Composite heating thermal-insulating pressing riser bush

A technology for pressurizing risers and riser sleeves, applied in the field of riser sleeves for casting, can solve the problems of shrinkage, shrinkage porosity, casting dispersion, etc., and achieve the effects of improving density, low cost and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

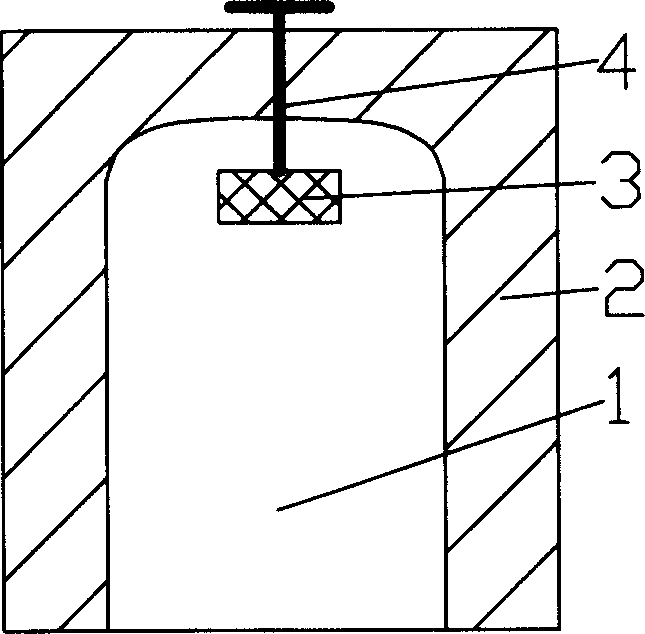

[0021] Such as figure 1 Shown is a schematic diagram of the structure of the present invention: 1 riser cover, 2 heat insulating material, 3 heating block, 4 hook. The main feature is that a hook 4 is fixed at the center of the top of the riser sleeve 1, and the heating and gas generating block 3 is fixed in the riser sleeve through the hook 4.

[0022] The thermal insulation material 2 is composed of hollow microsphere powder, fly ash, perlite, bentonite and water glass.

[0023] The heating and gas generating block 3 is formed by pressing the heating material aluminum powder, the oxygen supply material iron concentrate powder, the ignition material sodium nitrate, the reaction activation material sodium fluoride and the binding agent, and the volume of the heating and gas generating block can be as required. Varies for feeding castings.

Embodiment 2

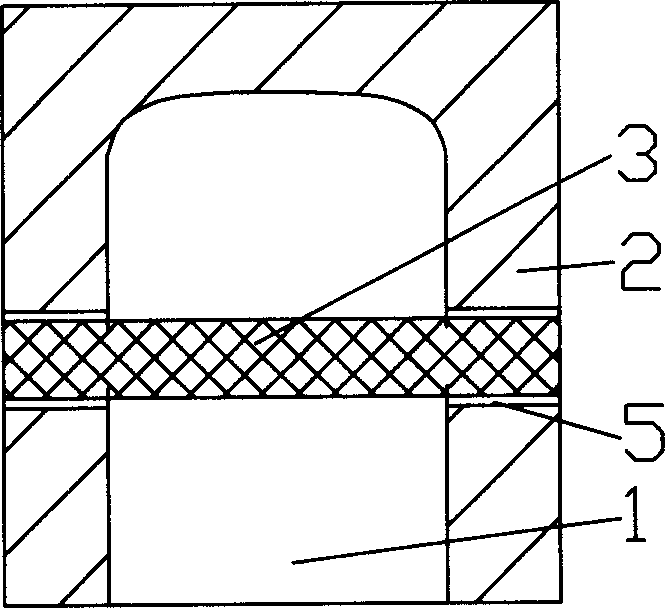

[0025] Such as figure 2 As shown, it is another structural schematic diagram of the present invention: 1 riser sleeve, 2 insulation material, 3 heating and gas generating block, 5 through hole. The inner wall of the riser sleeve 1 is provided with two opposite through holes 5 , and the heating and gas generating block 3 is fixed on the two through holes 5 .

[0026] The material composition of the heat-insulating material 2 and the heat-generating and gas-generating block 3 is basically the same as that of Example 1.

Embodiment 3

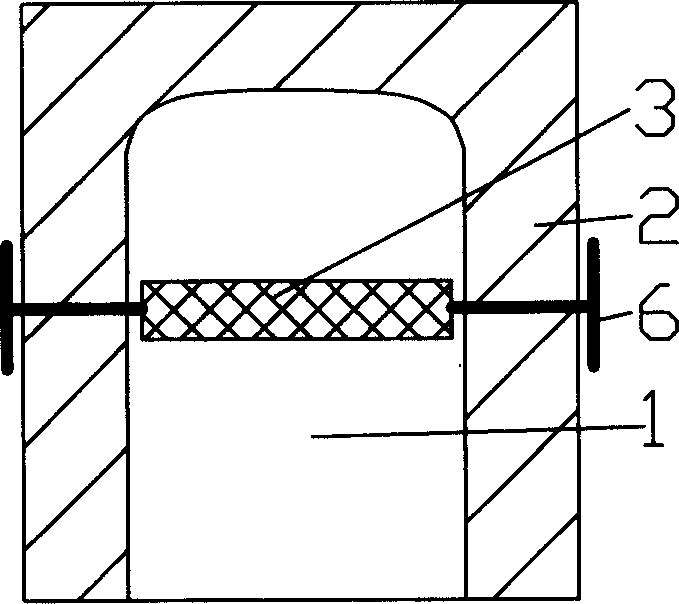

[0028] Such as image 3 As shown, it is another structural schematic diagram of the present invention: 1 riser cover, 2 insulation material, 3 heating and gas generating block, 6 pins. The inner wall of the riser sleeve 1 is provided with two opposite pins 6 , and the heating and gas generating block 3 is fixed on the inner wall of the riser sleeve by the pins 6 .

[0029] The material composition of the heat-insulating material 2 and the heat-generating and gas-generating block 3 is basically the same as that of Example 1.

[0030] Riser category

[0031] The results of this test show that: compared with common heat-preserving and pressurized riser sleeves on the market, the solidification time of the riser sleeves of Embodiment 1, Embodiment 2, and Embodiment 3 of the present invention is respectively prolonged by 21.3%, 20.4%, and 22.1%. The feeding efficiency increased by 36.4%, 34.5%, and 38.2%, respectively, and the shrinkage porosity and shrinkage defect rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com