Carbon-gas gel powder and its preparation

A carbon airgel and powder technology, which is applied in the field of airgel powder preparation, can solve problems such as insecurity, and achieve the effects of small pore size, high stability, and elimination of local uneven concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

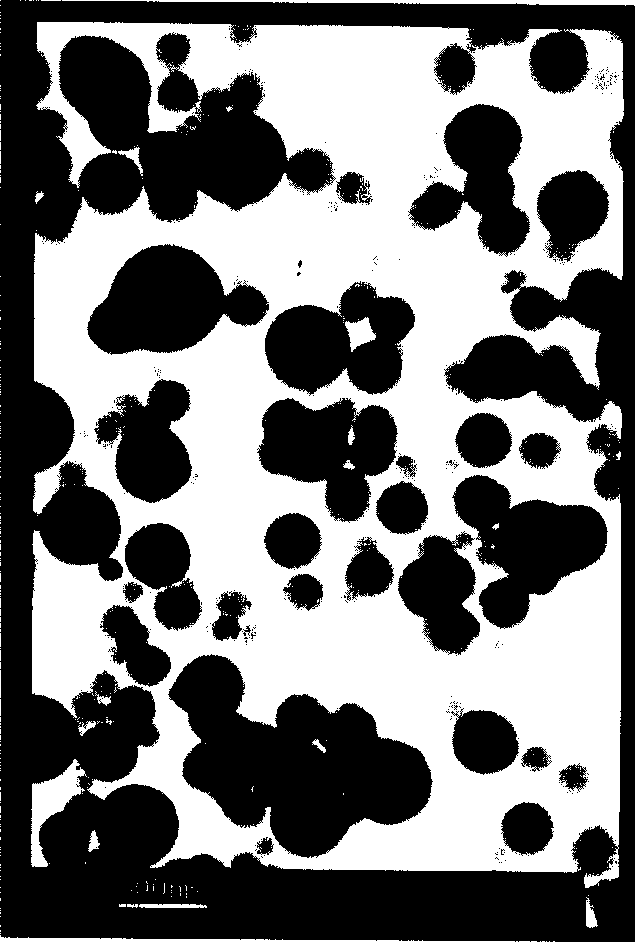

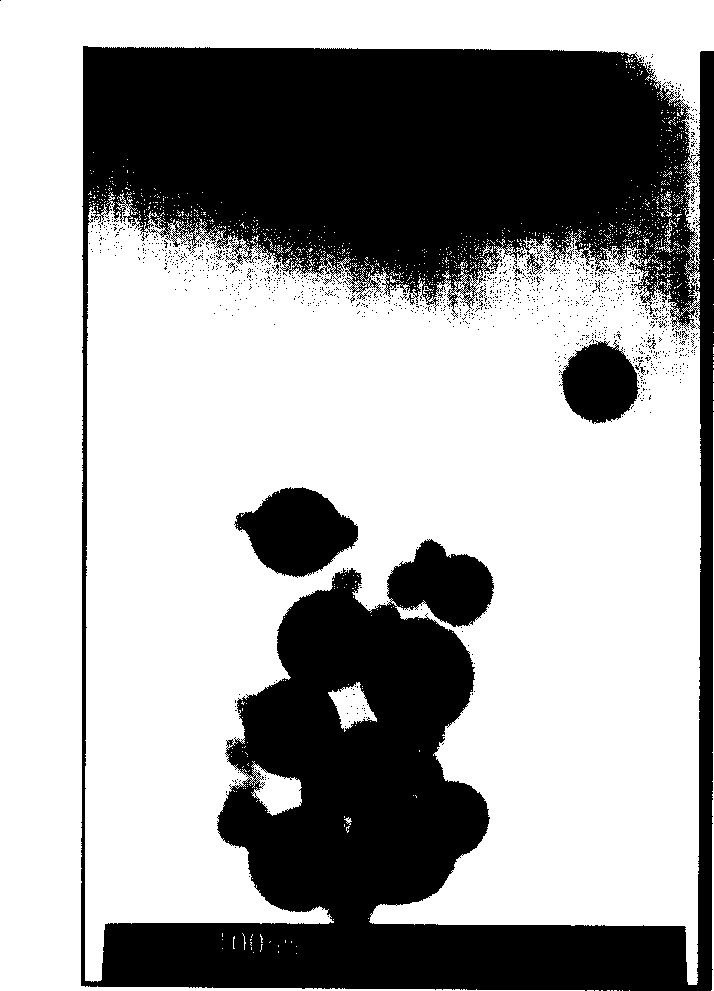

[0023] Sodium carbonate is used as a catalyst, the aqueous solution of resorcinol and formaldehyde with a concentration of 5% is used as a reaction solution 5ml, 250ml of silicone oil is used as a dispersant, ultrasonication is performed at a low temperature of 5°C for 1h, the temperature is raised to 10°C, and ultrasonication is performed for 3h, and then the temperature is raised to Continue to sonicate for 3 hours at 20°C. The nanoparticle product and the oil phase were separated by centrifugation to obtain a yellow muddy product. The sludge product was washed repeatedly with n-hexane and centrifuged. Finally, wash with ethanol and centrifuge. The centrifugation parameters are: 10000 rpm for 10 minutes to obtain a yellow ethanol suspension, which is supercritically dried with ethanol to obtain resorcinol-formaldehyde organic airgel powder. The temperature is 150 ℃ vacuum degassing, in N 2 Under protection, the temperature was raised at 1.5°C / min to 1050°C for 5 hours to o...

Embodiment 2

[0025] Repeat the method of Example 1, but the experimental conditions are 2 hours of sonication at a low temperature of 4.5°C, 3 hours of sonication at 8°C, and 3 hours of sonication at 15°C. The particle size distribution of the final product is between 50nm and 500nm, the pore size distribution is between 0.5nm and 10nm, and the specific surface area is 960m 2 / g.

Embodiment 3

[0027] Repeat the method of Example 1, but the concentration is 10% of the aqueous solution of resorcinol and formaldehyde as the reaction liquid, silicone oil as the dispersant, ultrasonication at 5°C for 1 hour, heating to 8°C for 3 hours, and then heating to 15°C. Continue to sonicate at ℃ for 3h. The temperature is 150°C, vacuum degassing, under the protection of Ar, the temperature is raised to 600°C at 1.5°C / min for 5 hours, the particle size distribution of the final product is 50nm-500nm, the pore size distribution is 0.5nm-10nm, and the specific surface area is 840m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com