Petrol additive

A gasoline additive and solvent technology, applied in the field of gasoline additives, can solve the problems of high cost of additives, difficulty in popularization and application, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

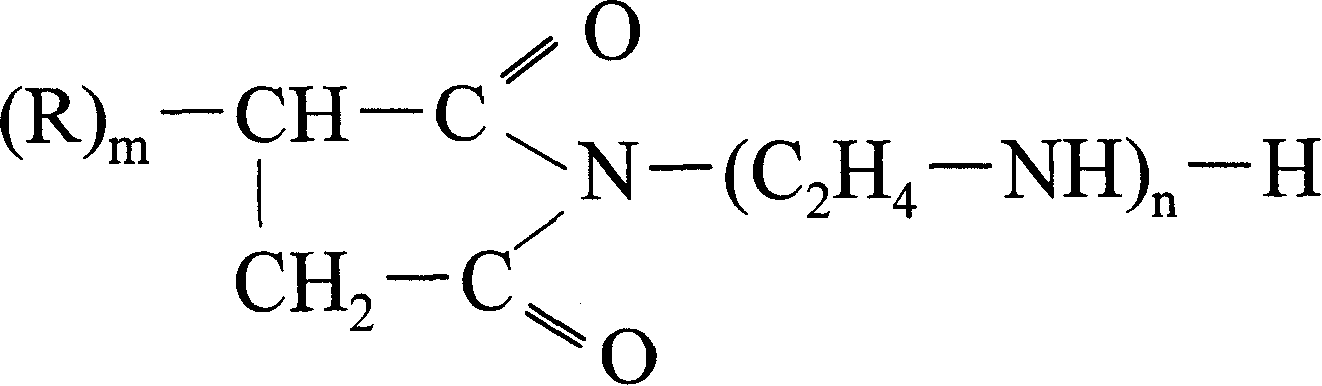

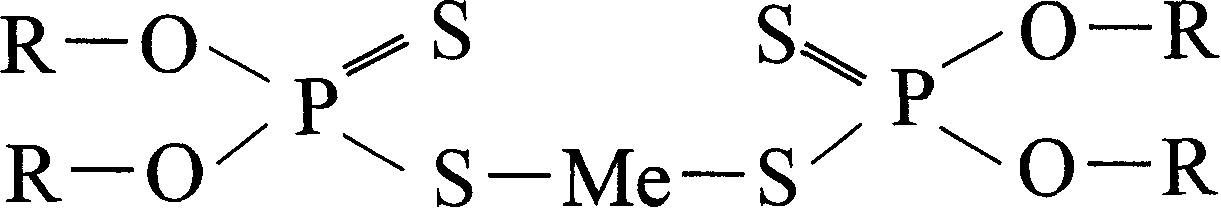

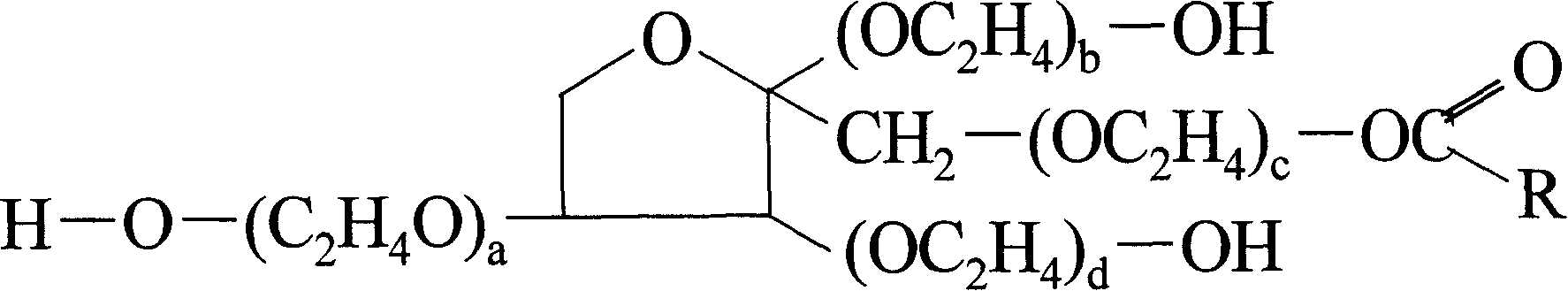

[0037] Weigh 4 grams of alkyl polyoxyethylene polyoxypropylene ether (R is an alkyl group with a carbon number of 12-14, m=4, n=7, R' is -H), 2 grams of polyol fatty acid ester polyoxygen Vinyl ether (R is an alkyl group with 17 carbons, a+b+c+d=18-22) is added to a reactor containing 20 grams of diesel oil, and after stirring for 5 minutes, continue to add 50 grams of polyisobutylene succinyl Imine, 24 grams of zinc diisooctyldithiophosphate, heated the feed solution to 30-40° C., and stirred for 10 minutes to prepare the additive (1), whose composition is listed in Table 1.

[0038] Add 5 grams of above-mentioned additives (1) in 1 kilogram of pure gasoline. Compared with pure gasoline under the same conditions of use (same engine, same mileage, same engine speed or same vehicle speed), the fuel saving rate of gasoline with additives is 9.2%, and the reduction of pollutants in exhaust gas is 38.5% respectively. , HC decreased by 45.0%.

Embodiment 2

[0040] Weigh 4 grams of alkyl polyoxyethylene polyoxypropylene ether (R is an alkyl group with a carbon number of 12-14, m=4, n=7, R' is -H), 2 grams of polyol fatty acid ester polyoxygen Vinyl ether (R is an alkyl group with 17 carbons, a+b+c+d=18-22) is added to a container containing 30 grams of diesel oil, and after stirring for 5 minutes, continue to add 45 grams of polyisobutylene succinyl Amine, 19 grams of zinc diisooctyldithiophosphate, the feed solution was heated to 30-40 ° C, and then stirred for 10 minutes to prepare the additive (2), the composition of which is listed in Table 1.

[0041] Add 5 grams of above-mentioned additives (2) in 1 kilogram of pure gasoline. Compared with pure gasoline under the same conditions of use (same engine, same mileage, same engine speed or same vehicle speed), the fuel saving rate of gasoline with additives is 5.2%, and the reduction of pollutants in exhaust gas is 23.6% respectively. , HC decreased by 29.8%.

Embodiment 3

[0043]Weigh 50 grams of polyisobutylene succinimide and 24 grams of zinc diisooctyl dithiophosphate, add them into a container containing 26 grams of diesel oil, heat the feed solution to 30-40 ° C, and stir for 10 minutes to prepare Obtain additive (3), its composition is listed in Table 1.

[0044] Add 5 grams of above-mentioned additive (3) in 1 kilogram of pure gasoline. Compared with pure gasoline under the same conditions of use (same engine, same mileage, same engine speed or same vehicle speed), the fuel saving rate of gasoline with additives is 5.0%, and the reduction of pollutants in exhaust gas is 23.0% respectively. , HC decreased by 29.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com