Antimicrobial composite material

An anti-microbial and biocide technology, applied in metal material coating technology, biocides, animal repellants, etc., can solve the problems of large amount of reagents, cannot be used in medical products, cannot exclude cytotoxicity, etc. The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: prepare coating material of the present invention

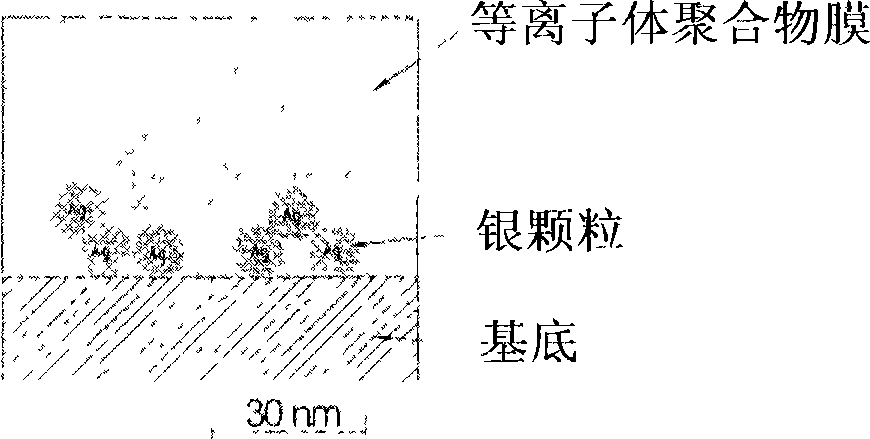

[0049] In a first coating step, the solid substrate to be coated with the antimicrobial and non-cytotoxic coating material of the present invention is coated with porous nanoscale silver. This is achieved by vaporizing metallic silver in an inert gas atmosphere, such as argon, at an operating pressure of about 10 mbar. A silver coating (biocide layer) is produced on this substrate, said coating containing single silver particles or chains of silver particles. The average particle size of the silver particles is 10-20nm. The thickness of the silver coating (biocide layer) is about 20 nm.

[0050] In a second coating step, a plasma polymer layer containing hexamethyldisiloxane (HMDSO) as precursor is applied. Made of 95% O at a working pressure of 0.07 mbar 2 Plasma polymerization was performed with a working gas composed of 5% HMDSO. After 45 seconds of plasma polymerization under the stated condition...

Embodiment 2

[0052] Example 2: Preparation of a coating material according to the invention using an adhesion-promoting layer

[0053] In a first step, the substrate to be coated with the coating material of the invention is coated with a titanium dioxide film by plasma polymerization. The precursor used is titanium tetraisopropoxide mixed with oxygen. The polymerization time was 5 minutes. Forms 25nm thick TiO with good adhesion 2 membrane.

[0054] In the second coating step, in ultra-high vacuum, a thin metallic silver layer was deposited on the TiO 2 film. During deposition, the process pressure was 10 -4 millibar. Evaporation is carried out so that a 10-20 nm thick silver layer (biocide layer) is deposited on the TiO 2 film.

[0055] In a third coating step, a plasma polymer film (transport control layer) is coated on the silver layer. Plasma polymerization was performed as described in Example 1. A 45 nm thick layer of highly hydrophilic plasma polymer was formed.

[0056]...

Embodiment 3

[0057] Example 3: Application of a Transport Control Layer to a Biocidal Solid

[0058] Using the plasma polymerization method described in Example 1, a plasma polymer film was deposited on the copper solid layer as a transport control layer. Compared with Example 1, the plasma coating process was performed for 450 seconds. The transport control layer thus produced had a thickness of 100 nm. The resulting coating material according to the invention, the biocide layer is an initial layer of solid copper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com