Radiation sensitive composition and color filter for forming coloration layer

A sensitive, radiation-based technology, applied to photosensitive materials used in optomechanical equipment, nonlinear optics, instruments, etc., can solve problems such as stripes, adhesion, and longer time in the direction of travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0224] Process 15 parts by weight of the mixture of C.I. Pigment Red 254 / C.I. Pigment Red 177=80 / 20 (weight ratio) as (A) coloring agent, 4 parts by weight (converted into solid content) as Disperbyk-2001 of dispersant by ball mill 6 parts by weight of methacrylic acid / N-phenylmaleimide / styrene / benzyl methacrylate copolymer as (B) alkali-soluble resin (copolymerization weight ratio=20 / 30 / 20 / 30, Mw =9,500, Mn=5,000) and 75 parts by weight of propylene glycol monomethyl ether acetate as a solvent for (E) to prepare a predispersion (R1).

[0225] Next, mix 100 parts by weight of the pre-dispersion (R1), 5 parts by weight of methacrylic acid / succinic acid mono(2-methacryloyloxyethyl) ester / N-phenyl Maleimide / styrene / benzyl methacrylate copolymer (copolymerization weight ratio=25 / 10 / 30 / 20 / 15, Mw=12,000, Mn=6,500), 10 parts by weight as (C) multifunctional dipentaerythritol hexaacrylate as a neutral monomer, 5 parts by weight of 2-methyl-(4-methylthiophenyl)-2-morpholino-1-acetone-...

Embodiment 2

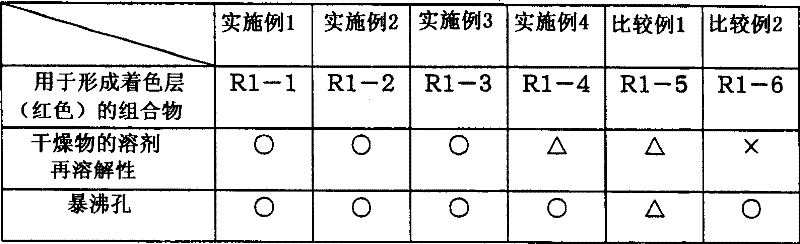

[0239] In Example 1, except relative to 100 parts by weight of the predispersion liquid (R1), the added (E) solvent was changed to 50 parts by weight of dipropylene glycol dimethyl ether and 125 parts by weight of 3-ethoxy ethyl propionate Except for the ester, the same operation as in Example 1 was performed to prepare and evaluate a composition (R1-2) for forming a colored layer. The evaluation results are shown in Table 1.

Embodiment 3

[0241] In Example 1, except relative to 100 parts by weight of the predispersion liquid (R1), the added (E) solvent was changed to 50 parts by weight of dipropylene glycol dimethyl ether, 50 parts by weight of propylene glycol monomethyl ether acetate, Except 25 parts by weight of diethylene glycol methyl ethyl ether and 3-methoxybutyl acetate of 50 parts by weight, carry out identical operation with embodiment 1, prepare the composition (R1-3) that is used to form colored layer, and Make an evaluation. The evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com