Solid dispersion of protopanaxadiol and preparation method thereof

A technology of protopanaxadiol and solid dispersion, which is applied in the field of medicine to achieve the effect of accelerating the dissolution rate and increasing the solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

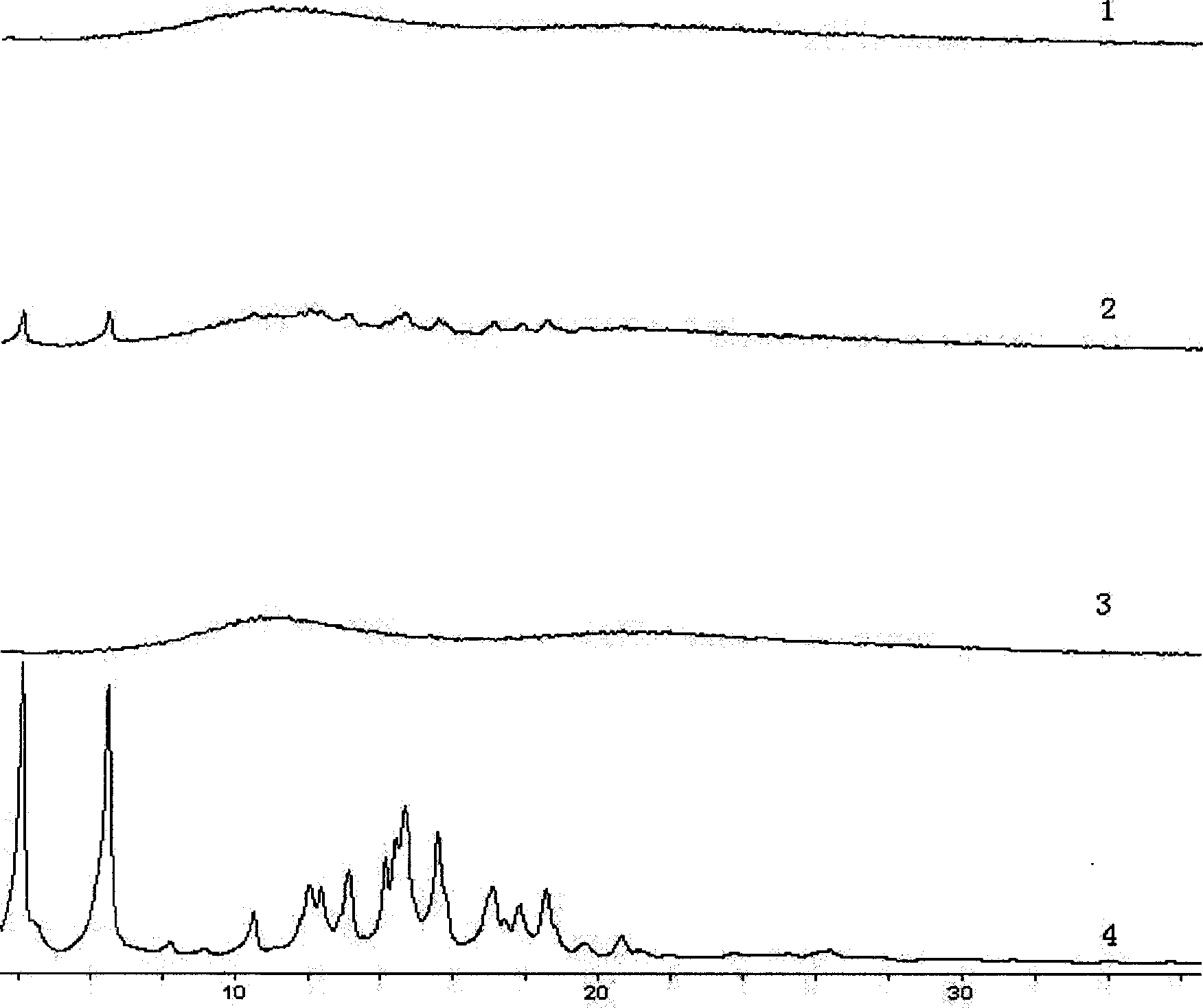

Image

Examples

Embodiment 1

[0048] Take 800mg of polyvinylpyrrolidone K30 and 200mg of 20(S)-protopanaxadiol, mix them evenly, put them in a mortar and grind them at a speed of 200rpm for 30min. Take it out and pass through a 100-mesh sieve. The solid dispersion of the invention has an in vitro cumulative dissolution rate of 40.5±2.3% (n=6) within 45 minutes.

Embodiment 2

[0050]Take 4000 mg of microcrystalline cellulose and 200 mg of 20(R)-protopanaxadiol, mix them evenly, and grind them in a mortar with a rotation speed of 100 rpm and a grinding time of 60 minutes. Take it out and pass through an 80-mesh sieve. The cumulative dissolution rate of the solid dispersion of the invention is 48.7±1.4% (n=6) in 45 minutes in vitro.

Embodiment 3

[0052] Take 1600mg of poloxamer-188 and 200mg of 20(S)-protopanaxadiol in an evaporating dish, heat and stir on a water bath at 60°C until completely melted, and then place the melt in an ice-salt bath under vigorous stirring. Cool to solid, place it in a desiccator at room temperature and dry for 2 days, take it out, grind it, and pass it through a 60-mesh sieve. The solid dispersion of the invention has an in vitro cumulative dissolution rate of 98.1±3.4% (n=6) within 45 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com