Method for preparing micro-flowing injection type chemical luminous chip

A chemiluminescence and injection technology, applied in chemiluminescence/bioluminescence, chemical analysis by microanalysis, and analysis by chemical reaction of materials, etc., can solve the problem of poor controllability of microstructure size and low production efficiency , poor surface quality and other problems, to achieve the effect of high production efficiency, low cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

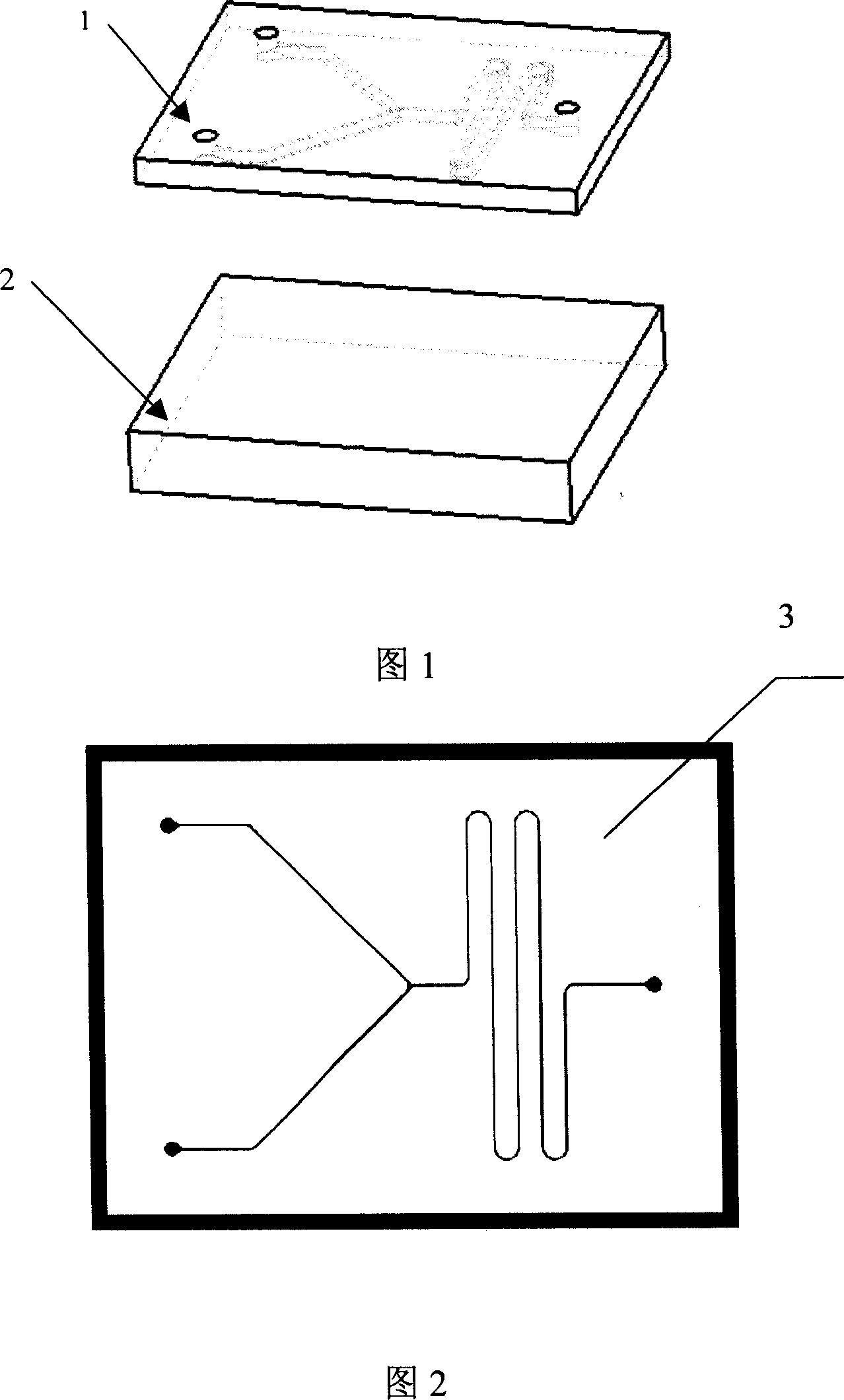

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] 1) Surface cleaning of silicon wafers: The cleaning of silicon wafers is mainly to remove oil stains and various adsorbed impurity particles on the surface of silicon wafers to obtain a clean surface. Wipe the surface of the silicon wafer repeatedly with a cotton swab dipped in acetone and absolute ethanol successively. Then place the silicon chip in an acetone solution, ultrasonically clean it for 4-8 minutes, take it out, put it directly into absolute ethanol, and then clean it ultrasonically for 5-10 minutes. After cleaning, the surface of the silicon wafer was repeatedly rinsed with deionized water, and finally dried with high-purity nitrogen.

[0012] 2) Surface hydrophobic modification treatment: put the cleaned silicon chip into a mixed solution of sulfuric acid and hydrogen peroxide with a mass concentration of 98% for 10 to 20 minutes, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com