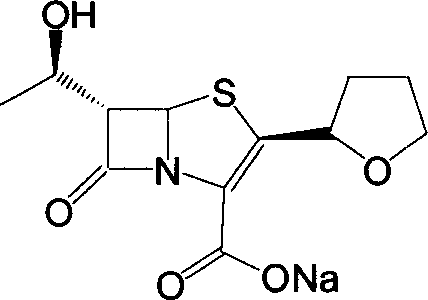

Industrial production of Fallopeinan sodium

A synthesis method and a technology for an intermediate, which are applied in the field of industrialized production of faropenem sodium, can solve the problems of high production cost of faropenem sodium, difficulty in realizing large-scale industrial production, and the like, and achieve reaction conditions that are easy to realize, low in cost, and high in yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

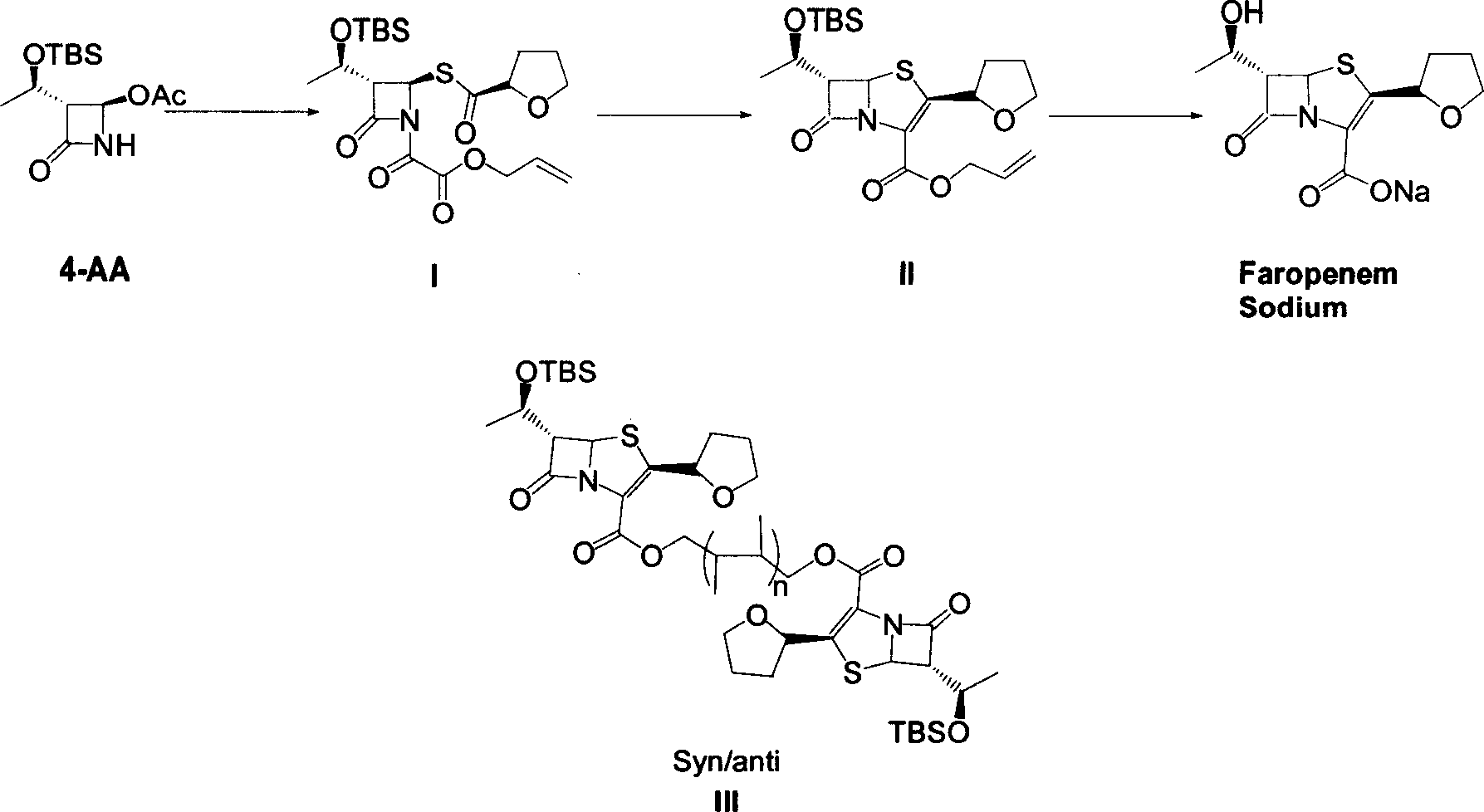

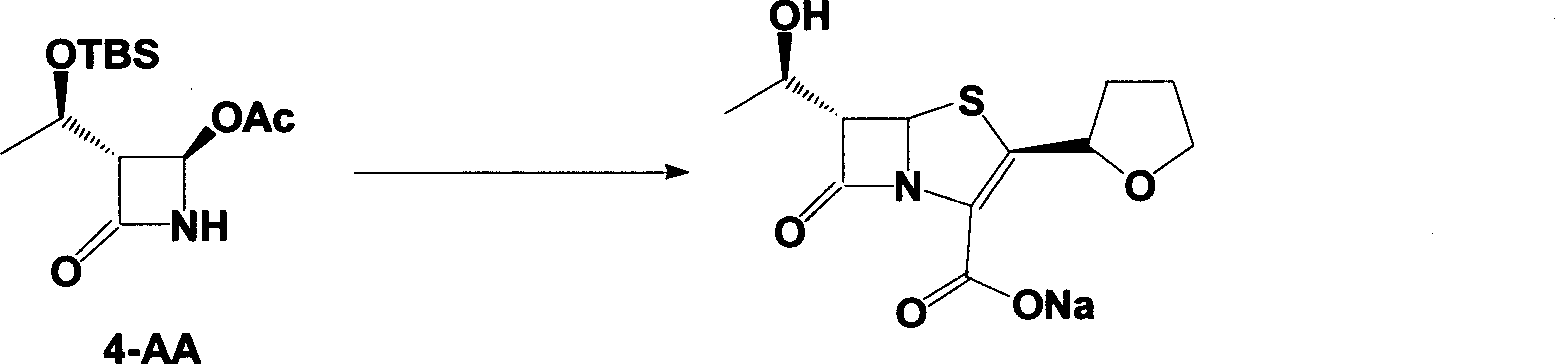

Method used

Image

Examples

Embodiment 1

[0031] Add 240g (R)-tetrahydrofuran-2-thioformic acid and 490g 4-AA into a 2000ml three-necked flask, add 1200ml ethyl acetate to it, and slowly add about 400ml 4N NaOH dropwise after dissolving to adjust the pH to 12-13 , and the reaction was stirred until the reaction was complete. Extract with 1500ml ethyl acetate, collect the organic phase, wash with brine, and dry over anhydrous sodium sulfate. The condensate (440 g of colorless viscous liquid) was obtained by spin-drying under reduced pressure, which was directly used in the next step.

Embodiment 2

[0032] Embodiment 2 (lower alkoxy oxalyl chloride refers to propoxy oxalyl chloride):

[0033] The condensate obtained in Example 1 was dissolved in 2000ml of dichloromethane, placed in a 3000ml three-necked flask, and 453.0ml of pyridine was added, cooled to 0°C in an ice-water bath, and 355g of propoxy oxalyl chloride was added dropwise at 5-15°C and 350ml of dichloromethane mixture. After the dropwise addition is completed, continue to react under this condition for about 30 minutes. The plate layer monitors that the reaction is complete. Add 1500ml of deionized water. The organic phase is washed with 1500ml of deionized water and 1500ml of saturated sodium bicarbonate solution, and then washed with 1500ml of saturated brine. Dry over anhydrous sodium sulfate. The solvent was distilled off under reduced pressure to obtain the condensate (583 g of colorless solid), which was set aside.

Embodiment 3

[0035] Dissolve 196 g of the solid obtained in Example 2 in 5000 ml of xylene, add 20 g of triethylamine, add it to a 10,000 ml three-necked flask, stir mechanically, heat to reflux with an electric heating mantle, and add 515 ml of triethyl phosphite dropwise, about 120 Minutes dropwise completed. Heat preservation and reflux reaction for 16 hours, and concentrate under reduced pressure to obtain the ring compound (yellow solid 170 g), which is set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com