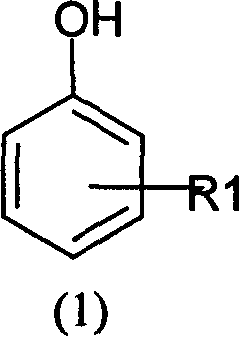

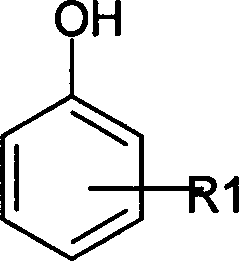

Use of aluminium nitrate in phenol derivative nitrofication

A technology of aluminum nitrate and aromatic hydrocarbon derivatives, applied in the preparation of nitro compounds, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

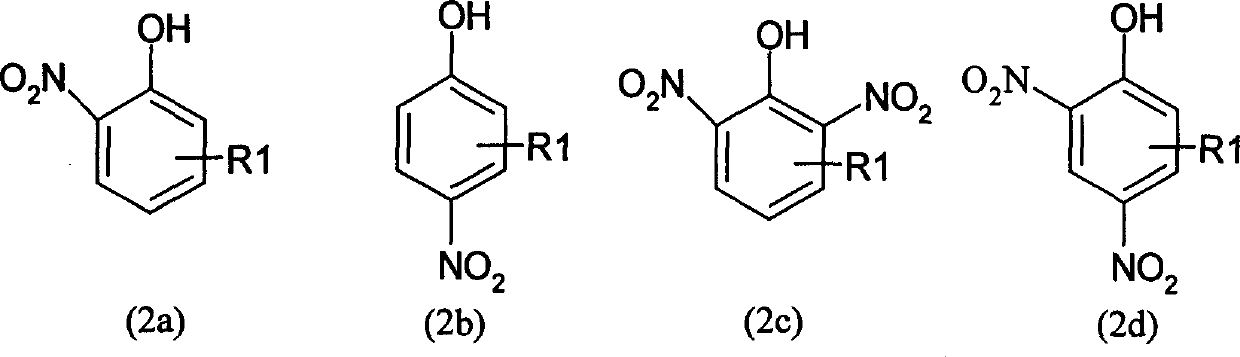

[0026] Embodiment 1: the reaction of p-cresol and aluminum nitrate (1: 1)

[0027] 1.08 g of p-cresol was dissolved in 25 ml of ethanol, then 3.75 g of aluminum nitrate hydrate (Al(NO 3 ) 3 9H 2 O), stirred and refluxed for 2 hours, the solution was brown. The solvent was recovered by rotary evaporation, 25 ml of water was added, extracted three times with 25 ml of diethyl ether, dried over anhydrous sodium sulfate, distilled off diethyl ether to obtain 1.10 g of oily liquid. The total yield is 71.9%, wherein the content of ortho products is 20.9%, and the content of disubstituted products is 79.0%.

[0028] ESI-MS m / z[M-H] - =152.5 (15%), 197.5 (100%).

Embodiment 2

[0029] Embodiment 2: the reaction of o-cresol and aluminum nitrate (1: 1)

[0030] 1.08 grams of o-cresol were dissolved in 25 milliliters of ethanol, then 3.75 grams of aluminum nitrate hydrate (Al(NO 3 ) 3 9H 2 O), stirred and refluxed for 2 hours, the solution was brown. The solvent was recovered by rotary evaporation, 25 ml of water was added, extracted three times with 25 ml of ether, dried over anhydrous sodium sulfate, and the ether was distilled off to obtain 0.95 g of an oily liquid. The total yield is 62.1%, wherein the ortho product content is 8.7%, the para product content is 31.9%, and the disubstitution product content is 57.8%.

[0031] ESI-MS m / z[M-H] - =152.5 (60%), 197.5 (100%).

Embodiment 3

[0032] Embodiment 3: the reaction of m-cresol and aluminum nitrate (1: 1)

[0033] 1.08 grams of m-cresol were dissolved in 25 milliliters of ethanol, then 3.75 grams of aluminum nitrate hydrate (Al(NO 3 ) 3 9H 2 O), stirred and refluxed for 2 hours, the solution was brown. The solvent was recovered by rotary evaporation, 25 ml of water was added, extracted three times with 25 ml of ether, dried over anhydrous sodium sulfate, and the ether was distilled off to obtain 0.95 g of an oily liquid. The total yield is 75.3%, wherein the ortho product content is 41.2%, the para product content is 44.6%, and the disubstitution product content is 13.5%.

[0034] ESI-MS m / z[M-H] - =152.5 (60%), 197.5 (100%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com