Preparation method of high density polyethylene communication cable insulating material

A high-density polyethylene and communication cable technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of high catalyst costs, product performance limitations, and difficult development, etc., to improve processing performance and processing fluidity The effect of improvement, uniformity and overall performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

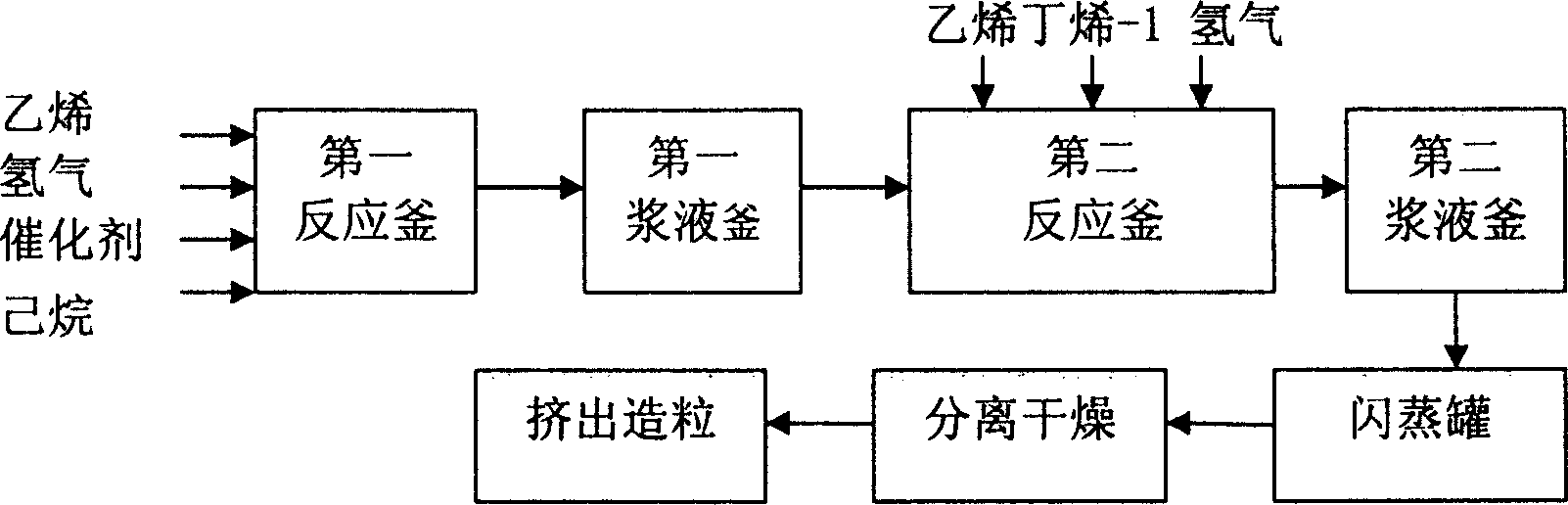

Embodiment 1

[0040] According to the manufacturing method of bimodal high-density polyethylene communication cable insulating material involved in the present invention, on the high-density polyethylene device of Mitsui process, under the action of Ziegler-Natta catalyst (titanium trichloride and aluminum alkyl), bimodal The slurry polymerization tanks are connected in series to carry out the polymerization reaction. Add catalyst in the first reactor, and only add ethylene hydrogen without adding comonomer butene-1, react for 2 hours, the polymer produced is low molecular weight polyethylene homopolymer; no catalyst is added in the second reactor , and adding ethylene, hydrogen and comonomer butene-1, so that the comonomer butene-1 is polymerized to the high molecular weight polyethylene molecular chain in the product, and reacted for 2 hours, and the polymer produced is a high molecular weight polyethylene copolymer. The specific production process control parameters of the two reactors a...

Embodiment 2

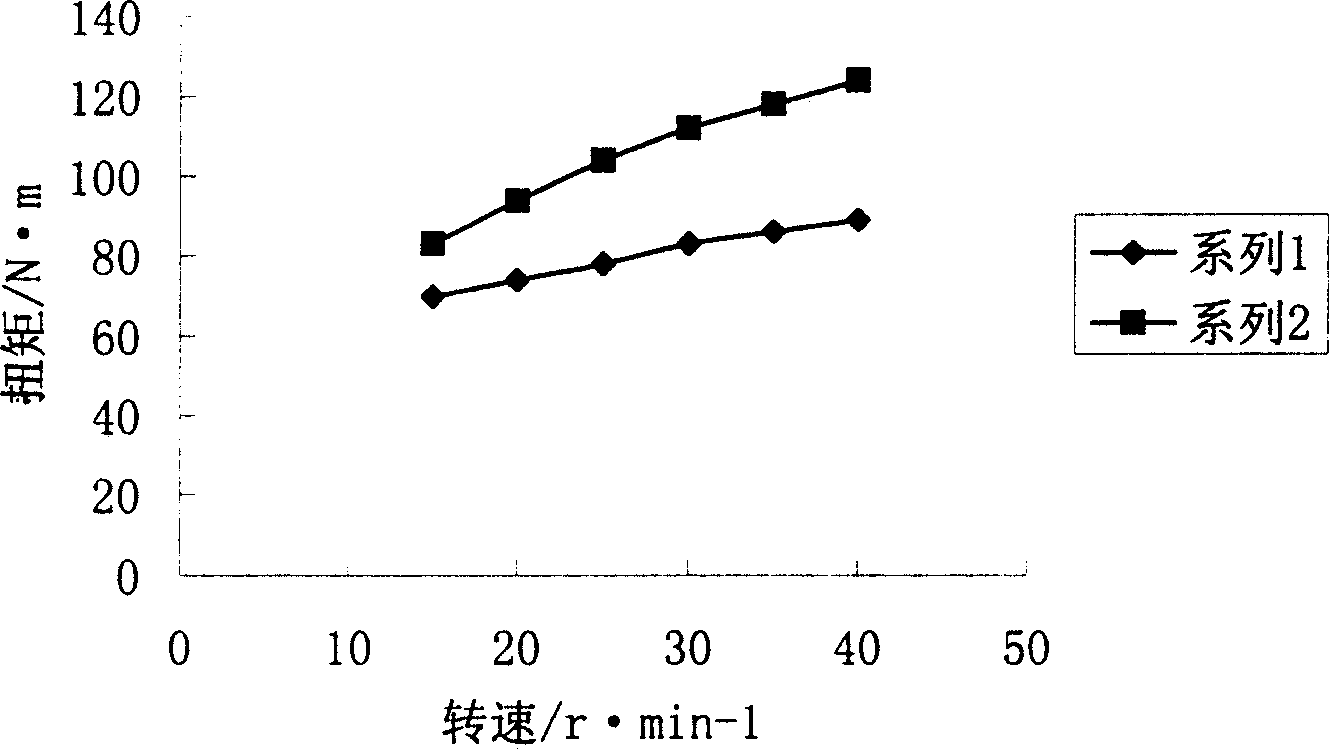

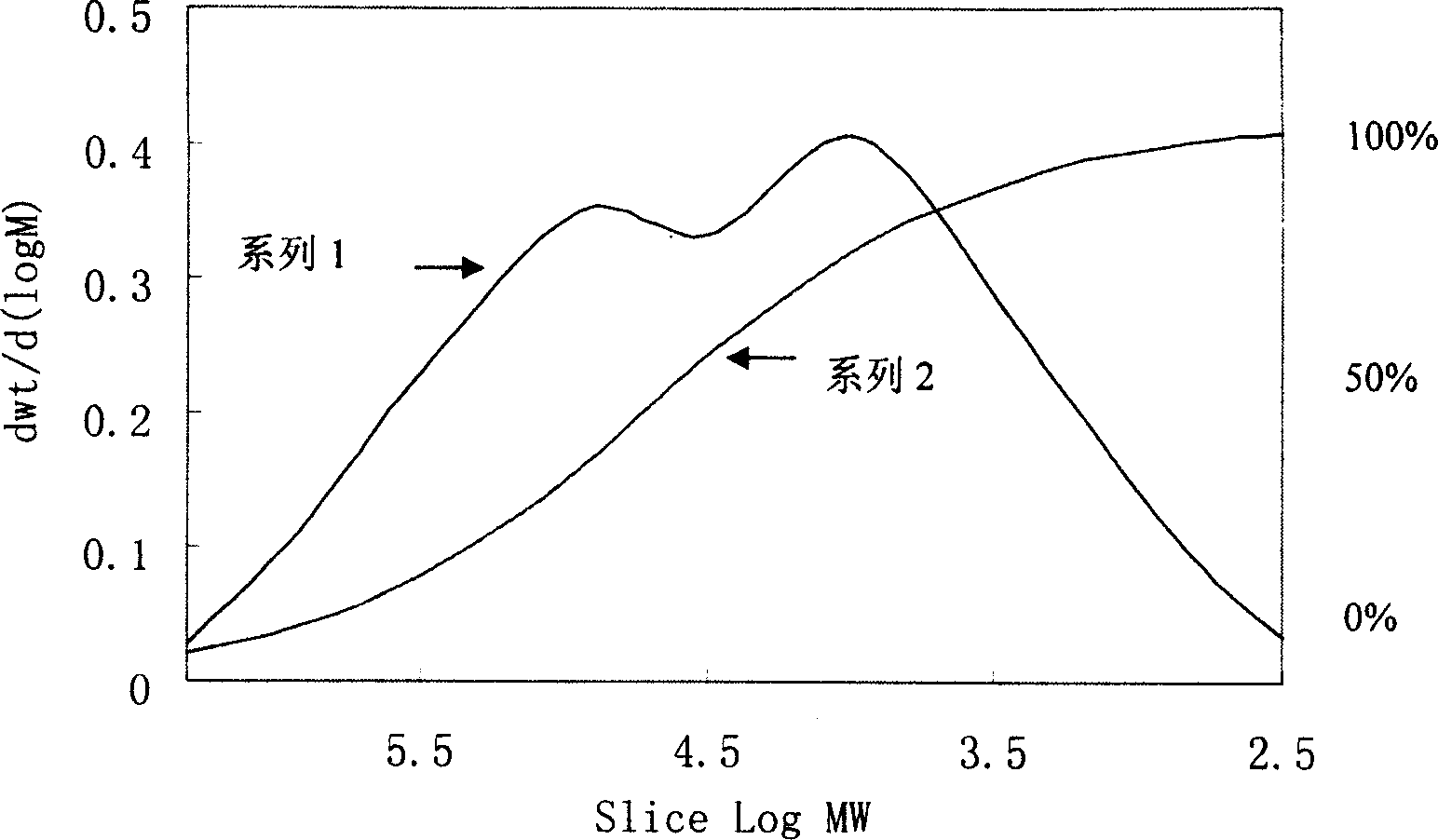

[0050] According to the present invention, changing the hydrogen addition amount of the first reactor and the second reactor, that is, changing the hydrogen / ethylene ratio of the first reactor and the second reactor, can control the polymerization of the first reactor and the second reactor The molecular weight of the product can be used to produce bimodal polyethylene products with different molecular weights and distributions. By changing the amount of butene added in the second reactor, that is, by changing the comonomer content in the second reactor, bimodal high-density polyethylene products with different environmental stress cracking resistance can be produced.

[0051] In Example 2, by changing the process control parameters in Example 1, especially the hydrogen / ethylene ratio and the flow rate of butene-1, bimodal high-density polymers with different molecular weights and their distributions and different environmental stress cracking resistance properties can be obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com