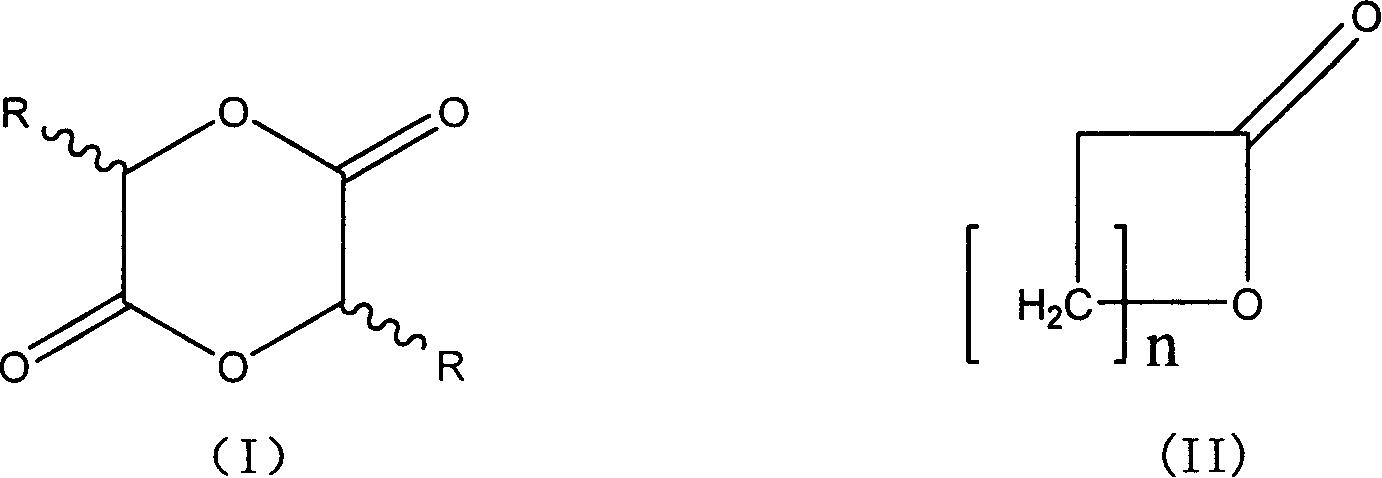

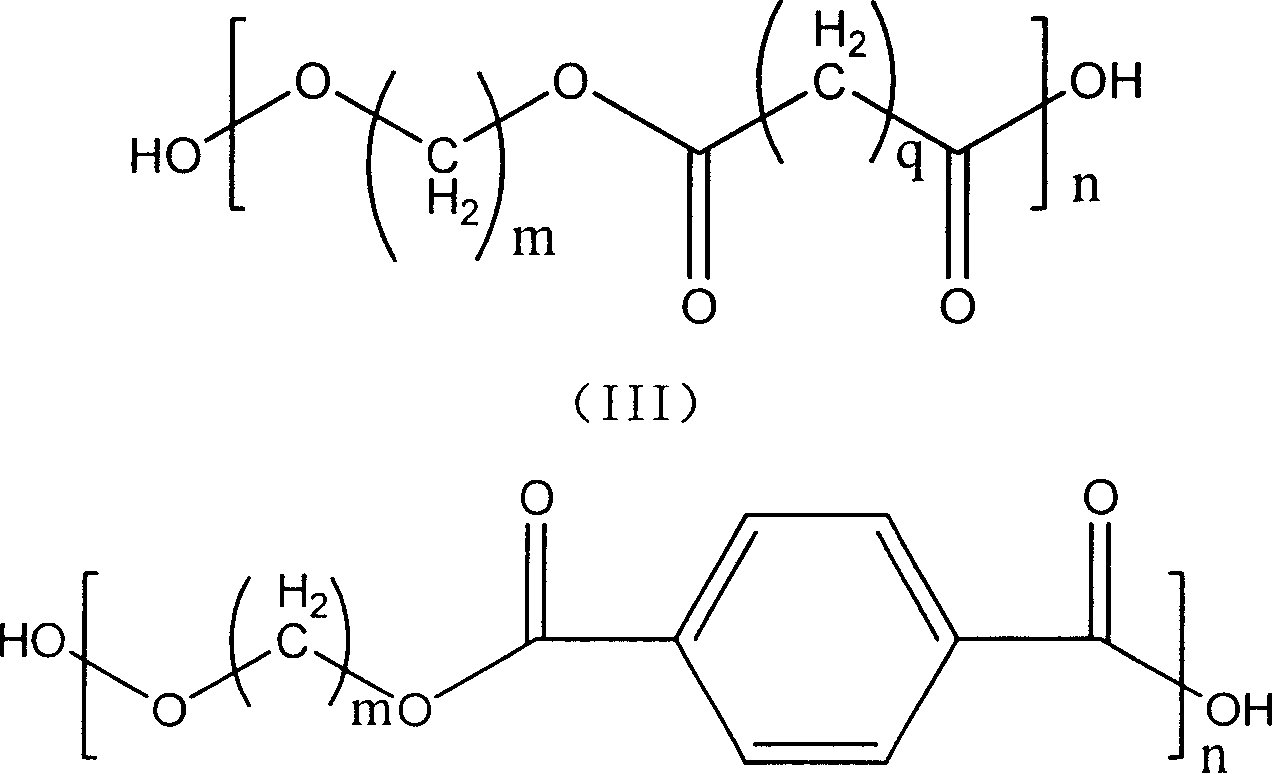

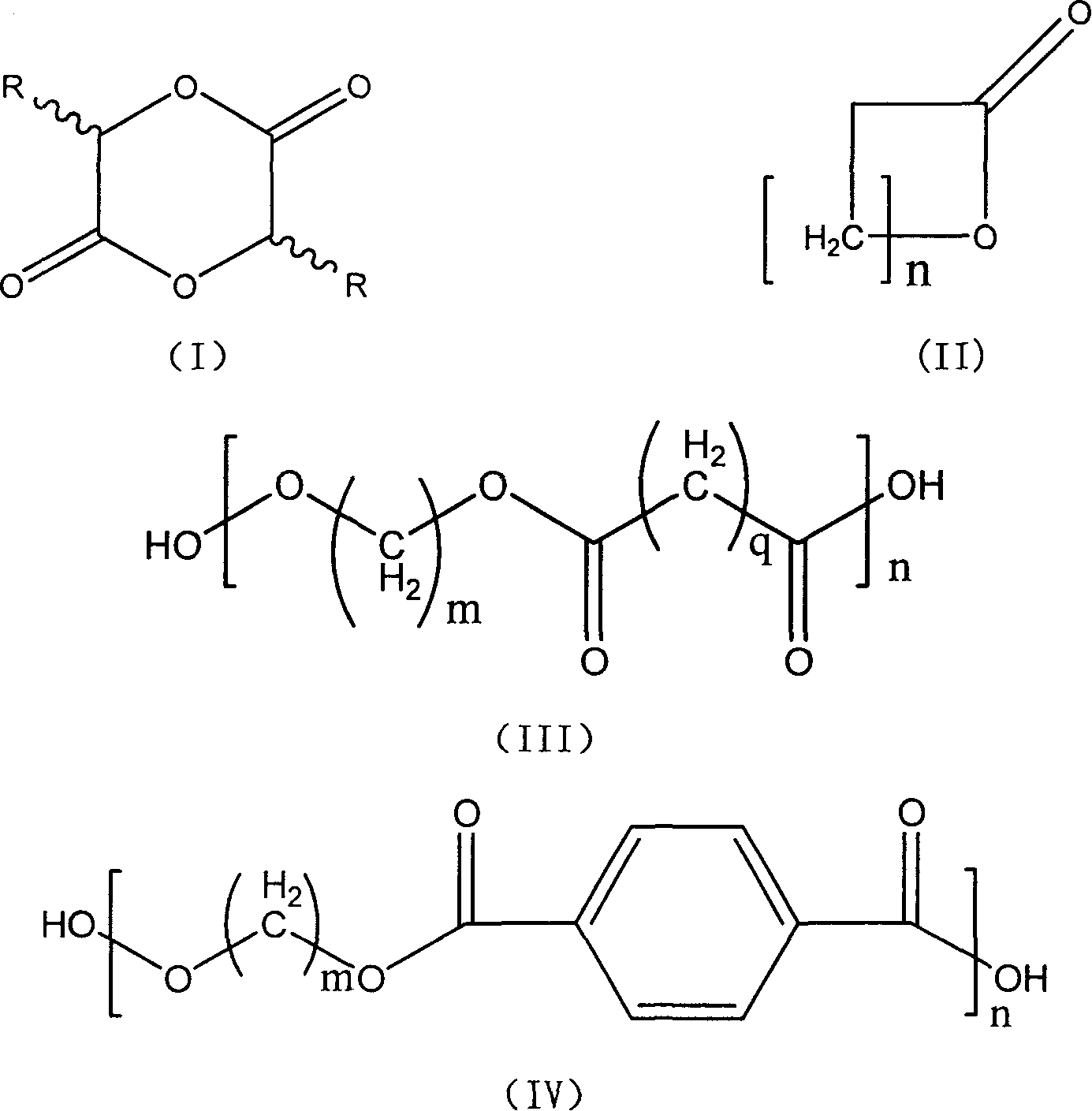

Method of preparing full biodegradation copolymer from ring-opening polymer

A technology of ring-opening polymerization and full degradation, which is applied in the field of ring-opening polymerization of hydroxyl-terminated polyester oligomers to prepare biodegradable copolymers, achieving the effects of easy industrial integrated production, high molecular weight, and fast degradation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 800g of LLA refined and purified by ethanol recrystallization method, M w =(4-5)×10 4 Hydroxyl-terminated polybutylene adipate (PBA) 200g, stannous octoate 0.8g adds vacuum reactor, fills with N 2 After 2-3 repeated operations, the system pressure drops below 60Pa, and the reaction temperature rises to 135°C. After 12 hours of reaction, N 2 Gas protection discharge, get M w =(1.5-3)×10 5 The poly(butylene adipate-co-L-lactide) biodegradable resin.

Embodiment 2

[0029] 800g of DLLA refined and purified by ethanol recrystallization method, M w =(1-2)×10 4 Hydroxyl-terminated polybutylene terephthalate (PBT) 200g, aluminum isopropoxide 1.6g is added to the vacuum reactor, filled with N 2 After 2-3 repeated operations, the system pressure drops below 60Pa, and the reaction temperature rises to 140°C. After 10 hours of reaction, N 2 Gas protection discharge, get M w =(1.5-3)×10 5 The poly(butylene terephthalate-co-D, L-lactide) biodegradable resin.

Embodiment 3

[0031] 800g of DLLA refined and purified by ethanol recrystallization method, M w =(3-5)×10 4 80g of hydroxyl-terminated polybutylene succinate (PBS) and 2.4g of tetrabutyl titanate were added to the vacuum reactor, filled with N 2 After 2-3 repeated operations, the system pressure drops below 60Pa, and the reaction temperature rises to 130°C. After 15 hours of reaction, N 2 Gas protection discharge, get M w =(1.5-3)×10 5 The poly(butylene succinate-co-D, L-lactide) biodegradable resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com