Alcohol-water compounded solvents coprecipitation method of preparing yttrium aluminium garnet nano-powder

A technology of yttrium aluminum garnet and nano-powder is applied in rare earth metal compounds, chemical instruments and methods, alumina/aluminum hydroxide and other directions, which can solve the problems of complicated operation and constant pH value of difficult systems, and achieves simple process, Easy to operate, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

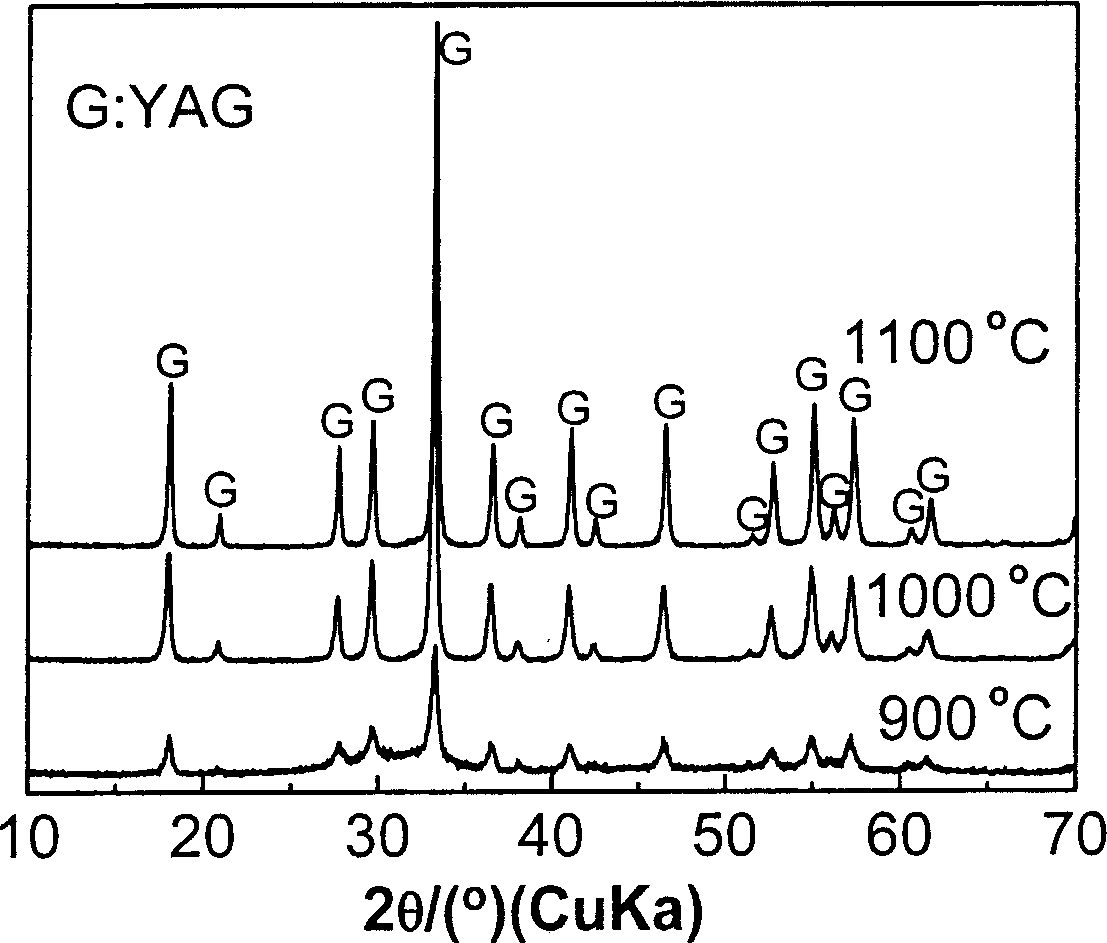

[0025] 0.03mol Y(NO 3 ) 3 and 0.05mol NH 4 Al(SO 4 ) 2 Dissolved in 600ml deionized water to prepare Al 3+ Concentration is 0.083mol / L mixed salt solution, and the volume ratio of ethanol and water is 1: 1 ethanol-water composite solvent preparation 2000ml concentration is 0.4mol / L NH 4 HCO 3 solution; titrate the prepared mixed salt solution to 2000ml NH at a rate of 200ml / h under normal pressure and 15°C 4 HCO 3The solution was stirred continuously during the titration. After the titration, age at normal pressure and 15°C for 8 hours; vacuum filter the aged precipitation solution to obtain a milky white precipitate, then wash the precipitate with deionized water for 3 times to remove impurity ions, and then Wash twice with absolute ethanol to remove water; put the washed white precipitate into a drying oven, and dry at normal pressure and 90°C for 24 hours to obtain a YAG precursor. Divide the YAG precursor into three parts, respectively ℃, 1000℃, 1100℃ for 2 hours,...

Embodiment 2

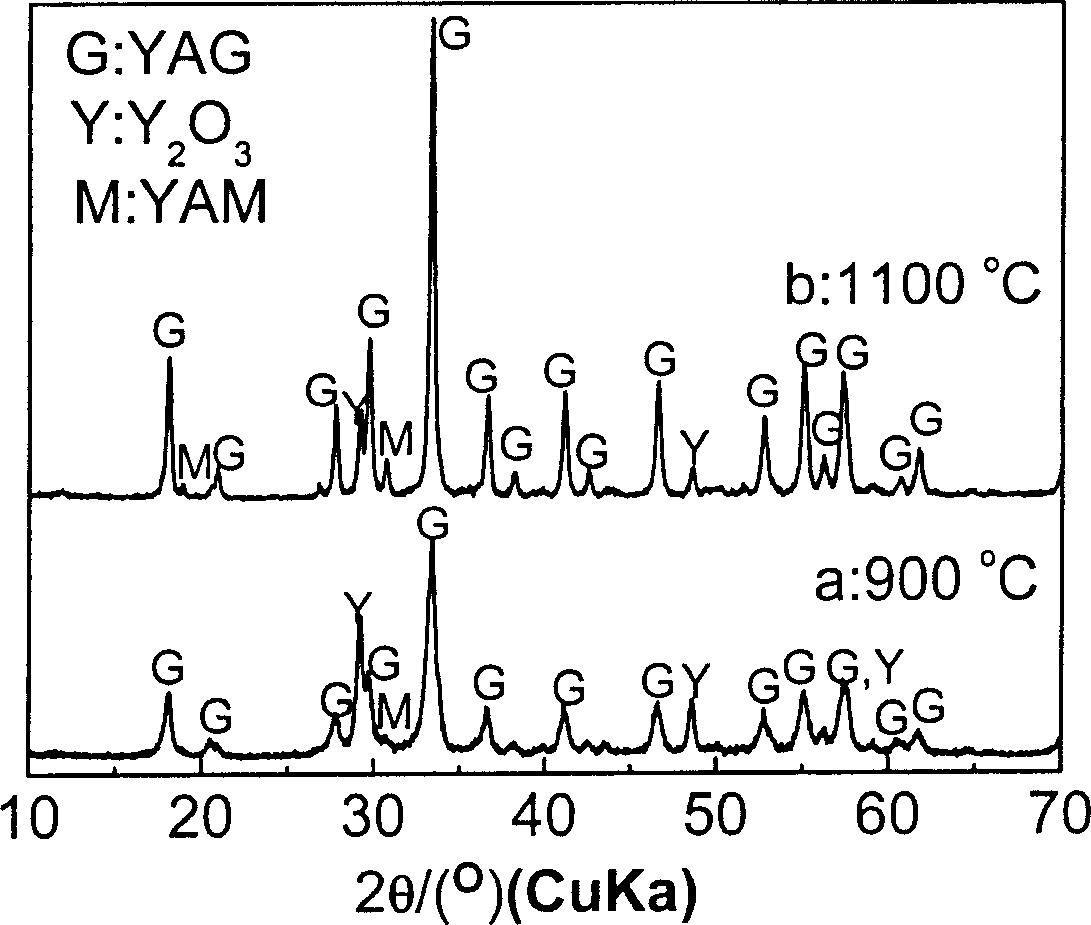

[0028] 0.072mol Y(NO 3 ) 3 and 0.12mol Al((NO 3 ) 3 Dissolved in 600ml deionized water to prepare Al 3+ Concentration is 0.2mol / L mixed salt solution, and the volume ratio of ethanol and water is 0.2:1 ethanol-water composite solvent to prepare 1200ml of NH with a concentration of 1.5mol / L 4 HCO 3 solution; titrate the prepared mixed salt solution to 1200ml NH at a rate of 180ml / h under normal pressure and 15°C 4 HCO 3 The solution was stirred continuously during the titration. After the titration, age at normal pressure and 15°C for 10 hours; vacuum filter the aged precipitate solution to obtain a white precipitate, then wash the precipitate 3 times with deionized water to remove impurity ions, and then Wash twice with absolute ethanol to remove water; put the washed white precipitate into a drying oven, and dry at normal pressure and 90°C for 24 hours to obtain a YAG precursor. Divide the YAG precursor into three parts, respectively ℃, 1000℃, 1100℃ for 3 hours, and t...

Embodiment 3

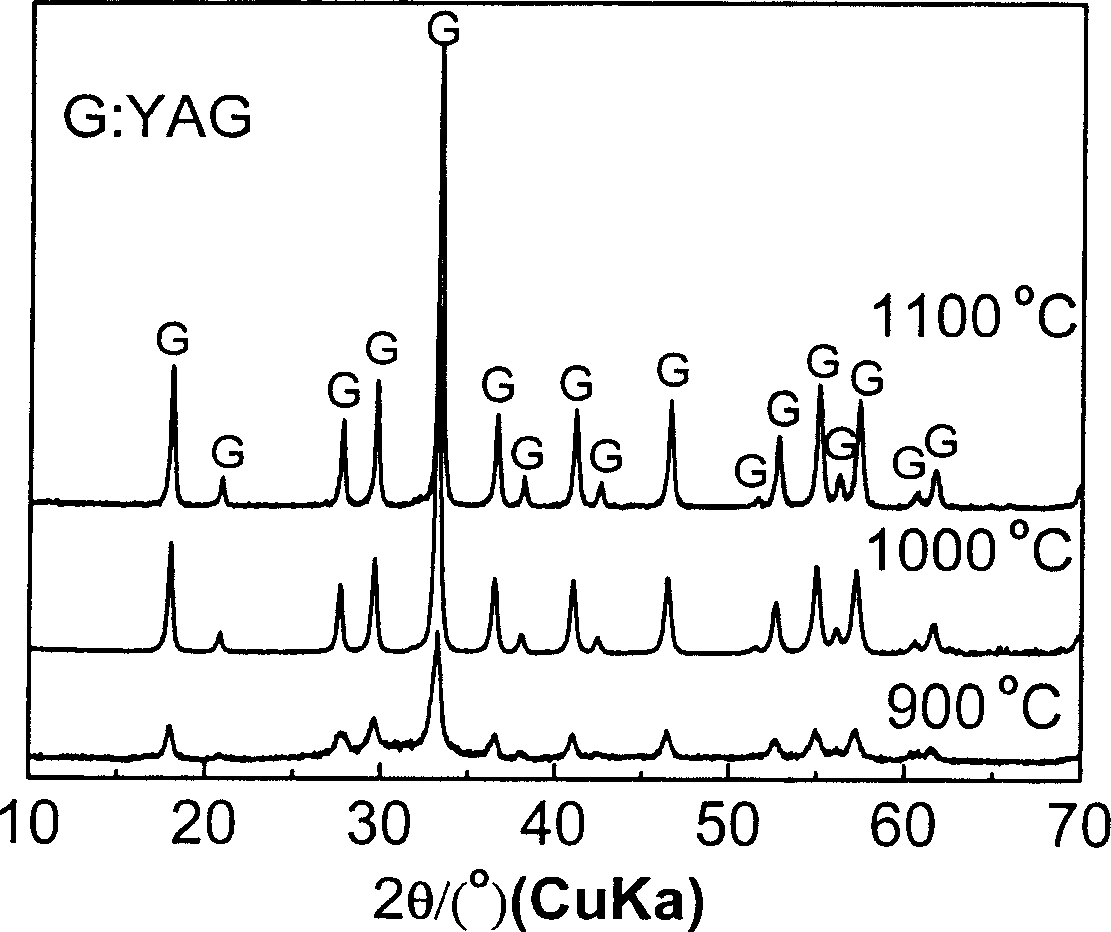

[0030] 0.03mol YCl 3 and 0.05mol NH 4 Al(SO 4 ) 2 Dissolved in 2000ml deionized water to make Al 3+ Concentration is 0.025mol / L mixed salt solution, and the volume ratio of ethanol and water is 0.5:1 ethanol-water composite solvent to prepare 800ml of NH with a concentration of 1mol / L 4 HCO 3 solution; titrate the prepared mixed salt solution to 800ml NH 4 HCO 3 The solution was stirred continuously during the titration. After the titration is finished, age at normal pressure and 10°C for 5 hours; carry out vacuum suction filtration to the aged precipitate solution to obtain a white precipitate, then wash the precipitate with deionized water 3 times to remove impurity ions, and then Wash twice with absolute ethanol to remove water; put the washed white precipitate into a drying oven, dry at normal pressure and 90°C for 24 hours to obtain a YAG precursor, and roast the YAG precursor at 1000°C for 2 hours to obtain The product is detected by X-ray diffractometer (XRD, D / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com