Cerium halide flashing crystal and its preparation method

A technology of scintillation crystals and single crystals, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of short decay time, poor time resolution, high light output, etc., and achieve easy batch growth, low growth cost, and fast decay time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Cerium chloride (CeCl 3 ) growth of single crystals by the crucible drop method.

[0047] Raw material: 99.99% anhydrous cerium chloride (CeCl 3 ) 40.0 grams;

[0048] crucible:

[0049] It is fired from a transparent quartz tube with a diameter of 30 mm and a length of 20 cm. The crucible 7 is axisymmetric, with a conical bottom and a taper of 60 degrees;

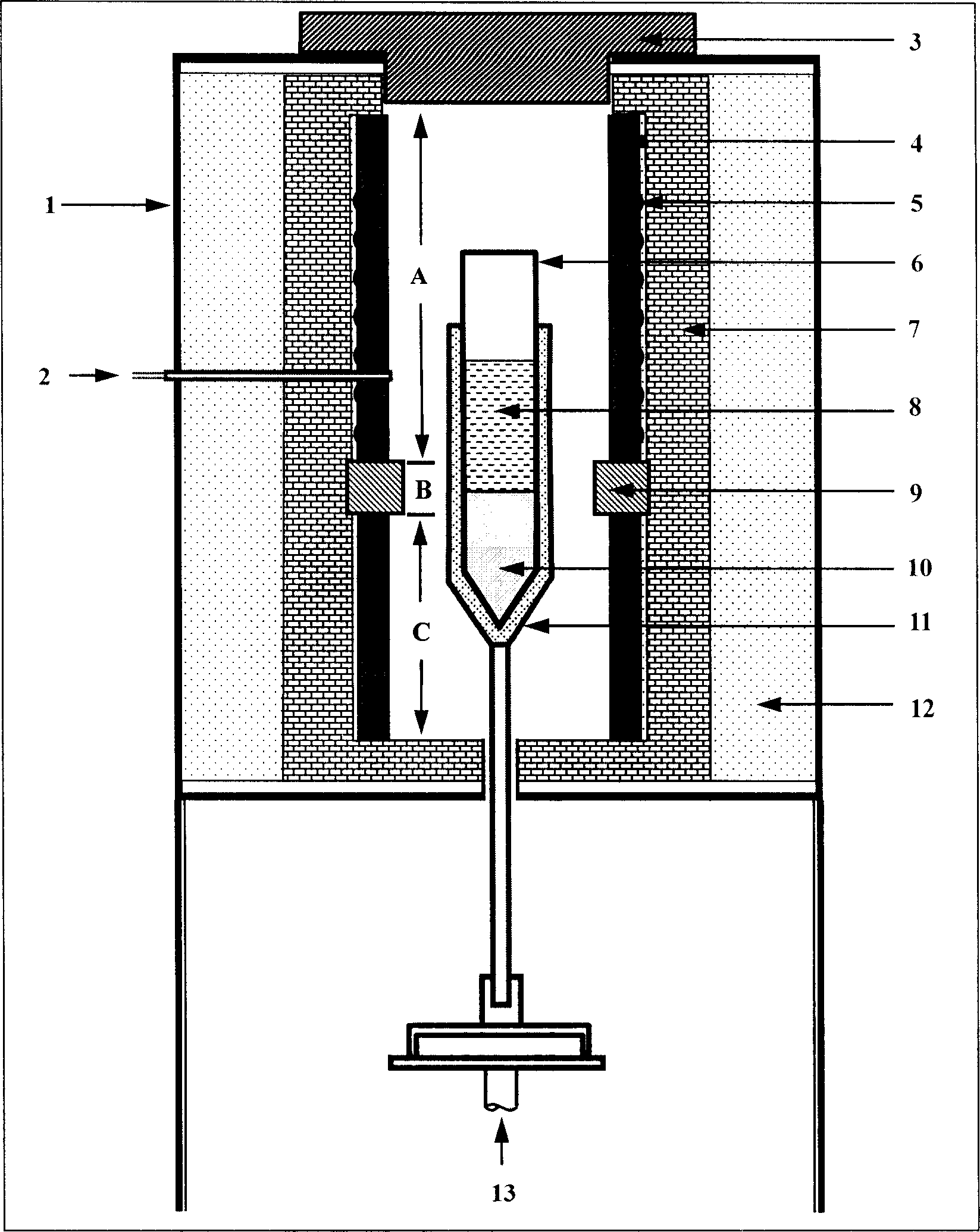

[0050] Crystal growth furnace:

[0051] A crucible descending furnace made of high-temperature refractory materials, including a furnace shell 1; a furnace body composed of insulation materials 12, refractory bricks 7, furnace tubes 4, and furnace wires 5. There is a hole in the center of the lower bottom surface of the furnace body, and the upper part of the furnace body Covered with a furnace mouth plug 3; the hearth of the furnace body is divided into a high temperature zone A, a crystallization zone B and a low temperature zone C by the bayonet 9; the control thermocouple 2 penetrates laterally and is embedd...

Embodiment 2-8

[0056] Embodiment 2-8, comparative example 1-2

[0057] In embodiment and comparative example, the purity of raw material used is respectively: CeCl 3 99.99%, CeBr 3 99.99%, CeI 3 99.9%, LaCl 3 99.99%. The quartz crucibles are all made of transparent quartz tubes with a diameter of 30 mm and a length of 20 cm. The crucibles are axisymmetric and have a conical bottom. The method of operation is the same as in Example 1, and the raw materials used in each example, as well as the main process parameters of the angle of the bottom of the cone and the descending growth, are listed in Table 2.

[0058]

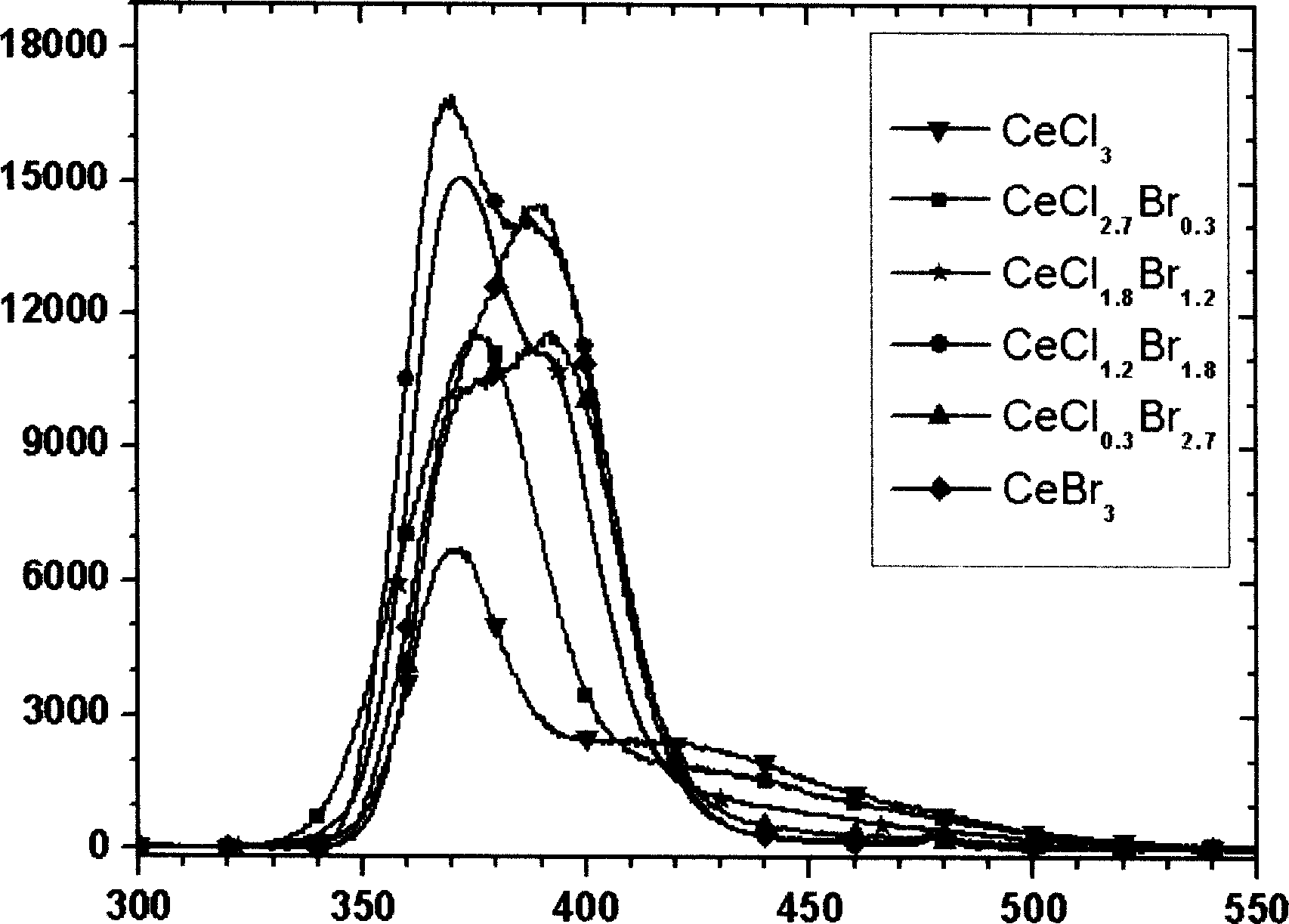

Embodiment 9-23

[0060] The operation method is the same as in Example 1. The chemical composition of the crystals grown in each example, the mole percentage of the corresponding raw materials, the taper of the crucible bottom and the main process parameters of the descending growth are listed in Table 3.

[0061] Table three

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com