Centrifuge hot press sintering method and device of metal bonding agent extra hard material grinding wheel

A technology of metal bond and hot pressing sintering, which is applied in the direction of grinding equipment, metal processing equipment, grinding/polishing equipment, etc., can solve the problem of uneven axial density distribution, achieve simple equipment, reduce production costs, The effect of high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

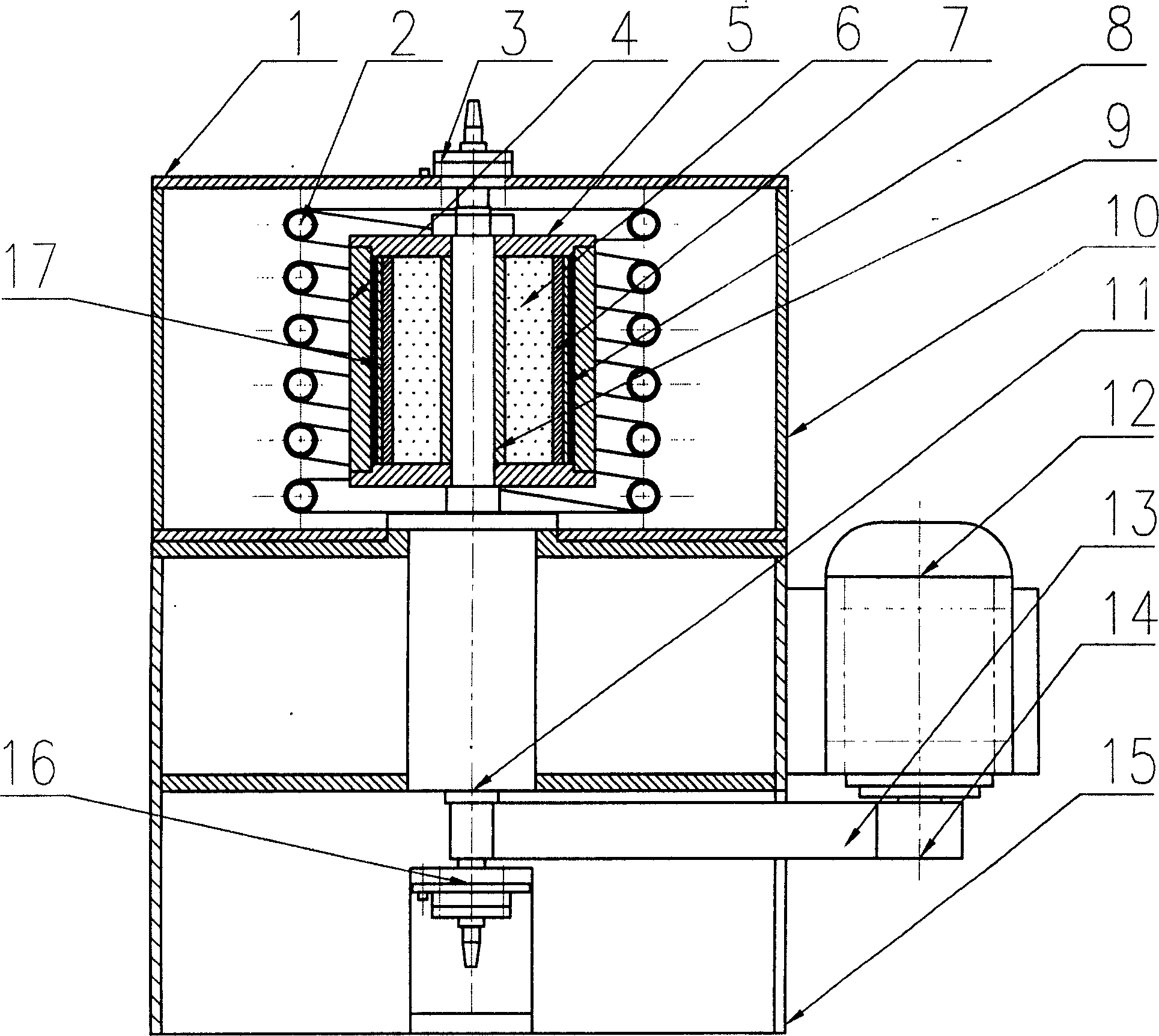

[0024] The present invention comprises the steps:

[0025] A. In the mold cavity composed of molds (4) and (5), put the grinding wheel working layer material (8), transition layer material (17), isolation layer (7) and centrifugal medium (6) from outside to inside in the radial direction Arranged in layers, the mold is fixed on the main shaft mechanism (11); the working layer material (8) of the grinding wheel includes abrasive material and metal bond;

[0026] B. Start the motor (12) to drive the mold, the centrifugal medium and the molding material composed of the grinding wheel working layer material and the transition layer material to rotate at high speed, and the centrifugal medium pressurizes the molding material through the isolation layer;

[0027] C. Start the heating device, heat up and pressurize the molding material, and turn off the heating power after the centrifugal hot pressing sintering is completed;

[0028] D. Cool down to below 300°C, stop the rotation, a...

Embodiment 2

[0032] Method of the present invention comprises the steps:

[0033] Design and manufacture Φ100mm×150mm (height dimension)×3mm (thickness of abrasive layer of grinding wheel) / 7mm (thickness of non-abrasive layer of grinding wheel, also called transition layer)

[0034] The weight percent of the binder is: Cu 50-80%, Co 10-15%, Fe 10-15%, Ni 5-10%,

[0035] Sn 10-20%, Zn 0-5%.

[0036] Diamond concentration: 100%, particle size 70 / 80.

[0037] Concrete preparation method is as follows:

[0038] A. Mixing

[0039] First weigh the various binder powders required by the above formula according to the formula share and put them into a two-dimensional or three-dimensional mixer commonly used in the superabrasive tool industry to fully mix (dry mix) evenly for 40 minutes. Then add the diamond and mix well (dry mixing) evenly for 30 minutes.

[0040] B. Granulation

[0041] Add the above mixture into the general granulation agent (WS120 temporary molding a...

Embodiment 3

[0053] Method of the present invention comprises the steps:

[0054] Design and manufacture Φ100mm×150mm (height dimension)×5mm (thickness of abrasive layer of grinding wheel) / 5mm (thickness of non-abrasive layer of grinding wheel, also called transition layer)

[0055] The weight percent of the binder is: Cu 50-80%, Co 10-15%, Fe 10-15%, Ni 5-10%,

[0056] Sn 15-20%, Zn 0-5%.

[0057] Diamond concentration: 75%, particle size 140 / 170.

[0058] Concrete preparation method is as follows:

[0059] A. Mixing

[0060] First weigh the various binder powders required by the above formula according to the formula share and put them into a two-dimensional or three-dimensional mixer commonly used in the superabrasive tool industry to fully mix (dry mix) evenly for 40 minutes. Then add diamond and mix well (dry mixing) evenly for 40 minutes.

[0061] B. Granulation

[0062] Add the above mixture into the general granulation agent (WS120 temporary molding agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com