 4, vacuum pump 5, juice separation tank 6, juice filter tank 7, delivery pump 8, baking oven 9, catalyst activation furnace 10, juice preparation tank 1 is connected with juice drum 2 through a material pipe, and motor 3 Connect the juice extraction drum 2, the juice extraction drum 2 is connected with the vacuum box 4 through the vacuum tube, the vacuum pump 5 is connected with the vacuum box 4, the juice extraction liquid separation tank 6 is set directly below the juice extraction drum 2, and the juice extraction liquid filter tank is connected with the juice extraction liquid through the tube 7 is connected, and the dipping liquid filter tank 7 is...

Embodiment 2

[0043] First, 1.6 parts of cerium nitrate, 8.7 parts of copper nitrate, 18.9 parts of manganese nitrate, 0.6 part of zirconium nitrate, 0.6 part of cobalt nitrate, and 69.6 parts of tap water are prepared as a dipping liquid and placed in the dipping liquid preparation tank 1 for subsequent use.

Embodiment 1

[0045] Technical indicators of composite catalyst products for three-phase catalytic oxidation treatment of wastewater:

[0046] Appearance: Cylindrical particles Φ4×(50-60)mm

[0047] Moisture ≤30%

[0048] Strength ≥92.5%

[0049] Bulk density 540±10kg / m 3

[0050] Specific surface area (BET) 650-700m 3 / g

[0051] Pore volume 0.3648cm 3 / g

[0052] Average pore diameter 1.9556mm

[0053] Service life three years

[0054] When in use, high-concentration wastewater and oxidant (chlorine dioxide) are homogeneously mixed into the catalytic oxidation tower equipped with a composite catalyst supported by activated carbon, and an appropriate amount of air is introduced into the bottom of the tower to form a three-phase catalytic oxidation state, which is called normal temperature. Atmospheric pressure three-phase catalytic oxidation treatment of high concentration wastewater.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com