Liquid-conveying metallorganics chemical vapour deposition apparatus

A chemical vapor deposition, metal organic technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve problems such as large vapor pressure difference and difficult to control transportation, and achieve instant discharge and large application range. , the effect of avoiding complexity problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

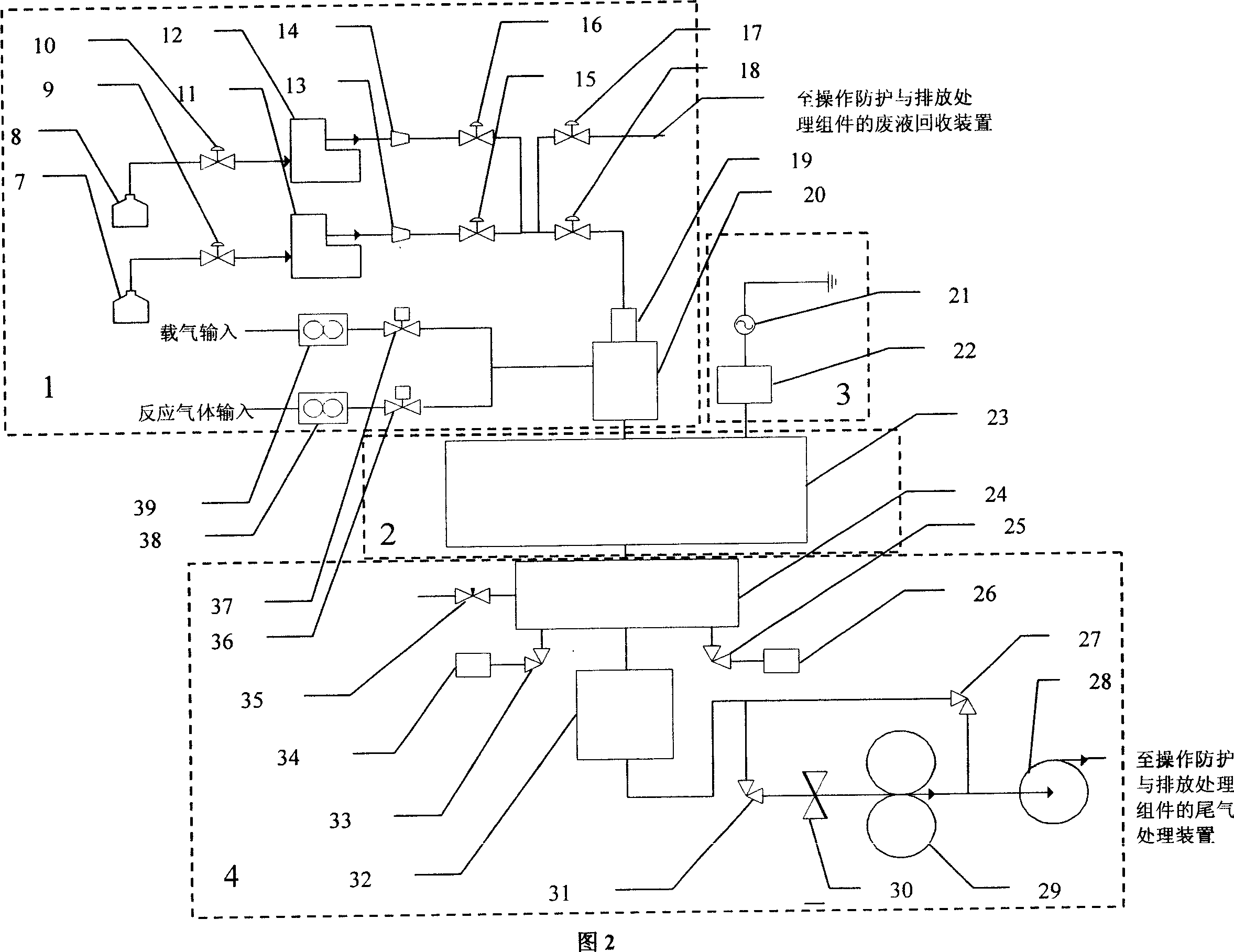

[0033] Embodiment 1: Referring to Fig. 1, the metal-organic chemical vapor deposition equipment for liquid delivery includes a reaction chamber component, a radio frequency discharge plasma component, a vacuum component, an operation protection and emission treatment component, an electric control component, and the radio frequency discharge plasma component passes through The output electrode is connected to the electrode of the gas distribution box of the reaction chamber assembly, the gas output pipe of the reaction chamber assembly is connected to the pneumatic valve of the vacuum assembly, and the exhaust gas output channel of the vacuum assembly is directly connected to the exhaust gas treatment device of the operation protection and emission treatment assembly. The total equipment also includes a multi-component vaporization component 1, which is a replaceable integrated component, mainly composed of multiple liquid source delivery channels, two gas delivery channels, ato...

Embodiment 2

[0037] Embodiment 2: The overall equipment is the same as in Embodiment 1. The vacuum assembly 4 of the present invention also includes a powder catcher 32. The powder catcher 32 is composed of an upper part 58 of the catcher and a lower part 63 of the catcher which can be easily disassembled. The upper and lower parts of the catcher are fastened and loosened. The powder catcher 32 is a cylindrical structure. The outer wall of the cylinder is fixed with a cooling device 66. The upper end of the powder catcher 32 is connected to the reaction chamber assembly 2 through the gas storage cylinder 24. It is divided into two paths, one path is connected to the dry pump 28 through the DN25 angle valve 27, and the other path is connected to the Roots pump 29 through the DN50 angle valve 31.

[0038] The cooling device 66 is made of a stainless steel tube that is evenly wound and welded on the outer wall of the cylinder, and liquid nitrogen is injected into the upper part 58 of the catch...

Embodiment 3

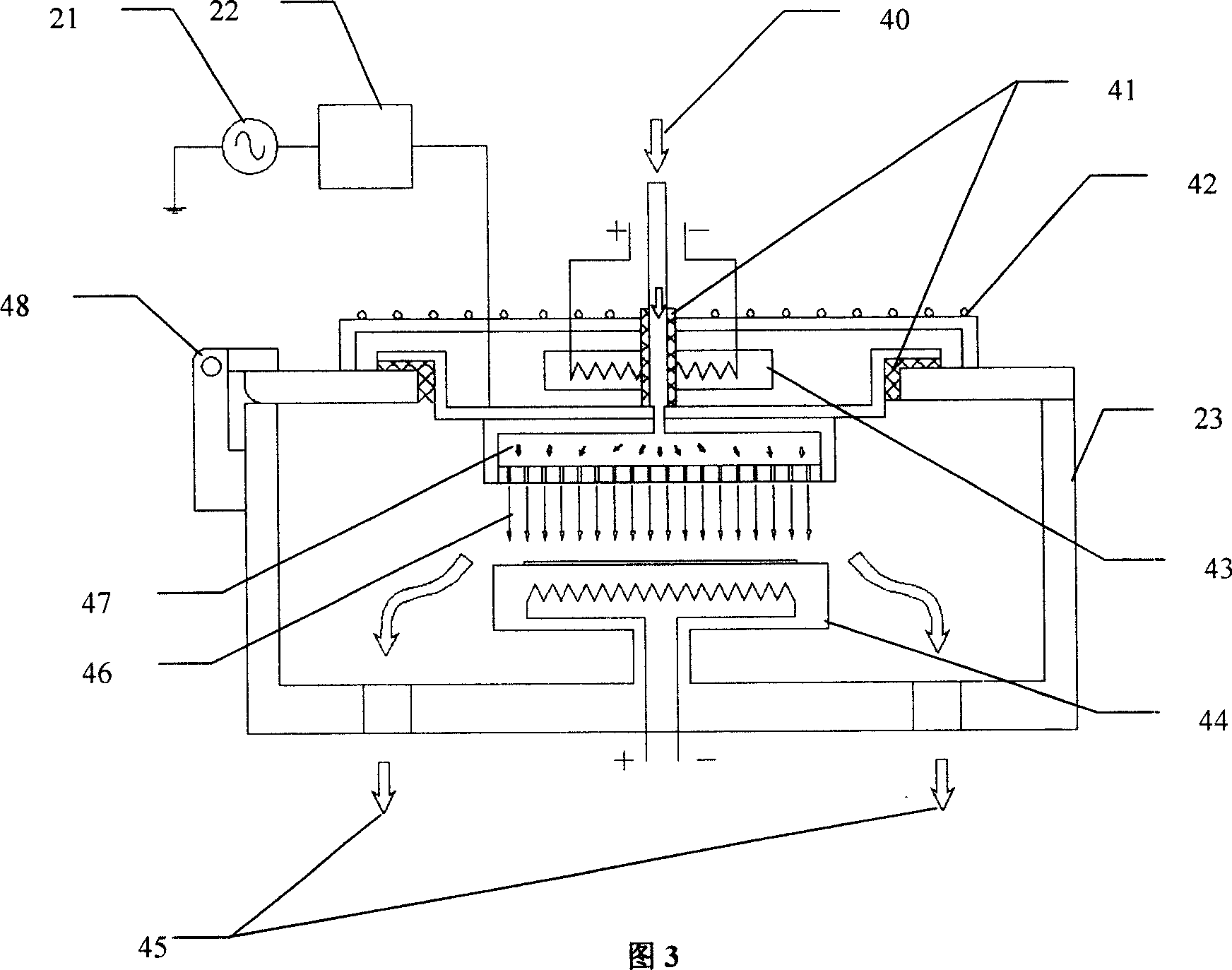

[0039] Embodiment 3: overall equipment is the same as embodiment 2, referring to Fig. 3, the upper and lower electrodes in the reaction chamber assembly 2 are adjustable spacing electrodes, that is, the upper electrode flat plate connected to the radio frequency discharge plasma assembly 3 is served by the gas distribution box 47, and the gas distribution Small holes are evenly distributed on the bottom of the box 47. The lower electrode is formed by the substrate table 44. The distance between the two electrodes is adjusted by increasing or decreasing the number of backing plates. The backing plate is in close contact with the upper electrode and has a constant thickness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com