Optical semiconductor device and method of manufacture thereof

An optical semiconductor and device technology, which is applied in the fields of semiconductor lasers, optical head manufacturing, and laser parts, etc., can solve the problems of increasing the area of the light-receiving element substrate 103, increasing the working current, and reducing the light output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

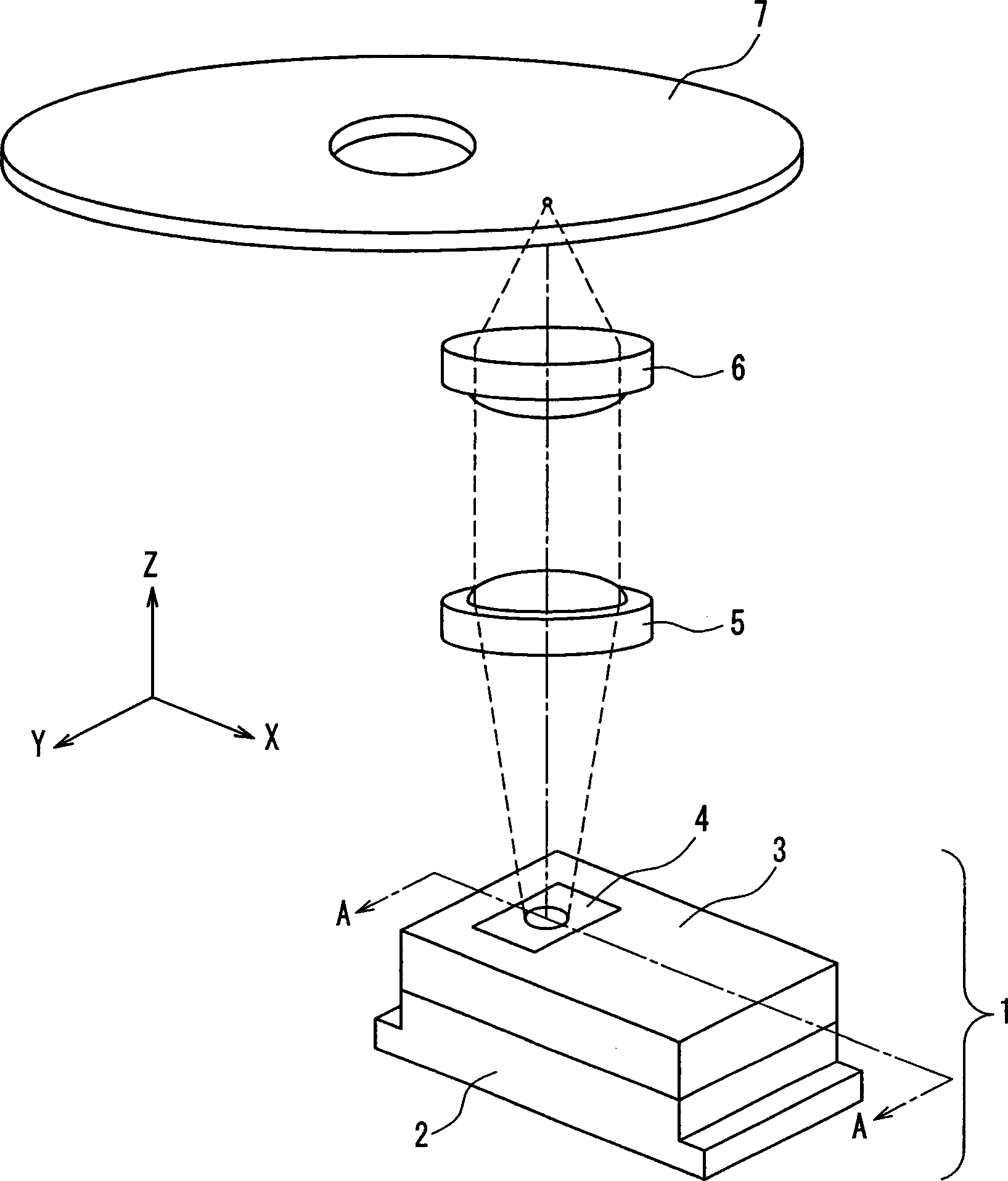

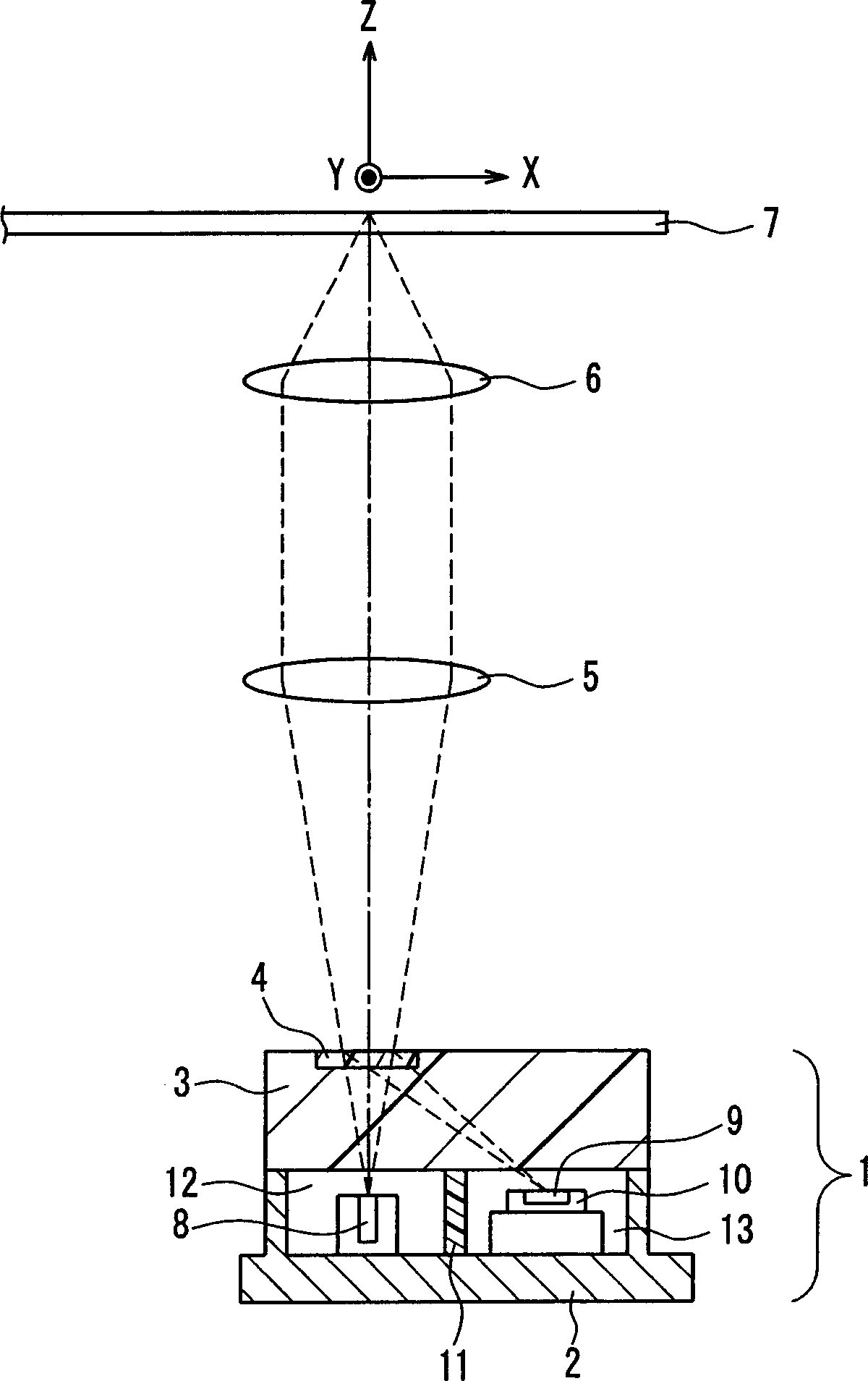

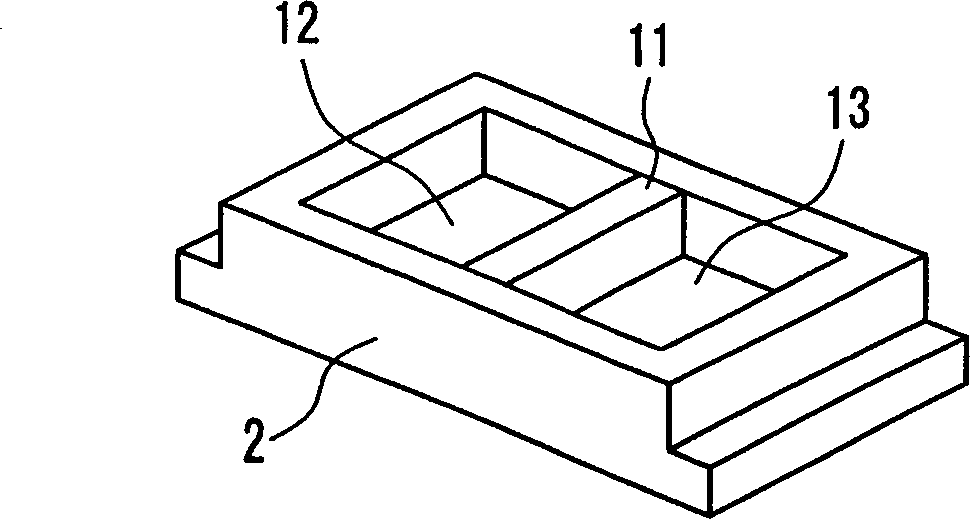

[0054] figure 1 It is a perspective view showing a disk playback device equipped with an optical semiconductor device according to Embodiment 1 as an example. Figure 2A Yes figure 1 The side view of the optical disc playback device shown, which only shows the optical semiconductor device in section ( figure 1 A-A profile in ). Figure 2B is a perspective view of the package.

[0055] exist figure 1 Among them, the optical semiconductor device 1 is constituted as an integrated structure of a package 2 and an optical module 3, wherein the package 2 has a semiconductor laser element and a light receiving element inside, and a hologram element 4 is formed in the optical module 3. The divergent light beam emitted from the semiconductor laser element is emitted from the hologram element 4 , becomes parallel light through the collimator lens 5 , and is concentrated on the information surface of the optical disc 7 through the objective lens 6 .

[0056] The light beam reflec...

Embodiment approach 2

[0070] Figure 5A It is a sectional view showing the structure of the optical semiconductor device of Embodiment 2. Figure 5B is a perspective view of the package in the device. In addition, since the configuration of the optical system other than the optical semiconductor device 1 and figure 1 are the same, so the illustration is omitted.

[0071] First, the operation of a disc playback device equipped with the optical semiconductor device of Embodiment 2 will be described.

[0072] exist Figure 5A Among them, the divergent light beam emitted from the semiconductor laser element 8 transmits the space separation element 20 and the hologram element 4 made of light-transmitting materials arranged on the exit optical axis of the semiconductor laser element, and passes through the collimator lens 5 (refer to figure 1 ) becomes parallel light, passes through the objective lens 6 (reference figure 1 ) to focus the light on disc 7 (ref. figure 1 )superior.

[0073] In ad...

Embodiment approach 3

[0089] Figure 12 It is a sectional view showing the structure of the optical semiconductor device of Embodiment 3. In addition, since the structure of the optical system other than the optical semiconductor device 1 and figure 1 are the same, so the illustration is omitted.

[0090] First, the operation of a disc playback device equipped with an optical semiconductor device will be described.

[0091] exist Figure 12 In this case, the divergent light beam emitted horizontally from the semiconductor laser element 8 is reflected by the reflective surface 15a of the first reflective element 15 inclined at 45° with respect to the outgoing optical axis, thereby changing the optical path by 90°. Afterwards, by collimating lens 5 (reference figure 1 ) becomes parallel light, which passes through the objective lens 6 (reference figure 1 ) to focus the light on disc 7 (ref. figure 1 )superior.

[0092] The reflected light beam from the optical disc 7 is incident on such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com