Production of electrolyte for secondary lithium batteries

A lithium secondary battery and electrolyte technology, applied in the secondary battery, electrolyte battery manufacturing, non-aqueous electrolyte battery and other directions, can solve the problems of deteriorating the performance of electrode materials, hindering the normal performance of battery performance, etc., to improve structural stability and safety Safety, high safety, effect of improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 01

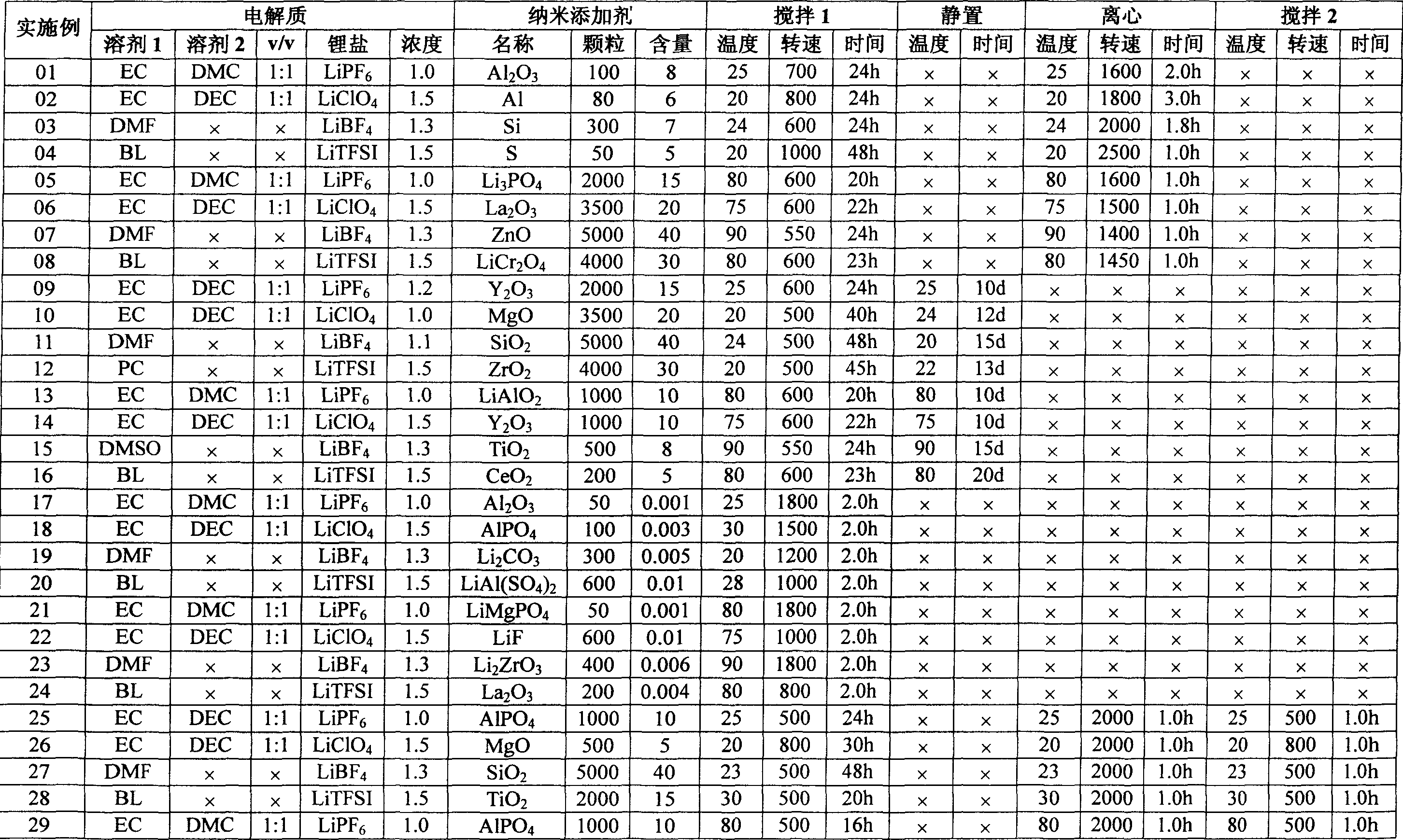

[0039] According to the first method, adding nano-Al 2 o 3 . dry Al with a particle size of 100 nm 2 o 3 Powder was added to 1 mol / L LiPF 6 In the ethylene carbonate (EC) / dimethyl carbonate (DMC) (the volume ratio of the two is 1:1). al 2 o 3 The weight accounts for 8% of the weight of the electrolyte. At room temperature (25° C.), the mixture was mechanically stirred at 700 rpm. After stirring for 24 hours, the solid and liquid parts of the mixture were separated with a centrifuge (rotating at 1600 rpm) (see Table 1 for details). Take the liquid part as the new electrolyte.

[0040] The conductive agent carbon black (10w%), the NMP solution of the binder polyvinylidene fluoride (PVdF, 5w%) and the commercial positive electrode active material LiCoO 2 (85w%) were mixed uniformly to prepare a slurry. The relevant parameters of the cathode active materials are listed in Table 2. The electrode is coated according to the conventional method, and can be used as a positi...

Embodiment 02-04

[0044] A series of new electrolytes were prepared by changing the type, average particle size, stirring and separation speed and temperature of the nano-additive materials used in Example 01 (see Table 1 for details).

[0045] The type and average particle size of the commercially available positive electrode active material were changed (see Table 2 for details), and the positive electrode sheet was prepared according to the method in Example 01. The relevant parameters of the cathode active materials are listed in Table 2.

[0046] The conductive agent carbon black (10w%), the acetone solution of the binder polyacrylonitrile (PAN, 5w%) and the commercial negative electrode active material (85w%) were uniformly mixed to prepare a slurry. The relevant parameters of the negative active materials are listed in Table 2. The electrode is coated according to a conventional method, and can be used as a negative electrode sheet after drying (removing the solvent) and rolling treatme...

Embodiment 05

[0050] According to the first method, adding nano-Li 3 PO 4 . Dry Li with a particle size of 2000 nm 3 PO 4 Powder was added to 1 mol / L LiPF 6 In the ethylene carbonate (EC) / dimethyl carbonate (DMC) (the volume ratio of the two is 1:1). Li 3 PO 4 The weight accounts for 15% of the weight of the electrolyte. The mixture was mechanically stirred at 80° C. at 600 rpm. After stirring for 20 hours, the solid and liquid parts of the mixture were separated using a centrifuge (rotating at 1600 rpm) (see Table 1 for details). Take the liquid part as the new electrolyte.

[0051] According to the conventional method, commercial LiCoO 2 Prepare the positive electrode sheet for the active material (see Table 2 for details), use metal lithium as the negative electrode (the negative electrode is excessive), and use the PP / PE porous film as the separator, and assemble it into a lithium secondary battery in a glove box filled with argon. The new electrolytic solution prepared above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com