Carbon monoxide and methane integral optical fiber sensing measuring system

A carbon monoxide and optical fiber sensing technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of low precision, difficult adjustment, many sensors and cables, etc., to reduce system cost, stable chemical properties, and good electrical insulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

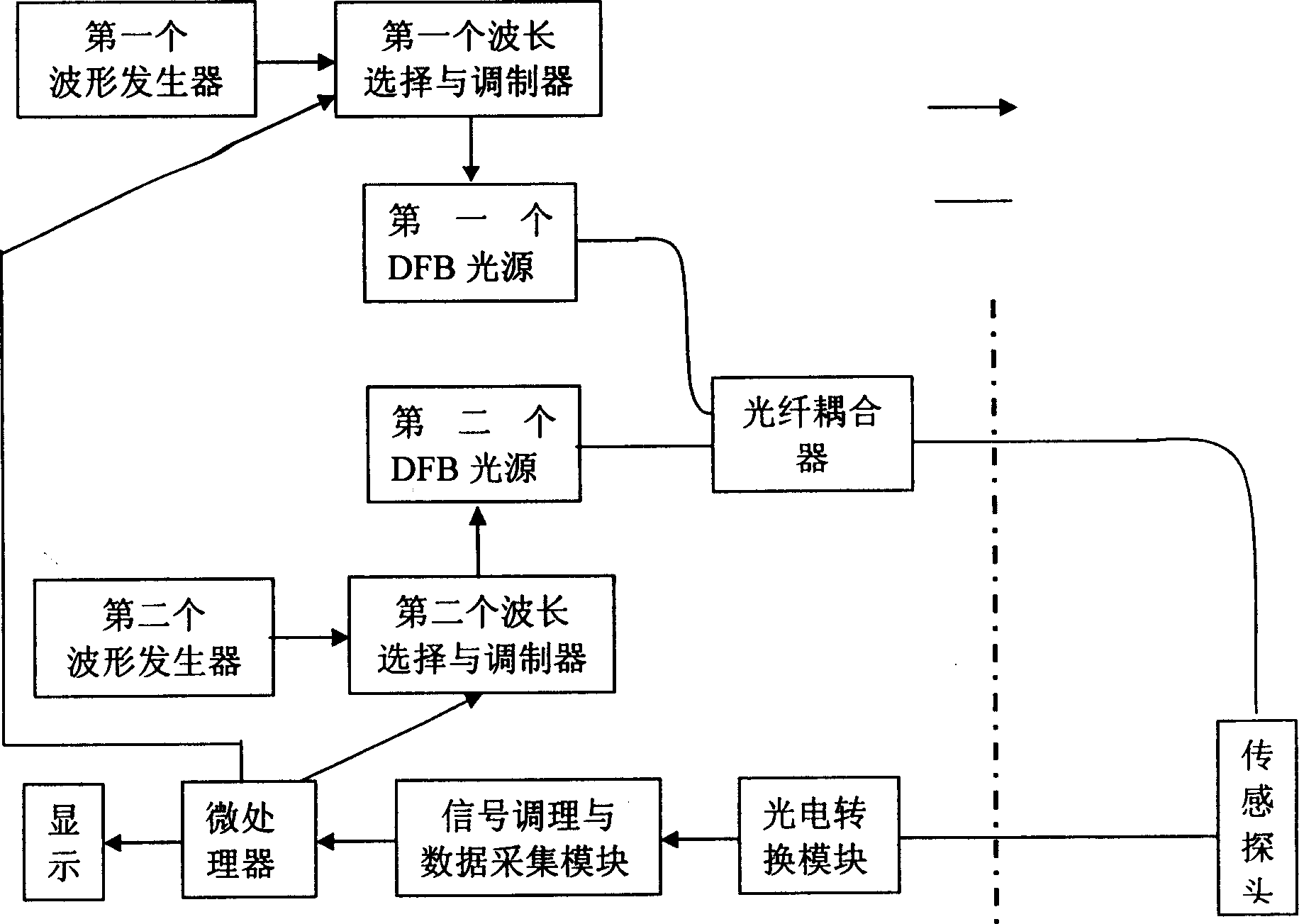

[0016] As shown in the figure, the carbon monoxide and methane integrated optical fiber sensing and measurement system mainly includes the first DFB laser source, the second DFB laser source, the first waveform generator, the second waveform generator, and the first wavelength selection and modulator, second wavelength selective and modulator, fiber optic coupler, sensing probe, photoelectric conversion module, signal conditioning and data acquisition module, and microprocessor. It is characterized in that the connection mode is as follows: the first waveform generator acts on the first wavelength selection and modulator, the first wavelength selection and modulator controls the first DFB laser source, and the first DFB laser source is coupled through an optical fiber connection One input of the device; the second waveform generator acts on the second wavelength selection and modulator, the second wavelength selection and modulator controls the second DFB laser source, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com