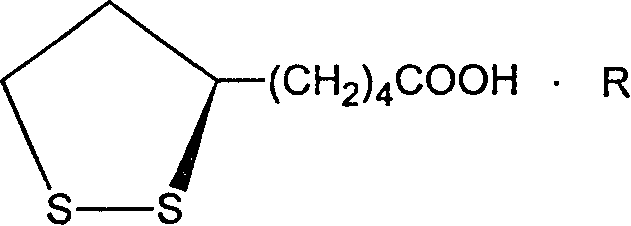

Dextro lipoic amidate and its prepn

A technology of d-lipoic acid and amino acid salt, which is applied in the directions of pharmaceutical formulations, medical preparations containing active ingredients, digestive system, etc., can solve the problems of d-lipoic acid's easy polymerization, thermal stability, insolubility in water, and the like, and achieves good results. Water-soluble, the effect of increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

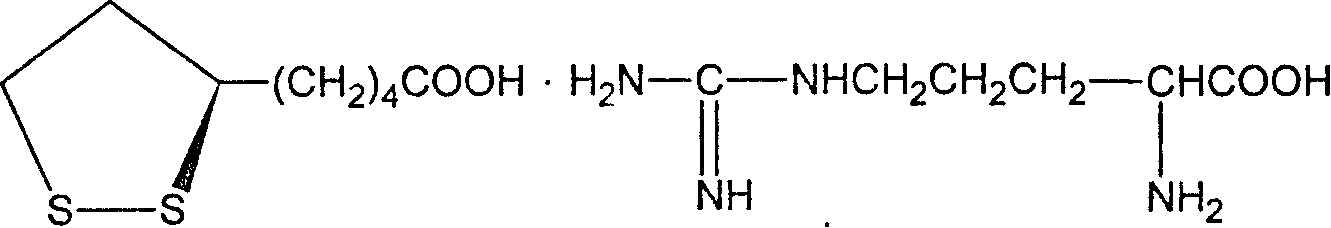

[0036] Embodiment 1: Preparation of D-lipoic acid arginine salt

[0037] raw material name

Feeding amount

D-lipoic acid

L-Arginine

Absolute ethanol

100g

87g

600ml

1

1.05

[0038] operate:

[0039] Put D-lipoic acid, L-arginine, and absolute ethanol into a 1000ml three-necked reaction flask, stir, heat to reflux, and after 2 hours of reflux reaction, evaporate 3 / 4 of the solvent under reduced pressure, and cool the solution at 5-10°C Crystallized, filtered, and dried at 80°C for 6 hours to obtain 172 g of light yellow crystalline solid, yield 94.0%, mp 200-203°C.

Embodiment 2

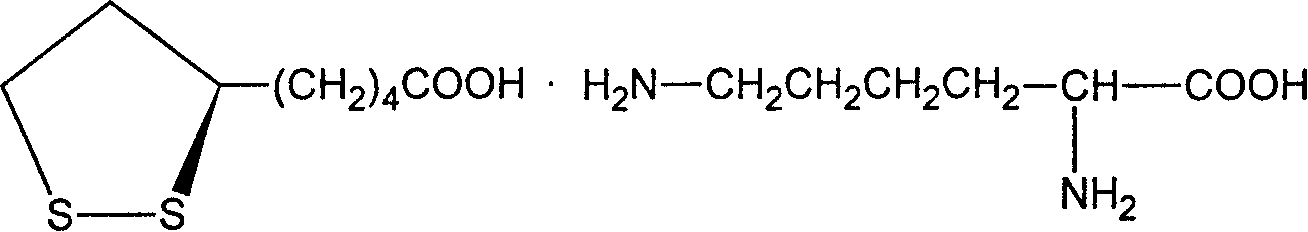

[0040] Embodiment 2: the preparation of D-lipoic acid lysine salt

[0041] raw material name

Feeding amount

D-lipoic acid

L-Lysine

100g

71g

1

1.0

Ethanol (95%)

600ml

[0042] operate:

[0043] Put D-lipoic acid, L-lysine, and ethanol into a 1000ml three-necked reaction flask, stir, heat to reflux, and after 2 hours of reflux reaction, evaporate 3 / 4 of the solvent under reduced pressure, and cool the solution at 5-10°C to crystallize. After filtration, the crystals were dried at 80°C for 6 hours to obtain 161 g of light yellow crystalline solids, yield 94.2%, mp 195-198°C.

Embodiment 3

[0044] Embodiment 3: Preparation of D-lipoic acid ornithine salt

[0045] raw material name

Feeding amount

D-lipoic acid

100g

70g

500ml

1

1.1

[0046] operate:

[0047] Put D-lipoic acid, ornithine, and methanol into a 1000ml three-neck reaction flask, stir, heat to reflux, and after 2 hours of reflux reaction, evaporate 3 / 4 of the solvent under reduced pressure, cool the solution at 5-10°C to crystallize, filter, The crystals were dried at 80°C for 6 hours to obtain 155 g of a light yellow crystalline solid, yield 94.5%, mp 185-187°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com